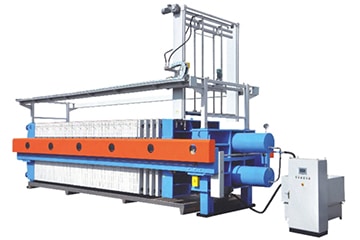

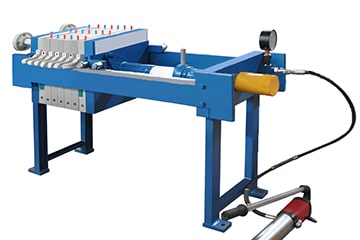

Automatic Filter Press

Fully automatic filter presses are designed for applications where continuous operation and rapid cycling are critical. Fully automatic filter presses offer a high degree of automation while providing uninterrupted operation. For example, the option to open the filter plate system simultaneously helps to achieve particularly fast cake release, thereby minimizing cycle times. The result is a high-speed filter press that increases the throughput per unit of filter area. For this reason, these machines are used for high filtration product applications that require high filtration speeds. These include, for example, mining concentrates and residues.

The automatic filter press and pump system control panel gradually increases the pump pressure of the standard unit to 105 PSI. this allows for uniform filling of the filter chamber and consistent cake quality. This system frees up the filter press operator’s time to perform other tasks.

Description

All automatic filter presses are controlled through an electro-hydraulic system, providing longer life and lower operating costs than the hydraulic components commonly found on filter presses. Controls can be customized to provide full automation for your existing water treatment facility.

The automatic filter press and pump control system works in conjunction with a pneumatic diaphragm pump to automatically increase feed pump pressure at predetermined intervals during the filter press fill cycle.

Features

- Highly automated while operating trouble-free

- Allows remote monitoring and operation

- Significantly reduces labor and maintenance

- Lower maintenance costs and higher performance

- Particularly suitable for highly filtered products with high filtration speeds

- Simple and economical filtration due to highest degree of dewatering and short cycle times