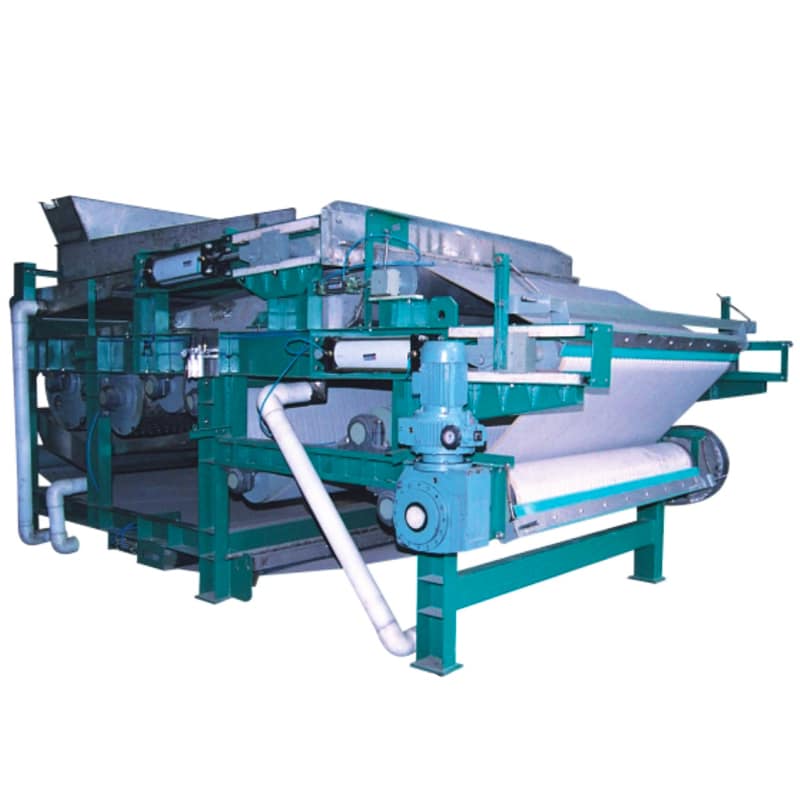

Belt Filter Press

The belt filter press is a kind of filtration equipment that consists of two circular filter belts wrapped around a series of drums of different sizes arranged in sequence, and uses the squeezing and shearing action between the filter belts to remove the water from the slurry (wastewater). It can continuously press and filter a large amount of sludge to reduce the volume of residue, and is characterized by large processing capacity, high dewatering efficiency and long service life.

How does belt filter press press work?

In the pretreatment stage, the solids content of the original slurry is generally very low, and gravity settling or other means are used to increase the concentration of the slurry in order to reduce treatment costs. The concentrated sludge is mixed with polymer flocculant(Usually with polymer preparation system), and fine particles are agglomerated and initially precipitated under the action of flocculant, which is the preparation condition for sludge dewatering.

In the gravity dewatering stage, the belt filter adds the flocculated pretreated sludge to the filter belt, and under the action of gravity, the free water outside the floc is filtered out through the filter belt, thus reducing the water content of the sludge.

In the wedge pre-press dewatering stage, after the sludge is dewatered by gravity, it starts to enter the wedge press section, where the gap between the filter belts gradually decreases, thus starting to be dewatered again by the action of squeezing and shearing. After this stage, the sludge loses its fluidity almost completely, thus ensuring that the sludge will not be extruded in the press dewatering section under normal circumstances.

In the press dewatering stage, the belt filter repeatedly presses and shears the sludge through a carefully designed press roll system, removing a large amount of capillary action water, which gradually reduces the sludge moisture and forms a sludge filter cake. The filter cake is scraped off by the discharge scraper at the separation of the reselected filter belt, and the discharged filter cloth is cleaned and then enters the next cycle.

Under the action of gravity, the filter will filter the sludge in the water. Thus, the water content in the sludge is reduced.

Advantages

- Variable orifice polymer/sludge mixing valve for optimized polymer conditioning

- Larger filter area for higher cake consistency

- High-speed drainage system for significantly higher filtration rates

- Easily adjustable variable wedge compression zone to maximize process rates

- High-quality structural frame materials and components for long-lasting operation