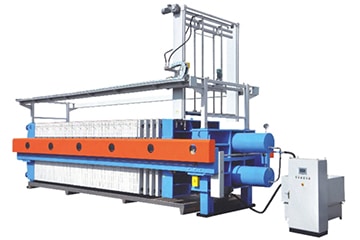

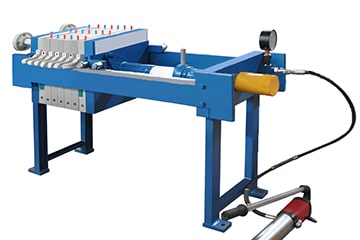

Cast Iron Filter Press

Cast iron filter presses are made of high quality cast iron or ductile iron. It is suitable for the filtration of high temperature materials. The filter plate has high strength, high filtration pressure and long service life. The core of the cast iron filter press consists of a series of horizontally designed chambers arranged in parallel. The chambers consist of stacks of flat plates, each carrying filter cloth or other suitable filter media. The plate stacks are typically compressed by handwheel, positive electro-mechanical or electro-hydraulic pressure, with the filter cloth acting as a spacer between the individual chambers.

Cast iron filter presses are ideal for dewatering applications and are widely used in oil refining, metallurgy, ceramic industries (kaolin, active bentonite, soil) and other industries requiring solid-liquid separation processes.

Features

- High capacity

- Corrosion resistant

- Low water content

- High efficiency

- Easy to use

Applications

- Food Industry

- Pharmaceutical industry

- Waste treatment

- Wastewater treatment

- Concentrate processing

- Industrial minerals

- Metallurgical processing

- Chemical processing