Sludge Dewatering Machine

In the process of wastewater treatment, water-content sludge of different nature is generated. The main purpose of sludge dewatering equipment is to reduce the water content of sludge and reduce the volume of sludge, thus facilitating the subsequent treatment or disposal of sludge. Its compact structure and low energy consumption are increasingly accepted by wastewater treatment contractors. Choosing a better quality and reasonably priced sludge dewatering machine will bring the user a good profit.

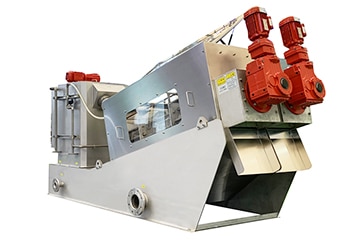

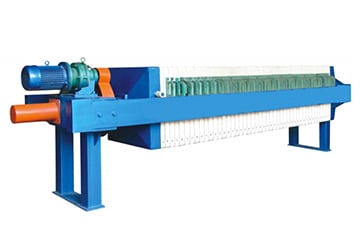

In the wastewater treatment industry, the commonly used dewatering equipment can generally be divided into filter presses, decanter centrifuges and screw presses. The operation of filter presses is more demanding, and a large amount of water is required to flush the filter cloth, but the discharged mud cake is relatively dry. When the labor cost is high, the site is limited, and the solid content of the material is high, a dewatering decanter centrifuge can be used as the ideal equipment. Screw press sludge dewatering machine, also known as multi-disc dewatering machine, has the advantages of energy saving, stability and high degree of automation. It is widely used in municipal wastewater treatment projects and water treatment systems in the food, petroleum, pharmaceutical, chemical, paper, leather and other industries.

Sludge dewatering is the process of separating solid and liquid sludge components to minimize sludge disposal. Often polymer flocculants are also added prior to sludge dewatering (using powder dosing system) to help the solid-liquid separation process.

Instead of treating sludge or liquids, the sludge dewatering facility will separate liquid and solid components, making it easier and cost effective to treat the different treatment stages. After final sludge dewatering, the liquid is treated in ETP/STP and the solid sludge is disposed of.

The main purpose of sludge dehydrators is to minimize treatment and disposal. Sludge dehydrators are the most cost-effective method of dehydration and therefore help to maintain the company’s environmental objectives.

KUOSI is a manufacturer and supplier of sludge dewatering equipment and systems. Mainly offering filter presses and screw press machines, contact us to select or customize the most suitable sludge dewatering machine for your application.