What is activated sludge?

Activated sludge is a general term for the microbial community and the organic and inorganic substances on which they are attached. Activated sludge can be divided into aerobic activated sludge and anaerobic granular activated sludge, which is mainly used to treat wastewater, such as biofloc cultures formed in aeration tanks. Activated sludge method is a type of aerobic treatment method that uses suspended growth of microbial flocs to treat organic wastewater.

Activated sludge process

Activated sludge process is an aerobic biological treatment of wastewater and is widely used in municipal and industrial wastewater treatment. It removes dissolved and colloidal biochemical organic matter from wastewater as well as suspended solids and some other substances that can be adsorbed by activated sludge, and also removes a portion of phosphorus and nitrogen, and is a collective name for various methods of biological treatment of wastewater with microorganisms suspended in water.

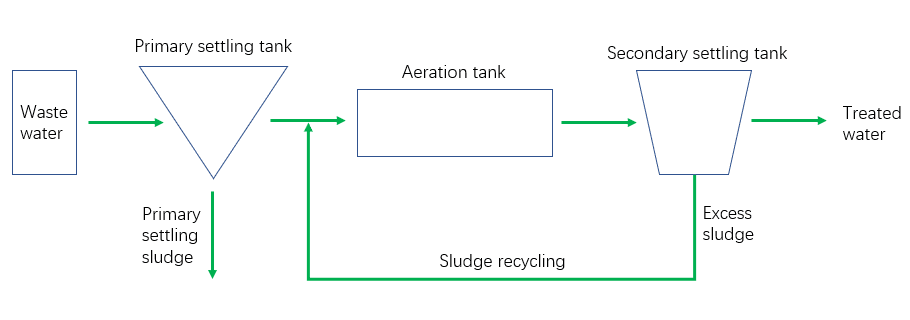

The activated sludge process (ASP) has three main components: an aeration tank used as a bioreactor; a settling tank to separate AS solids from the treated wastewater; and a return activated sludge (RAS) plant to transfer the settled AS from the clarifier to the influent of the aeration tank.

Due to the biological processes in the aeration tank, the concentrations of biodegradable components in the influent water of the activated sludge plant are reduced. Different boundary conditions, such as the hydraulic retention time (HRT) in the aeration tank, defined as the volume of the aeration tank divided by the flow rate, control the removal efficiency.

The activated sludge process in wastewater treatment involves air or oxygen being blown into the untreated wastewater. The wastewater is mixed and aerated in a special tank. This step in the process is achieved by pumping air or oxygen into an activated sludge tank or by using an aeration unit. The process oxidizes the organic matter in the wastewater, producing new cells, carbon dioxide and water. Sludge particles can then be removed by a gravity settling process.

Process solutions

- Effluent addition mode

- Sludge return to aeration tank mode

- Aeration mode

Sludge can be returned to the aeration tank either directly from the settling tank or through the sludge reaeration tank. Aeration can be uniform or variable from the head of the aeration tank to the end of the tank.

How does the activated sludge process work?

The activated sludge process in wastewater treatment involves blowing oxygen or air into untreated, unsettled wastewater. This process crushes the solids. The effluent is bubbled and the effluent is discharged into an activated sludge chamber. The live bacteria sink to the bottom of the chamber and the dead bacteria float to the top. As the live bacteria return to the digestion chamber, the clean water is discharged into a percolation tank or waterway.

Advantages of the activated sludge treatment process

- Reduces the amount of unwanted sludge.

- Wastewater treatment plants are reseeded with beneficial bacteria.

- The activated sludge treatment process allows for longer emptying intervals.

- The process is simpler.

- Costs are reduced.

Disadvantages of the activated sludge treatment process

- High initial cost.

- Specialists are required to design and build the activated sludge system.

- Skilled personnel are required to operate and maintain the activated sludge treatment.

- Continuous use of electricity increases energy consumption for wastewater treatment.

- Sludge and effluent may require further treatment or proper discharge.

Types of activated sludge plants

There are several types of activated sludge plants. These include:

Package plants

There are several types of packaging plants that typically serve small community or industrial plants that may use mixed treatment processes that typically involve the use of aerobic sludge to treat incoming wastewater. In such plants, the primary settling stage of treatment may be omitted. In these plants, bioflocs are produced that provide the required substrate.

Oxidation ditches

In some areas with more available land, wastewater is treated in large circular or elliptical trenches with one or more horizontal aerators often called brush aerators or disc aerators, which drive the mixture around the trench and provide aeration.

Surface aeration basin

Most biological oxidation processes used to treat industrial wastewater use oxygen (or air) and microbial action. Surface aeration basins can achieve 80% to 90% BOD removal. In an aeration basin system, aerators provide two functions: they deliver air to the basin required for the biological oxidation reaction, and they provide the mixing required to disperse the air and contact the reactants.

Sequencing batch reactor (SBR)

A sequencing batch reactor (SBR) treats wastewater in batches in the same vessel. This means that the bioreactors and the final clarifiers are not spatially separated, but are arranged in a chronological order. The unit consists of at least two identically equipped tanks that have a common inlet and can be used alternately between them.