Paddle Dryer

Paddle dryers are highly efficient, mechanically stirred, indirect heat transfer devices that add or remove heat from process materials. The required heat transfer is achieved by heating or cooling the shaft and the dryer body. In addition to the very good indirect heat transfer, the space requirements are low due to its compact design. The intermeshing motion of the paddles ensures uniform and constant mixing of the material in continuous or batch operation. The heat transfer media: steam, oil, hot fluids and water.

Mainly used for indirect drying, heating, cooling, pasteurization, crystallization and reaction of pastes, cakes, powders, organic or inorganic particles. Hollow paddle dryer is often used for sludge drying in wastewater treatment.

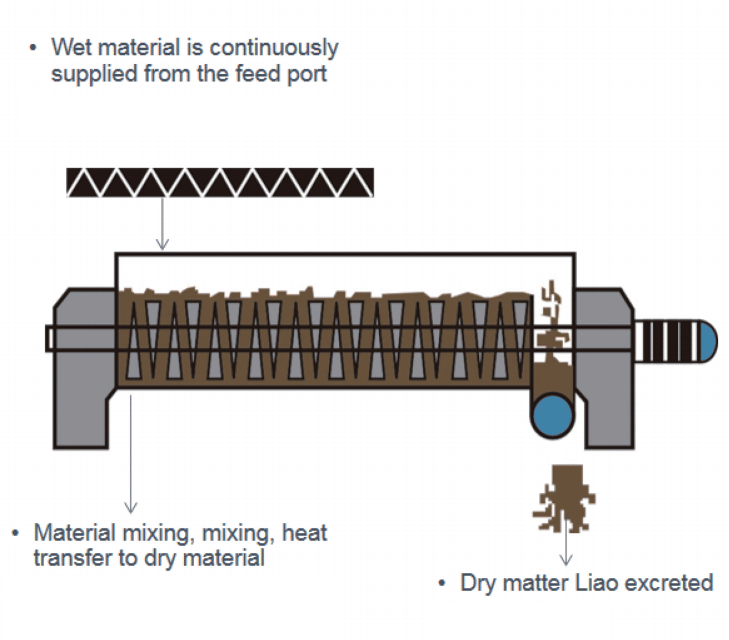

Paddle dryer working principle

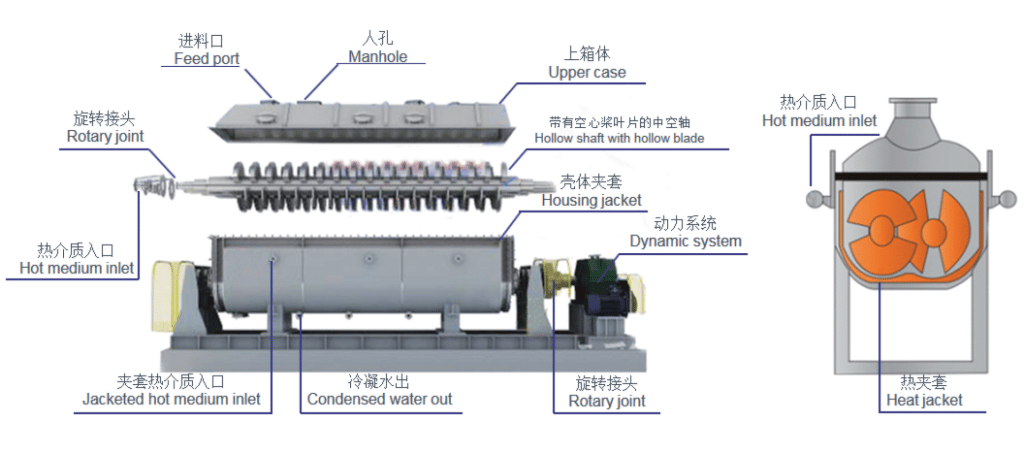

The hollow shaft is densely arranged with wedge-shaped hollow slurry leaves, and the hot medium flows through the slurry leaves via the hollow shaft. The heat transfer area is large within the unit effective volume, and the temperature of the hot medium is from -40℃ to 320℃, which can be water vapor or liquid such as hot water, heat-conducting oil, etc. Indirect conduction heating, no carrying air to take away heat, heat are used to heat the material. The heat loss is only the heat dissipation to the environment through the insulation layer of the body. Wedge type slurry leaf heat transfer surface has self-cleaning function. The relative movement of the material particles and the wedge-shaped surface produces a scrubbing effect, which can scrub off the material attached to the wedge-shaped surface and keep a clean heat transfer surface during operation. The heat transfer medium flows through the shell jacket and hollow stirring shaft through the rotary joint, and the hollow stirring shaft has different internal structure according to the type of heat medium to ensure the heat transfer effect.

Hollow paddle dryer structure

Features

- High thermal efficiency

- The heat transfer medium does not come into contact with the product

- Gas is not used to transport the product. Minimal exhaust gas flow

- Suitable for steam, water or oil as heating medium

- Precise temperature control

- Homogeneous product quality, full product mixing and movement

- Continuous process in a single pass

- High heat transfer area to process volume ratio – reduced footprint

- Usually no pretreatment with recirculation required

- Easy to operate, requiring little attention

- Safer than direct drying when handling combustible materials

- Simple and durable design for easy maintenance

- Low product wear and tear

- Reduced civil construction and installation costs

- Suitable for all types of particles and free-flowing materials

Applications

Drying

Paddle dryers are indirectly heated using steam or circulating thermal fluid (thermal oil). This provides high energy efficiency and low exhaust gas volumes. Heat transfer media of up to 750 °F can be used. Provides a reliable and efficient method for drying slurries, cakes and centrifugal concentrates. The vacuum design allows for the removal of water or organic solvents at reduced temperatures.

Heating

Heating is used to melt, cook, pasteurize, bake or react process materials. The heating medium can be steam, circulating hot fluid or hot water. The dual zone design allows for two different temperature zones.

Cooling

Heat is removed from the process material with cold water or heat transfer fluid (glycol, down to -40 °F). Cooling can be performed in a controlled, moisture-free environment. The dual-zone design allows for two different temperature zones.

Calcination

Calcination can be performed at temperatures up to 700 °F. Evaporation of water prior to high temperature calcination will increase the capacity of the high temperature equipment and the thermal efficiency of the process.

Reaction

Use the paddle dryer to catalyze and control reactions, taking advantage of our ability to accurately temperature and residence time. It can be used for both exothermic and heat-absorbing reactions. The high degree of mixing as part of the reaction process allows for thorough mixing of multiple components.

Crystallization

Use the paddle processor for selective polymer crystallization or crystallization at controlled rates and temperatures.

Materials processed include

- Chemical: salts, catalysts, brominated organics, cellulose, starch

- Petrochemical: solids de-volatilization fractions

- Polymers and plastics: polypropylene, polycarbonate, polyphenylene sulfide, PET, PTA

- Food: flour, beverage powder, candy ingredients, meat products, biomass, hemp, etc.

- Minerals and metals: metal powders, metal carbonates, sulfates and hydroxides

KUOSI is a manufacturer and supplier of paddle dryer in China, offering Hollow blade paddle dryer with good price and quality. Welcome to contact us for quotation.