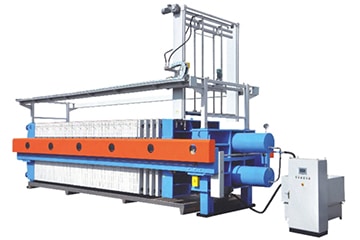

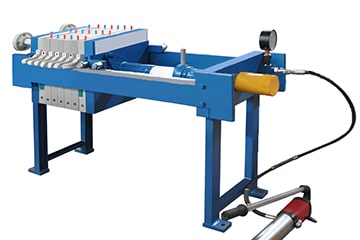

Membrane Filter Press

The membrane filter press has a significant impact on the dryness of the solids through the use of membrane technology in the filter plate. It achieves the lowest residual moisture values in the filter cake compared to conventional filtration processes. The shortened filtration cycle time, efficient washing and drying of the sediment without unloading the sediment from the filter, results in a low water content sludge.

The filtration process of a membrane filter press is similar to that of a chamber filter. The fundamental difference, however, is that when filling the chamber with sediment, it is not unloaded immediately, but is squeezed by the action of the fluid supplied under the membrane. The possibility of squeezing occurs due to membrane plates. Mechanical squeezing of the sediment using the filter membrane significantly reduces the time of one cycle and improves the daily performance of the filter press.

How does a membrane filter press press work?

The membrane filter press is fitted with an elastic membrane between the filter plate and the filter cloth. When in use, the feed is completed and a high-pressure fluid or gaseous media can be injected into the diaphragm plate. At this point, the entire membrane will bulge and squeeze the filter cake to achieve further dewatering of the cake, which is usually called squeeze filtration.

Membrane filter presses are fed in the same way as chamber filter presses, but the filling level of the chamber can be manually controlled. The increased feed pressure ensures pre-compression and dewatering of the filter cake in the chamber. Once the feed pressure reaches a predetermined value, the filter cake is squeezed again accordingly. The flexible membrane presses the filter cake solids onto the entire surface of the chamber. The compression and consequently the discharge of free water from the filter cloth.

To achieve higher filtration quality, some effective configuration options are available including cake washing, cake dry blowing and core flushing.

Advantages

- High pressing pressure

- Corrosion resistance

- Easy maintenance

- Safe and reliable