Ozone Generator

Ozone generators are designed for laboratory and research in water, medical, chemical and industrial research and wastewater treatment facilities. It can be used in chemical research for ozonolysis, where ozone oxidizes olefins to form alcohols. In wastewater treatment, ozone is a powerful oxidizer that reduces the chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of organic material.

The unit is housed in a rugged stainless steel cabinet and all components in contact with oxygen and ozone are made of stainless steel, glass or PTFE tubing.

The industrial ozone generator system uses a water-cooled corona discharge (CD) tube to generate ozone from various pressurized sources such as compressed air, bottled oxygen or oxygen generators. The result is a high ozone concentration with low energy requirements.

What is ozone?

Ozone (O3) is a molecule made up of three oxygen atoms. Two oxygen atoms form the basic oxygen molecule – the oxygen that living things breathe. The third oxygen atom can be separated from the ozone molecule and reattached to molecules of other substances, thus changing their chemical composition. Ozone is an unstable chemical that is highly reactive with other gases in the air. Ground-level ozone is unhealthy and is a component of smog. Ozone found high in the atmosphere, called stratospheric ozone, protects us by protecting us from harmful ultraviolet (UV) rays.

Industrial ozone generator water treatment systems

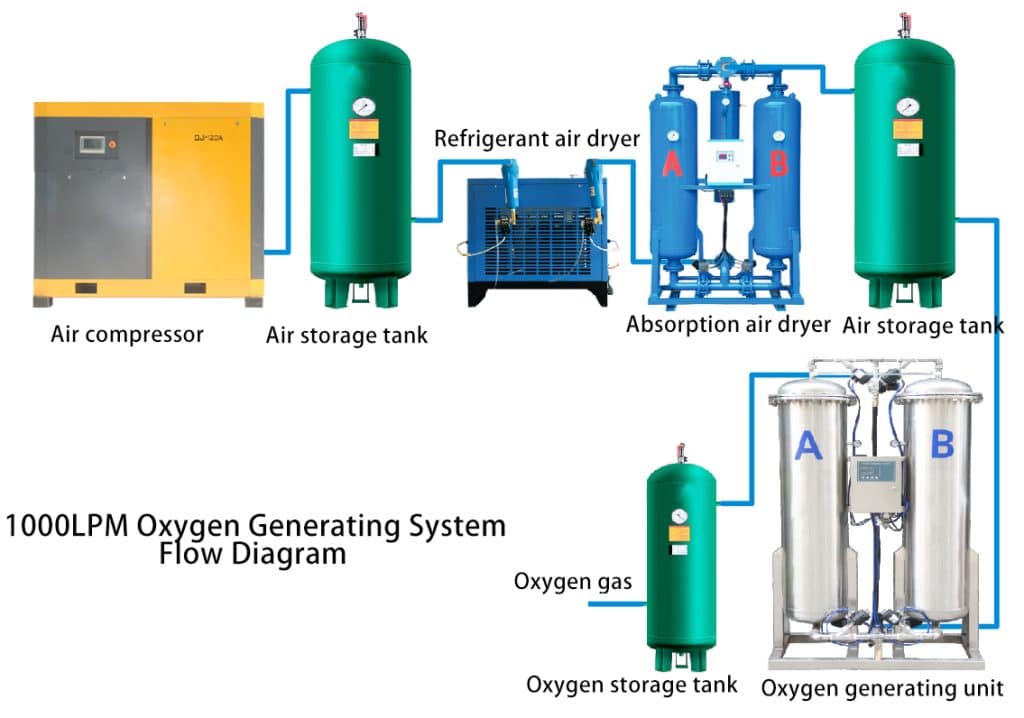

KUOSI ozone generator system includes compressor,air tank,air dryer,air cooler oxygen generator,ozone generator,cooling water system, venturi-injection system(including booster pump). The system is built according to customer requirements and a standard system is shown in the following diagram.

Features

- The use of imported high-efficiency anti-quartz medium, 316L stainless steel inner pole, long service life, high efficiency and energy saving, the same power consumption, high ozone output.

- Digital module power supply, large load, stable voltage output, to ensure the efficient and stable operation of equipment;

- Built-in air source processing system, filtering, compression, drying, to ensure that the air into the discharge chamber dry clean, improve discharge efficiency, prolong the service life of equipment;

- Microcomputer time control, users can according to the actual use of their own design equipment running stop time, can set up a maximum of 16 groups of different switching program;

- High-power fan cooling, cooling effect is good, users do not need to install their own cooling water trouble, easy to operate and use;

- The shell is made of stainless steel, beautiful and generous, corrosion resistant.

Applications

Air purify

- Food processing plant

- Cosmetic plant

- Refrigerator

- File room

- Pharmaceutical factory

- Poultry

- Schools

- Hotel

- Hospitals

- Restaurants

Water treatment

- Mineral water

- Bottled water

- Pure water

- Swimming pool

- Aquaculture

- Farm feeding water

- Beverage plant

- Industrial wastewater

- Cooling tower system