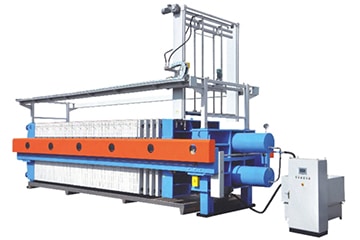

Mobile Filter Press

Mobile trailer filter presses are self-contained mobile dewatering systems designed for the harsh conditions of various applications. The filter press is mounted on a special semi-trailer with all components, including a built-in conveyor belt for material handling, and is a completely self-contained mobile dewatering system. This system uses a sludge dewaterer to better respond to customer needs in a variety of solid-liquid separation applications.

Mobile filter presses can be ideal for dewatering slurries and managing sludge in remote areas and are common in the oil, gas and fracking industries.

Description

Sludge dewatering in municipal or industrial wastewater treatment is complex, not only in terms of sludge composition, but also in terms of the economic and technical boundary conditions of the plant which vary considerably. Only by analyzing the whole picture can an optimal solution be derived. Minimizing dewatering costs. Therefore, stationary filtration plants can only be used at low utilization rates. Therefore, cost-intensive investments are usually offset by a moderate capacity utilization.

The more specific the process technology equipment, the higher the associated investment costs. Especially in industrial wastewater treatment plants, this fact inevitably leads to a situation of economic conflict. Efficient and technically superior dewatering systems (e.g. filter presses) are characterized by relatively high investment costs and low equipment utilization. With the exception of semi-mobile filter presses, mobile filter press equipment is the answer to the question of an economical and self-sufficient filtration method.

Mobile filter presses are fully equipped and can be put into operation immediately after connection of sludge, water and power. In this way, optimal results can be achieved for each task. It can also help you to plan and assemble your individual plant. In this respect, mobile filter presses are particularly suitable for dewatering sludge from multiple plants on a regular basis or for compensating capacity peaks and bottlenecks.

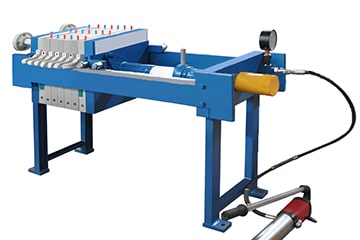

Mobile filter press plants are available in many different designs. Box filter presses or membrane filter presses are optional, and depending on the application, a suitable feed pump (pneumatic diaphragm pump) can also be selected. Mobile filter presses are delivered in semi-trailers or truck trailers. Conditioning of the sludge is mainly carried out using polyelectrolytic flocculants (Usually used to the preparation of polymer dosing system). Further methods are lime/iron conditioning and dosing of solid filter aids. Therefore, these units are equipped with in-line mixers on the suction and pressure side. PLC units control conditioning parameters proportional to pressure and/or volume.

Advantages

- Complete independent filtration system from feed pump to cake transfer

- Conveyor deck retracts under the press for transport

- Unit comes with compressor and complete control system

- Standard pump system is an air-operated diaphragm pump

- Includes standard walkways, safety rails and stairs