Forms of Wastewater Solids

Wastewater solids come in many forms. Solid pollutants in the water body mainly in the form of suspended matter, colloidal matter and dissolved solids exist.

- Suspended matter: impurities with particle size up to 100nm in water, generally in suspension, often lead to turbid water quality. It mainly includes inorganic sediment, organic algae, microorganisms and microbial sludge.

- Colloid: particle size of 1 ~ 10nm, gel-like. Usually composed of inorganic colloid and polymer organic colloid.

- Dissolved solids: impurities with particle size less than 1nm, mainly some low molecular compounds, dissolve in water without affecting the transparency.

Different types of wastewater solids in water treatment have their own characteristics and targeted treatment methods. Some conventional data on solids pollutants are listed below.

Sludge volume

Sizing sludge treatment units and equipment (e.g. sludge pumps, tanks, thickeners, digesters, filter presses or screw presses and incinerators) requires determining the amount of sludge generated during the wastewater treatment process. Typically, the solids generation rate for treated wastewater ranges from 0.2 to 0.4 kg/m3.

Field

The screen includes relatively large debris such as rags, plastics, cans, branches, etc. Screening volumes vary from 5 to 50 mL/m3 of wastewater. Screened residue is typically transported to landfills.

Grit

Gravel consists of heavy and coarse materials, such as sand and cinder. It also contains organic materials, e.g. corn, seeds. Grit can wear out pump impellers and pipes if not removed from the wastewater. Grit is usually removed in grit settling tanks. In some treatment plants, the grit settles with the primary sludge in a primary clarifier and is then separated from the sludge in a grit separator. The amount of grit removed varies from 3 to 210 mL/m3 of wastewater.

Scum

Scum is the product of skimming from the clarifier. Primary scum consists of fats, oils, greases and floating materials such as plastics and rubber products. Secondary scum tends to be primarily floating activated sludge or biofilm, depending on the type of secondary treatment used. In some cases, dissolved air flotation systems are used instead of clarifiers.

Primary sludge

In water treatment plants with primary settling and conventional activated sludge secondary treatment processes, the dry weight of primary sludge solids is approximately 45% of the total sludge solids. The total solids concentration in raw primary sludge can vary between 3% and 8%. Compared to biological and chemical sludge, primary sludge can be dewatered quickly and will produce a drier cake and provide better solids capture with lower conditioning (added polymer) requirements.

Primary sludge solids yield typically varies between 0.2 and 0.4 kg/m3 of wastewater. The most common method for estimating primary sludge production is to calculate the amount of suspended solids entering the treatment plant and assume a removal rate. Removal rates typically range from 45% to 65%.

A typical BOD removal rate is 45% of the suspended solids removed.

Secondary sludge

Secondary sludge, also known as biological sludge, is produced by biological treatment processes such as activated sludge, membrane bioreactors, trickling filter tanks, and rotating biological contactors. Plants using primary sedimentation typically produce a fairly pure biological sludge as bacteria consume soluble and insoluble organic matter from the secondary treatment system. Activated sludge and trickling sludge typically contain 0.3% to 1.4% and 1.5% to 4.5% solids concentration by weight of dry solids.

Secondary sludge is the biomass produced by secondary treatment processes such as activated sludge and its many variants such as extended aeration, oxidation ditches, piston flow, step feed, sequencing batch reactors (SBR) and membrane bioreactors (MBR). Secondary sludge also includes non-biodegradable inorganic particulate matter that is not removed by primary settling. Since the amount of organic loading during secondary treatment is the most important factor in biosolids production, the removal rate of biological or chemical oxygen demand (BOD or COD) from primary settling is very important.

Chemical sludge

Chemicals are widely used in wastewater treatment, especially in industrial wastewater treatment, to precipitate and remove difficult to remove materials and, in some cases, to improve the removal of suspended solids. In all these cases, chemical sludge is formed. A typical use for removing substances from wastewater is the chemical precipitation of phosphorus. Chemicals used for phosphorus removal include lime, alum and “pickling solutions” such as ferrous chloride, ferric chloride, ferrous sulfate and ferric sulfate.

Summary

Wastewater contains various solid materials that require effective removal for proper treatment. These solids include suspended solids, colloids, and dissolved solids, each differing in size and composition. Managing sludge volume is essential for designing treatment systems, as different types of solids contribute to sludge generation.

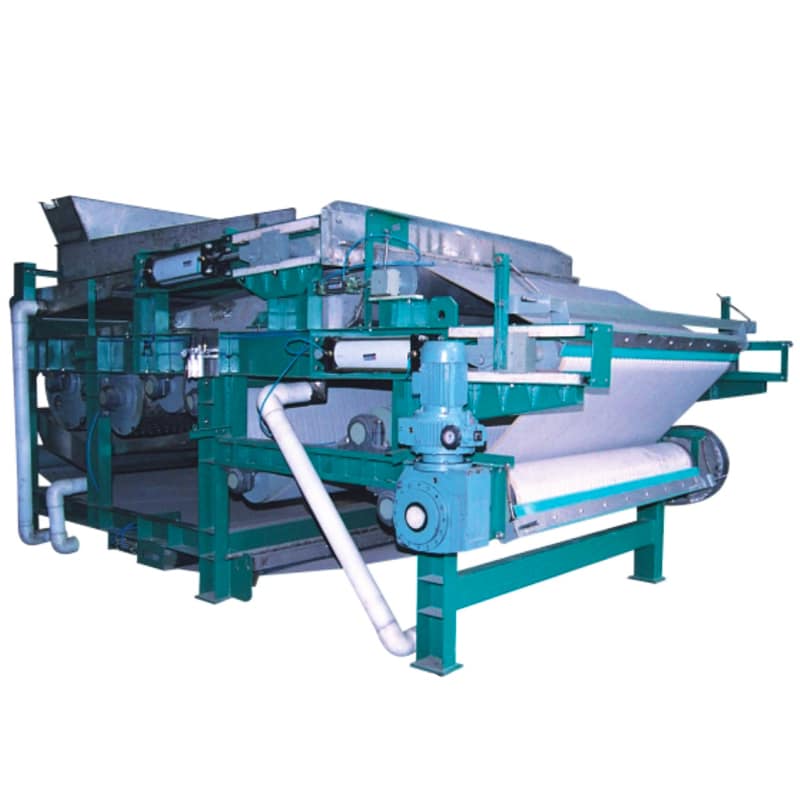

KUOSI offers sludge dewatering machines, sludge dryers, sludge conveyors, dosing systems, aeration blowers, disinfection systems, wastewater screens, scrapers, and grit removal equipment. Please contact us for further information.