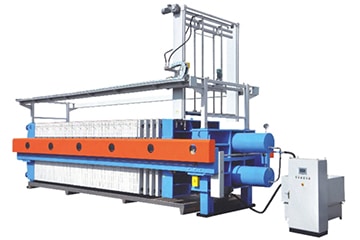

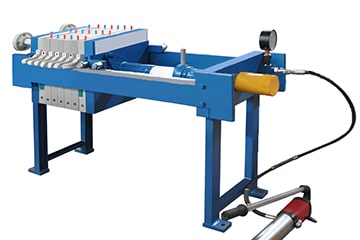

Chamber Filter Press

Chamber filter presses offer the advantages of simple design, low price, versatility, stability and durability. In the structure with box-type filter plates, filtration occurs in the space formed between two adjacent plates, and the volume of the filter press depends on the depth of the chamber. The chamber plates are generally made of high-strength polypropylene and offer high performance. The type of suspension to be filtered (e.g. mining, chemical or pharmaceutical industries) is irrelevant. Ideally suited for the filtration of sewage sludge, neutralized electroplating waste and ceramic slurries.

How does a chamber filter press press work?

At the beginning of the filtration cycle, the filter press and the filter plates are closed by the (hydraulic) locking cylinder. The closing cylinder presses the filter plates against each other by means of a pressure plate and accordingly increases the hydraulic pressure to the required nominal closing pressure. Due to this design, a chamber is formed between the individual filter plates, which represents the treatment chamber. The suspension to be filtered is pumped into the chamber with a suitable feed pump via the turbidity inlet of the feed table and concentrated there.

The clarified liquid after filtration (filtrate) is discharged along the channel system into a laterally mounted filtrate channel or, optionally, a closed filtrate outlet. On the other hand, the solid material remains in the plate chamber as a solid filter cake. The increased feed pressure compresses and dewater the filter cake produced in the chamber. The filtration process is complete once the throughput has dropped to a predetermined minimum, the pressure has increased significantly and the chambers within the filter plate are completely filled with cake. To empty the chambers, the shut-off pressure of the filter press is released, the filter press is opened and the cake is removed from the filter cloth. The filtration cycle is then repeated.

Advantages

- Highly configurable and maximum flexibility

- Compact and robust design for perfect and reliable filter operation

- High level of safety through the use of the latest safety technology

- Good price/performance ratio