Sewage and sludge contain a large number of hazardous substances, which, if discharged directly without treatment, will have a serious impact on water resources, soil, air quality and biodiversity. Therefore, effective sewage and sludge treatment is essential. Incineration is an effective treatment method that can significantly reduce the volume of sludge, destroy harmful substances and recover energy, making it an important means of environmental protection and resource treatment.

Sewage Treatment and Equipment

The basic process of sewage treatment mainly includes pre-treatment, primary treatment, secondary treatment and tertiary treatment.

- Pre-treatment: large impurities in the raw sewage, such as twigs, leaves, paper, etc., are removed mainly by wastewater screen.

- Primary treatment: mainly using sedimentation tanks and air flotation to precipitate suspended solids in the sewage, and some organic and inorganic substances are also removed.

- Secondary treatment: mainly biological treatment stage, common biological treatment equipment including activated sludge method of bioreactor, oxidation ditch, filter beds, rotary table and so on. This stage is mainly the use of microorganisms and bacteria to convert organic substances into harmless substances.

- Tertiary treatment: also known as advanced treatment, mainly through a mixture of physical, chemical and biological processes to remove pollutants still present after secondary treatment, including phosphorus, nitrogen and other nutrients and toxic and hazardous substances.

The main objectives of disposal waste water are: to protect the water environment and prevent pollutants from entering the water body; to recycle valuable resources such as water, organic matter, phosphorus, nitrogen, etc.; and to reduce the toxicity of discharges to protect the ecosystem and human health.

Sludge Treatment Equipment

Sludge From Sewage Treatment

During wastewater treatment, a portion of the solid pollutants are separated out to form sludge that contains a large amount of water. For example, the wastewater treatment chemicals process may include chemical precipitation, where various chemical coagulants are added to cause tiny particles to coagulate into larger particles and settle out, forming a chemical sludge. Sludge from wastewater treatment contains a variety of organic and inorganic pollutants, which may include potentially harmful substances such as pathogens and heavy metals, and must be properly treated before it can be safely discharged or utilised.

How is sludge treatment performed?

Sludge treatment is a complex process whose main objectives are to reduce the volume of sludge, lower its water content, stabilise it as well as render it harmless for its final disposal or resource use.

- Thickening:The thickening stage is mainly based on physical methods (e.g. gravity settling) to reduce the water content of the sludge and thus increase its consistency. In this stage, commonly used equipment include gravity thickener and flotation machine.

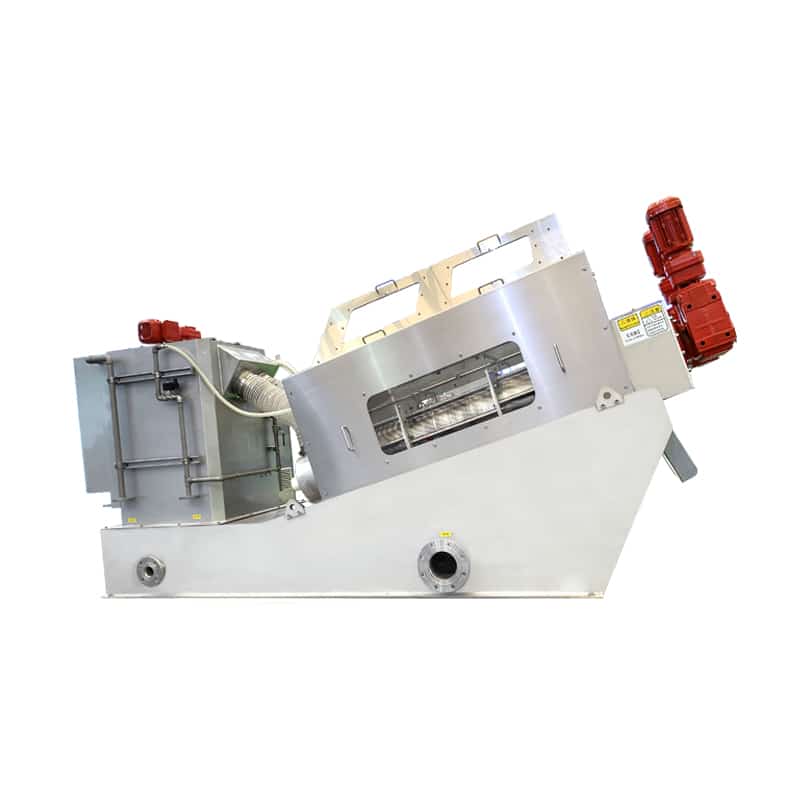

- Dewatering: The dewatering stage further reduces the water content in the sludge, bringing its form closer to a solid. Equipment typically used in this step include centrifuges, belt presses, plate and frame presses, screw presses, etc.

- Stabilisation/Digestion: The objective of this step is to reduce the organic content of the sludge, preventing the development of malodours during treatment and disposal, and also to kill pathogens. This stage is generally carried out using anaerobic or aerobic digestion, corresponding to the main equipment anaerobic digestion tank, aerobic digestion tank.

- Drying: Drying is the last step of sludge treatment, which is mainly to further reduce the water content of sludge, reduce the volume of sludge, and facilitate its transport and final disposal. In the drying process, commonly used equipment includes sludge dryers.

- Final Disposal: The treated mudcake can be disposed of in different ways such as landfill, incineration or soil improvement.

Sewage Sludge Water Quality Parameters

| Parameter | Description |

| PH | The pH of water, which generally ranges from 0 to 14 |

| BOD | An important indicator of the concentration of organic matter in wastewater |

| COD | Reflects the amount of organic matter and some inorganic matter in the effluent |

| SS(suspended solids) | Suspended matter in sewage, including organic and inorganic matter |

| NH3-N (ammonia nitrogen) | Concentration of ammonia nitrogen in sewage |

| TP (total phosphorus) | The total amount of phosphorus in wastewater |

| TN (total nitrogen) | The total amount of nitrogen in wastewater |

| TSS (total suspended Solids) | The total amount of all substances present in solid form in sewage |

| VSS (volatile suspended solids) | The total amount of suspended solids in sewage that can be volatilised, mainly organic matter |

Sewage Sludge Incineration

Why sludge incineration?

Incineration is a pyrolytic process that takes place at high temperatures and converts organic material into harmless gaseous and solid substances such as carbon dioxide, water and inorganic salts. The process usually takes place in an incinerator at temperatures typically as high as 800 to 1,200 degrees Celsius. Incineration reduces volume and destroys hazardous substances. For treating large quantities of sewage and sludge, incineration can be a fairly effective and reliable method.

Sludge Incineration Process

- Pre-treatment: Pre-treatment refers to the initial treatment of raw sludge to facilitate subsequent incineration. This includes operations such as dewatering, drying and shredding.

- Heat treatment: The pre-treated sludge is sent to an incinerator for heat treatment. Under high temperature conditions, the organic substances in the sludge are oxidised and decomposed into water vapour, carbon dioxide and other harmless or low toxicity gases.

- Exhaust gas treatment: Exhaust gases from heat treatment require strict treatment to prevent harmful substances from being released into the atmosphere. General treatment methods include electric dust removal, wet washing, activated carbon adsorption and denitrification.

- Waste residue treatment: Incineration produces a portion of solid residue, also known as incineration ash. Incineration ash may contain some heavy metals and other toxic and hazardous substances, which need to be stabilised before final disposal.

- Energy recovery: During the incineration process, thermal energy is released from the sludge. With appropriate devices, this energy can be recovered for power or heat generation.

This is the basic process of sludge incineration. The exact modus operandi and steps may vary according to the actual situation, but the overall objective is to minimise pollutant emissions while recovering and utilising as many resources as possible.

Advantages And Disadvantages of Sludge Incineration

Advantages

- Significant reduction in volume

- Elimination of pathogens

- Reduction of pollutants

- Resource recovery

Disadvantages

- High investment and operation cost

- Secondary pollution

- High energy consumption

- Low public acceptance

Summary

Sewage sludge incineration is a treatment method that burns sludge generated during sewage treatment at high temperatures to reduce its volume, eliminate harmful substances, and convert it into reusable energy and harmless ash. Its main advantages include significant volume reduction, complete destruction of hazardous substances, and the possibility of reusing resources.KUOSI provides wastewater treatment equipment such as filter presses, hydraulic filter press and automatic filter press. KUOSI also offers wastewater treatment equipment such as coarse screen and fine screens, roots blowers, dosing systems, grit classifier, ozone generators, sodium hypochlorite generators, and more. Contact KUOSI for a quote on equipment or to inquire about industry solutions.