Sludge is an unavoidable by-product of wastewater treatment – a semi-solid mixture rich in organic matter, microorganisms, heavy metals and nutrients. While the focus of wastewater treatment is on purifying the water, the proper disposal of sludge is equally critical – it’s a matter of environmental safety, regulatory compliance, and sustainable resource utilization.

In this article, we’ll take a closer look at a variety of sludge disposal methods, from traditional landfills to advanced energy recovery.

What is Sludge?

Sludge refers to a mixture of solids and pollutants separated from water during sewage or drinking water treatment, usually in a dark brown or grayish-black semi-solid or thick state.

| Source Process | Sludge Type | Characteristics |

| Primary Treatment of Municipal Wastewater | Primary Sludge | Contains large amounts of organic matter, impurities and particulate matter |

| Activated sludge system | Waste Activated Sludge | Bioflocs after microbial metabolism, with high water content |

| Drinking water plant sedimentation system | Water Treatment Sludge | Containing coagulant precipitation residue, fine particles, more difficult to dewatering |

| Industrial wastewater treatment systems | Industrial Sludge | Complex composition, may contain heavy metals, oil or toxic substances |

Table of sludge sources

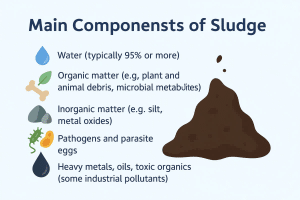

The Main Component of Sludge

- Moisture (often up to 95% or more)

- Organic matter (e.g. plant and animal debris, microbial metabolites)

- Inorganic matter (e.g. sediment, metal oxides)

- Pathogenic bacteria and parasite eggs

- Heavy metals, oils, toxic organics (some industrial pollutants)

Importance of Sludge Treatment

Sludge treatment plays a key role in the overall water treatment system, not only in terms of environmental protection and public health, but also in terms of operating costs, resource recovery efficiency and regulatory compliance.

Prevent Secondary Pollution

Untreated sludge contains a large number of harmful substances, such as pathogenic bacteria, heavy metals, organic pollutants and odorous substances. If it is directly discharged, it will cause serious pollution to water bodies, soil and air, and even jeopardize human health.

Reduce Volume and Transportation Costs

Sludge contains more than 95% water and is bulky and difficult to transport in its original state. Through thickening and dewatering, the volume and weight can be significantly reduced for subsequent disposal and transshipment.

Realize Resource Recovery And Recycling

- Agricultural fertilizer (stabilized as biosolids)

- Bioenergy (anaerobic digestion to produce biogas)

- Building material additives (ash slag after incineration for cement, bricks)

Reducing the Operational Burden of The Treatment System

If sludge is left untreated for a long period of time or improperly treated, it can cause sewage treatment systems:

- Repeated contamination

- Equipment fouling and clogging

- Unstable system operation

Meet Regulatory Requirements

Environmental regulations in various countries impose strict requirements on sludge discharge, disposal and resourcing. A standardized sludge treatment process helps companies avoid fines, lawsuits and policy risks.

Sludge Treatment Methods

Sludge treatment methods are usually divided into two stages: Pre-treatment (including reduction and stabilization) and final disposal (or resource utilization). Each method is selected according to the source, nature and treatment objectives of the sludge.

Pretreatment Stage

1️⃣ Thickening

Purpose: Reduce the volume of sludge for subsequent processing

Methods include:

- Gravity thickening (most commonly used)

- Air flotation thickening

- Centrifugal thickening

- Belt gravity thickening, etc.

2️⃣ Stabilization

Purpose: Reduces organic activity, inhibits spoilage and odors

Common methods:

| Methods | Principles | Characteristics |

|---|---|---|

| Anaerobic Digestion | Microorganisms break down organic matter in an anaerobic environment | Biogas production, energy recovery, significant reduction |

| Aerobic Digestion | decomposition of organic matter in an oxygenated environment | short time, suitable for small and medium-sized systems |

| Lime Stabilization | Lime is added to adjust pH to >11 to inhibit microorganisms | Simple and quick, but increased volume |

| Thermal treatment | kills pathogenic microorganisms by high temperature | high cost, high energy consumption |

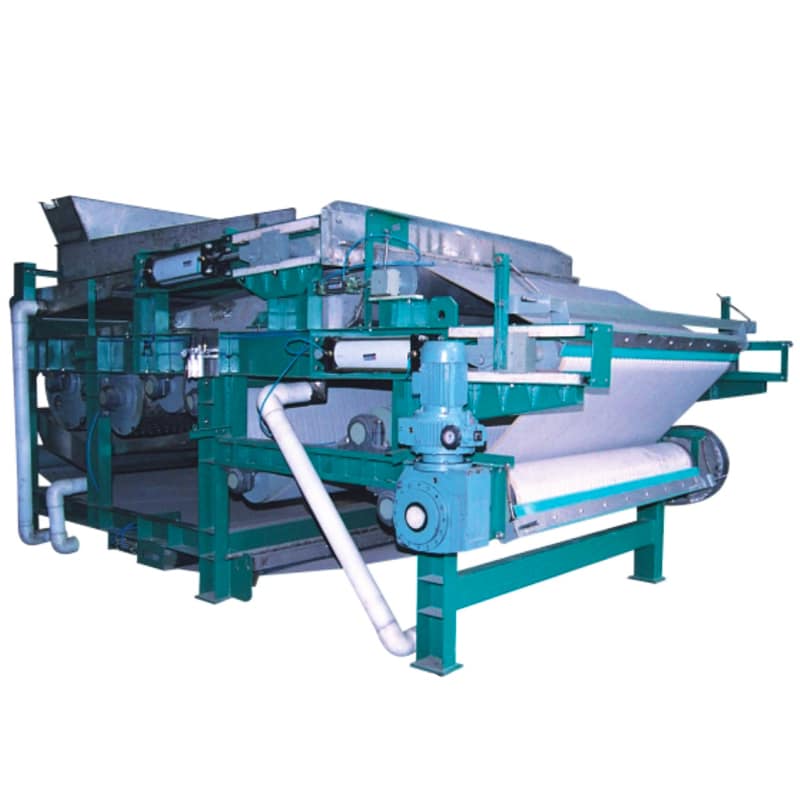

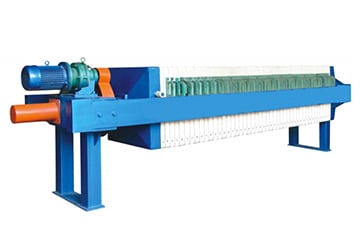

3️⃣Dewatering

Purpose: Further reduction of water to form a transportable sludge cake

Commonly used equipment:

- Plate and frame filter press

- Belt filter press

- Centrifugal dewatering machine

- Screw presses

The water content of sludge can generally be reduced to 60~80% after dewatering.

Final Disposal Phase

1️⃣ Sanitary Landfilling

Applicable to stabilized non-hazardous sludge that requires containment & leachate treatment, which has been gradually reduced in use.

2️⃣ Incineration

Incineration of sludge at temperatures above 850°C can substantially reduce capacity and realize partial energy recovery. However, the cost is high and emissions need to be strictly controlled.

3️⃣ Land Use (Land Application)

Such as biosolids fertilization, heavy metal and pathogen content needs to be controlled, applicable to agriculture, forestry or horticulture.

4️⃣ Composting (Composting)

Mix sludge with straw, sawdust, etc. for aerobic fermentation, and finally form organic fertilizer, suitable for municipal or gardening.

5️⃣ Advanced Resource Utilization

Such as:

- Anaerobic digestion to produce biogas

- Pyrolysis gasification: convert sludge into synthesis gas, carbon black

- Building materials utilization: e.g. sludge ash sludge to make bricks, mixed with cement, etc.

New Technology for Sludge Treatment

Thermal Hydrolysis Process

The sludge is pretreated at high temperature (160~180°C) and high pressure to destroy the cell structure and release the organic matter.

Advantage:

- Improve anaerobic digestion gas production efficiency (can be increased by 30~50%)

- Reduce the amount of residual sludge

- Improve dewatering performance (drier sludge cake)

Thermophilic Anaerobic Digestion

Increase the temperature of traditional anaerobic digestion to 50~60°C to increase the microbial reaction rate.

Advantage:

- Increased biogas production

- More complete pathogen inactivation

- Suitable for high load sludge treatment systems

Electro-dewatering / Electrolysis

Water is driven away from the sludge by a DC electric field or the sludge structure is destroyed in the electrolysis process.

Advantage:

- Highly efficient dewatering, water content can be as low as 40% or less

- No chemicals required

- Suitable for high end dryness requirements (e.g. pre-treatment before incineration)

Wet Air Oxidation

The organic matter in sludge is oxidized by air under high temperature and pressure to produce CO₂, water and harmless residue.

Advantage:

- No additional fuel required

- Suitable for difficult to degrade sludge (e.g. oily, chemical waste sludge)

- Effluent can be reused and residue can be landfilled or utilized

Intelligent Sludge Treatment System (AI+IoT)

Integrated sensors + automatic control + data modeling for intelligent regulation and remote management of sludge treatment processes.

Application:

- Real-time monitoring of key parameters such as dewatering rate, dosage, energy consumption, etc.

- Optimize equipment running time and load, energy saving and consumption reduction

- Realize early warning, anti-clogging, anti-corrosion and other automatic responses

Treatment of Sludge to Reduce Odor Emissions

The odor problem is one of the key challenges in O&M during sludge treatment, especially during sludge storage, conditioning, dewatering, drying or loading, which is prone to the generation of odorous substances such as volatile sulfides (e.g., H₂S), ammonia, and volatile fatty acids (VFA).

Chemical Deodorizer Pretreatment

Addition of iron salts (e.g. FeCl₃): they react with H₂S to form a precipitate and reduce the release of odors.

Add deodorant (zinc citrate, quaternary ammonium salt, etc.) to neutralize volatile gases.

| Control measures | Principle | Suggested implementation location |

| Enclosure equipment/structure | Avoiding the spread of odors | Sludge storage tank, dosing tank, dewatering machine room, etc. |

| Negative Pressure Extraction + Air Hood | Concentrate the odor into the treatment system | Closed dewatering room, composting workshop |

| Ventilation system | Dilute the gas concentration and reduce localized build-up | Operation workshop, sludge storage room |

Table Of Chemical Deodorizer Pretreatment

End deodorization System

1️⃣ Activated Carbon Adsorption Tower (suitable for low concentration)

- Adsorption of NH₃, H₂S, VOCs, etc.

- Compact structure, suitable for small and medium-sized items

2️⃣ Biofiltration tank/bio-drip Filter Tower (green)

- Decompose odor molecules through microbial metabolism

- Low running cost, suitable for municipal wastewater plants

3️⃣ Chemical Scrubber Tower (suitable for high concentration)

- Neutralization of odor components by acid/alkali/oxidant spraying

- Suitable for industrial sludge or high intensity odor scenarios

Summary

Sludge is not merely a by-product of wastewater treatment—it’s a critical element that reflects the efficiency, sustainability, and environmental responsibility of any water treatment system. From improving dewatering performance to reducing odor emissions, adopting advanced technologies, and exploring resource recovery pathways, modern sludge management is evolving into a more integrated, intelligent, and eco-conscious discipline.

Sludge treatment is not a simple mechanical dewatering, but a systematic management of the environment, resources and technology, Kuosi combines environmental protection concepts and engineering practices, and continues to export high-quality equipment and solutions to help our customers effectively deal with treatment problems, meet emission standards and realize resource recovery. If you are planning or upgrading your sludge treatment system, please contact us for customized advice and technical support.