What is industrial waste water?

Industrial waste water includes produced wastewater, produced effluent, and cooling water, and refers to wastewater and waste streams generated from industrial processes that contain industrial production materials, intermediate products, byproducts, and pollutants generated during the production process that are lost with the water. Industrial wastewater has a wide variety and complex composition, which often contains a variety of toxic substances, polluting the environment and posing obvious hazards to human health. Therefore, according to the composition and concentration of pollutants in wastewater, corresponding purification measures should be taken for disposal before discharge or reuse.

Industrial wastewater from different industries

Steel

Iron and steel production in the output of iron workshop waste water, steel workshop waste water and rolling workshop waste water. Steel wastewater treatment is mainly to improve the reuse of water resources. In the pollution sources of iron and steel wastewater treatment, the emphasis is on coking phenolic wastewater, blast furnace gas washing water and top blown converter washing water.

Paper making

Including pulping and cooking waste liquid, washing wastewater, bleaching wastewater and paper machine white water. The main problem to be solved in papermaking wastewater treatment is to remove SS and COD. There are mainly the following methods

- Dissolved gas flotation. By adding coagulant, most of SS, most of non-dissolved COD and part of dissolved COD and BOD5 can be removed.

- Combination of physicochemical and biochemical treatment. Soluble COD and BOD5 can be effectively removed mainly by biochemical methods.

- Sludge disposal and comprehensive utilization. The loss of pulp is inevitable in the process of papermaking. There are two advantages to recycling the waste pulp into the wastewater: first, the recycled pulp can be used for papermaking or sold as raw materials of low-grade paper, resulting in direct economic benefits; The second is to reduce the waste water treatment load, reduce the consumption of pharmaceutical.

Petrochemical

The content of organics, especially hydrocarbons and their derivatives in petrochemical wastewater is high, and contains many heavy metals. The oily wastewater is a kind of wastewater with the largest displacement in the process of refining, processing, storage and transportation, which mainly contains crude oil, refined oil, lubricating oil and a small amount of organic solvents and catalysts. The oil in water mainly exists in the state of floating oil, dispersed oil, emulsified oil and dissolved oil in waste water. The oil is often separated by dissolved air flotation technology in the pretreatment stage, and the sludge is dehydrated and desiccated later, so as to achieve effective treatment.

Metal pickling

In order to remove metal surface oxides, sulfuric acid, nitric acid, hydrochloric acid, hydrofluoric acid and phosphoric acid are used to treat the wastewater produced by pickling. The processing technology mainly includes neutralization method, ferric sulfate method, organic solution extraction method, dialysis method, ion exchange method and so on.

Chemical fertilizer

Pollutants in fertilizer industry sewage are ammonia nitrogen, sulfide and total cyanide. Mainly contains organic matter, alcohol, ammonia, nitrate, phosphorus, cadmium and other heavy metals and suspended matter. The nature of outflow logistics varies in its composition and complexity. The water is high in ammonia nitrogen and contains toxic total cyanide and sulfides.

Textile printing and dyeing

It mainly contains dirt, grease, salt on textile fiber and all kinds of paste, dye, surfactants, auxiliaries, acid and alkali in the process of processing.

To treat by anaerobic hydrolysis. The synthesis of dye is a kind of refractory organic matter, the hydrolysis acidification process, can buffer, to reduce the pH of raw sewage, COD removal efficiency of subsequent aerobic treatment, prevention and overcoming the follow-up activated sludge process may occur in the process of handling or filamentous sludge bulking bacterium excessive growth, enhance treatment system running stability and reliability.

Power station

Waste water produced by coal, oil, combustible gas and other power generation processes in thermal power plants. There are mainly ash water, dust water, industrial sewage, domestic sewage, acid and alkali waste liquid, condenser cooling water drainage and so on. Dust removal water and industrial sewage are generally discharged into the grey water system. Acid and alkali waste liquid mainly comes from boiler water supply system, waste acid liquid is generally discharged into the neutralization pool and then discharged. Direct discharge of condenser cooling water will cause thermal pollution. It will affect the reproduction and growth of aquatic organisms.

Semiconductor

Semiconductor manufacturing involves a wide and complex range of slags and chemicals, requiring rigorous solid-liquid separation, treatment and recovery systems. Semiconductor wastewater mainly includes acid and alkali wastewater, fluoride wastewater and grinding wastewater. The treatment process is as follows

- Acid and alkali wastewater treatment process

The acid-base wastewater enters the acid-base wastewater control tank for aeration and mixing, and then enters the pH neutralization tank through the water pump for three-stage acid-base dosing reaction. Adjust the pH to neutral, the effluent into the discharge pool, discharge standard.

- Fluorinated wastewater treatment process

The fluorinated wastewater enters the fluorinated regulating tank for aeration and mixing. After lifting pump to fluorinated reaction tank. A pH meter is set in the pool to control the dosage pump to add acid and base, adjust the pH value to be 7-9, and CaCl2 is added at the same time to generate precipitation. Then it flowed into the coagulation tank and flocculation tank in turn. PAC and PAM were added through dosing pump to further coagulate and precipitate.

- Grinding wastewater treatment process

The grinding wastewater enters the grinding wastewater regulation tank, and after aeration and mixing, it is lifted to the reaction tank by the water pump. The pH is adjusted in the tank and PAC is added for coagulation and precipitation, and then it flows into the flocculation tank. PAM is added to the tank, and the flocculation is entered into the sedimentation tank. The sedimentation tank supernatant then enters the biochemical tank.

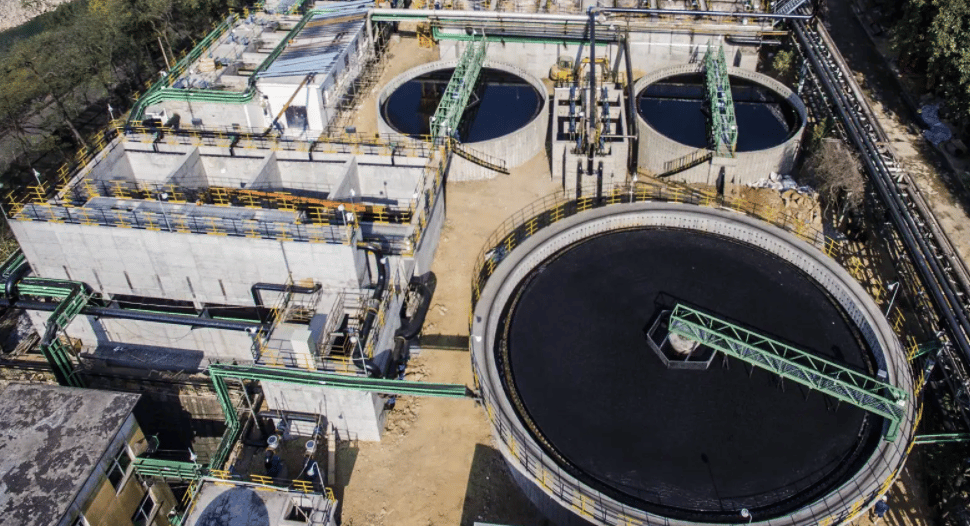

How to treat industrial wastewater?

As mentioned above, different industries produce widely varying and different wastewaters, and their treatment processes and the water treatment processes employed vary greatly. Grates and screens are usually located at the very front of the treatment and are used to filter medium to large volumes. And then a roots blower is used for aeration. Sludge is usually produced in industrial wastewater treatment, and the sewage sludge is first dewatered and depending on the situation may require further drying (often using a paddle dryer). In the case of domestic wastewater, disinfection equipment is usually used at the end to sterilize the water.

In summary, different industries have their own most suitable water treatment solutions for different types of industrial wastewater, so feel free to contact us to inquire about the right solution or equipment for your application.