Filter Press

The filter press is a solid-liquid separation equipment that uses a special filter medium to apply a certain pressure to the object, making the liquid percolate out. The slurry is pumped into the filter press and dewatered under pressure. It is used for water and wastewater treatment in a variety of different applications from industrial to municipal.

Filter Press Catalogues

How does the filter press work?

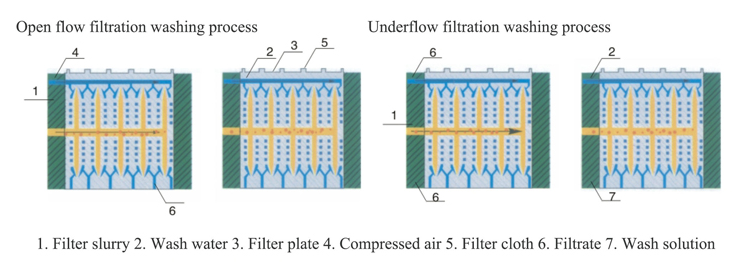

During work, the compaction device(cylinder piston rod or screw) pushes the com-paction plate to compact the filter plate and filter cloth located between the compaction plate and the thrust plate. A filter chamber is formed between compacted filter plate and filter plate. The material pressed by the feed pump enters each filter chamber through the feed hole of the thrust plate. The solid particles are trapped in the filter chamber and form a filter cake. The liquid passes through the filter cake and the filter cloth.Liquid holes are discharged from the body. If you need to wash the filter cake, you can wash the filter cake with washing water through the washing liquid port on the tail plate. If it is necessary to blow dry the filter cake, blow compressed air through the washing liquid port to blow dry the filter cake.

- Filter slurry

- Wash water

- Filter plate

- Compressed air

- Filter cloth

- Filtrate

- Wash solution

The liquid flow form of the filter press is divided into open flow and dark flow. Open flow means that the filtrate is directly discharged from the liquid outlet of each filter plate, dark flow means that the filtrate from the filter plate is combined and discharged from the machine through the liquid outlet channel.

Structure of the filter press

- Frame (skeleton): The steel filter press frame serves as the clamping device for the filter plates.

- Filter plates: Filter plates are divided into three basic categories, all with different functions. Plate frames, concave chambers (or concave plates) and diaphragm extrusions (also called membrane extrusions).

- Manifolds: Our standard manifolds consist of pipes and valves. They control the slurry inlet and connect the four corner filtrate discharge ports to a common discharge pipe.

- Filter cloth: The filter cloth attached to the filter plate. Solids accumulate on the cloth to form a filter cake that separates the liquid from the solids.

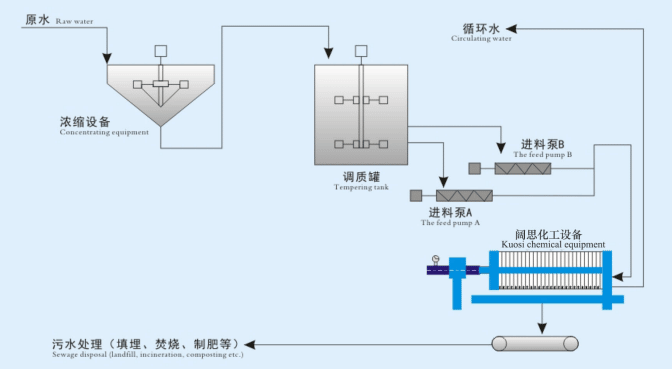

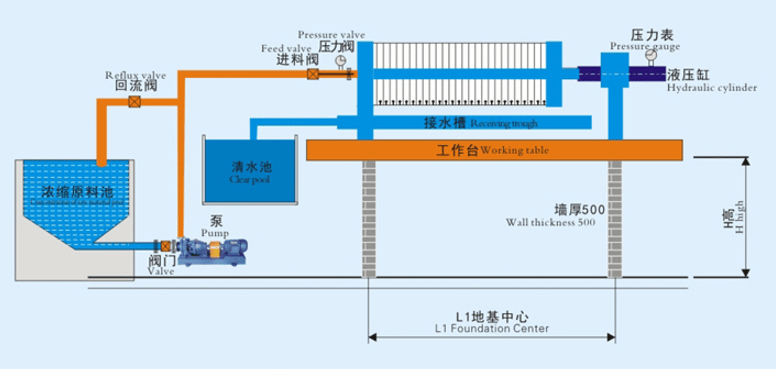

Filter press diagram

Industry applications

Filter presses can be used in a variety of dewatering applications, including but not limited to:

- Food and beverage processing

- Chemical manufacturing

- Mining

- Power generation

- Steel plants

- Municipal water treatment

- Manufacturing

- Wastewater treatment

- Concrete/cement production

- Electroplating industry

Why choose KUOSI filter press machine?

Choosing the most suitable filter press requires consideration of industry, application and operation, such as overall design, filtration capacity, number of chambers, filter plate size, and other features such as automatic plate change, filter cloth cleaning system, and safety light curtains. The design of a filter press depends on a range of factors such as filtration cycle time, desired cake dryness, filter cloth life, and whether manual or automatic plate removal is required.

KUOSI is a manufacturer and supplier of filter presses in China, wholesaling all kinds of industrial sludge filter press equipment and accessories. Our team of filtration professionals will help you achieve your production goals by providing engineered filtration solutions that fit your industry’s applications and operating conditions. We offer a wide range of filter press sizes and options for your industry and application.