Sludge Dewatering

What is sludge dewatering?

Sludge dewatering separates sludge into liquids and solids, minimizing the volume of waste and making it easier and more cost effective for final disposal. Sludge is a semi-solid slurry that is produced from various industrial and municipal water treatment processes. Dewatering sludge with sludge dewatering equipment can significantly reduce its weight and volume prior to disposal.

How does the sludge dewatering process work?

Before the dewatering process begins, the sludge must be passed through any of the mineral chemicals or organic chemicals, such as coagulants and flocculants. After conditioning the sludge, it is then thickened by dissolved air flotation, gravity belt, thickening drum/spiral drum or centrifuge.

Once the conditioning step is complete, the analysis of the most suitable sludge dewatering technology can begin. The choice of sludge treatment method depends on several factors, including characteristics, volume, time and disposal options available. Common dewatering options are plate and frame filter presses, membrane filter presses, chamber filter presses, belt filter presses, centrifuges and screw presses.

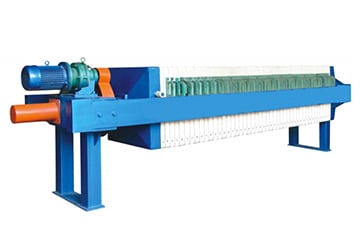

Filter Press

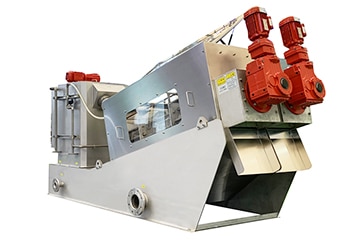

Screw Press

Benefits of sludge dewatering

Waste volume reduction

The focus of sludge dewatering is to reduce weight and volume in order to minimize waste disposal costs. Therefore water removal is the primary means of volume reduction until the sludge by-products can be economically disposed of.

Reduce transportation costs

A dry, high solids content cake means lower costs. The use of dewatering equipment is an effective tool for managing sludge accumulation and can reduce transportation costs and storage costs.

Wastewater recycling

Once the sludge is dewatered and treated water is free of hazards and contaminants, it can be recycled by industry and communities for reuse. For example, steam power plants use reclaimed water to provide power services to communities.

Automation

Many people think of filter presses as labor-intensive equipment. In fact sludge dewatering filter presses can be automated with automatic cloth washers, mechanically assisted cake release devices and sophisticated control systems that allow communication with the main plant control system.

Protecting the environment

Reduces the volume of waste to a more compact and manageable size for disposal. While the dry cake is disposed of, the reuse of the filtrate reduces the need for new water sources required for treatment in municipal and industrial wastewater plants, as well as the overall amount of water required for treatment.