Seawater is one of the world’s abundant natural resources, but before it can be utilized, it needs to be treated to ensure its safety and suitability. seawater Electrochlorination technology provides an efficient and environmentally friendly way to convert seawater into a tool for disinfecting water.

What is electrochlorination?

Electrochlorination is a chemical process that uses an electric current to produce chlorine gas or hypochlorite, either directly or indirectly. The process usually involves the electrolysis of a chloride solution or brine to produce chlorine gas (Cl2) or hypochlorite (e.g., sodium hypochlorite) through electrolysis. These resulting chemicals are commonly used as disinfectants and bleach, and are also used in a wide range of applications such as water treatment, wastewater treatment, disinfection, and industrial production.

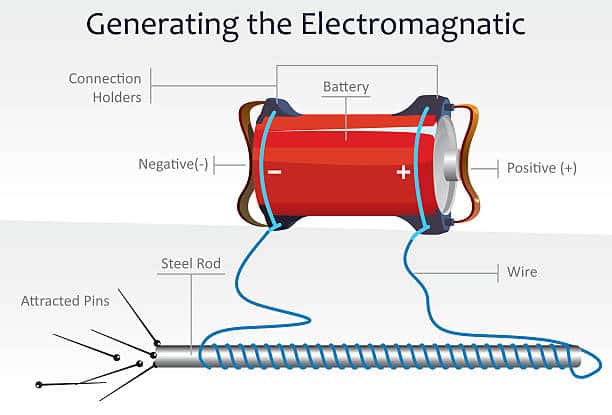

Electrochlorination usually occurs in an electrolyzer, which contains two electrodes (cathode and anode). When an electric current (usually direct current) is passed through the electrolyzer, salt compounds dissolved in water undergo electrolysis to produce chlorine gas or hypochlorite, depending on the electrolyte and current density.

Electrochlorination is a common disinfection method in water treatment, which can effectively kill microorganisms and harmful substances in water, and is widely used to disinfect drinking water, swimming pools, and industrial wastewater treatment.

Electrochlorination and aqueous chlorination

Electrochlorination is the process of generating sodium hypochlorite through the electrolysis of salt water, while aqueous chlorination is the method of disinfection in which chloride is added to water to generate hypochlorite. The former involves the electrochemical generation of a disinfectant, whereas the latter involves the direct addition of chloride to water to provide a disinfectant treatment. Both methods are designed to provide disinfection, but are achieved in slightly different ways and produce slightly different disinfectants.

Process of seawater electrochlorination

Seawater electrochlorination is a technology that uses electrochemical principles to generate sodium hypochlorite (a disinfectant) in seawater. This technology is commonly used in water treatment processes and the following is the basic process of seawater electrochlorination:

- Electrolysis cell setup: First, an electrolysis cell is set up, which usually consists of an anode and a cathode and is filled with seawater. The anode and cathode are usually made of stable materials so that they will not be corroded or damaged by seawater during the electrolysis process.

- Electrolysis of seawater: Direct current is passed through the anode and cathode so that they are immersed in seawater. This leads to an electrolytic reaction in which the salt in the water (sodium chloride) decomposes into sodium hypochlorite and hydrogen gas. This process can be represented by the following reaction equation:

- At the anode (oxidation): 2Cl- → Cl₂ + 2e-

- At the cathode (reduction): 2H₂O + 2e- → H₂ + 2OH-

- Combined reaction: 2NaCl + 2H₂O → Cl₂ + H₂ + 2Na⁺ + 2OH-

- Generation of sodium hypochlorite: Chlorine gas (Cl₂) produced during electrolysis reacts with water molecules (H₂O) and hydroxide ions (OH-) in seawater to generate sodium hypochlorite (NaClO) and hydrogen gas (H₂). Sodium hypochlorite is a common disinfectant used to disinfect and purify water.

- Disinfection process: The generated sodium hypochlorite can be used for water treatment, which will be used as a disinfectant to react with microorganisms and harmful substances in the water to achieve the purpose of disinfection and purification of water.

This is the basic principle of seawater electrochlorination, whereby sodium hypochlorite is produced through electrolysis of seawater to disinfect and purify water. This technology plays an important role in the desalination and water treatment process, ensuring water safety and suitability.

What is the relationship between desalination and seawater electrochlorination?

Desalination

- Purpose: The goal of desalination is to remove salts and impurities from seawater to produce fresh water that can be consumed and used for other purposes.

- Methods: Common desalination methods include reverse osmosis (RO) and distillation.RO uses a semi-permeable membrane to separate salt from water, while distillation achieves salt removal by heating seawater and collecting the resulting steam before condensing it into fresh water.

Seawater electrochlorination

- Purpose: The main objective of seawater electrochlorination is to convert salt in seawater into sodium hypochlorite (a disinfectant) using electrochemical principles.

- Method: Electrochlorination usually occurs in an electrolytic cell where a brine solution is electrolyzed by an electric current to produce sodium hypochlorite and chlorine gas. This method is not intended to produce drinking water, but rather to produce a disinfectant or for water treatment to kill microorganisms and harmful substances in the water.

In general, desalination, which aims to produce fresh water for drinking and other uses, and electrochlorination of seawater, which aims to produce chemicals such as sodium hypochlorite for water treatment and disinfection, have different purposes and methods of implementation.

What is an important component in a sodium hypochlorite generator in seawater electrochlorination?

- Electrodes: Electrodes are one of the key components in sodium hypochlorite generators. They are usually made of corrosion-resistant materials, such as titanium alloy or other corrosion-resistant materials, to ensure that they can withstand the chemical reaction and electric current in seawater during the electrolysis process, while maintaining stable performance.

- Electrolyzer: The electrolyzer is the device that holds the electrodes and seawater. It needs to be able to hold the electrodes safely and ensure that the current can pass through the seawater efficiently, leading to the generation of sodium hypochlorite.

- Power and control systems: These systems include power supply and control devices to provide the appropriate current, voltage and control parameters for a stable and efficient electrolysis process. The control system also monitors and regulates the electrolysis process to ensure that the sodium hypochlorite generated meets predetermined standards and requirements.

- Brine (seawater) supply system: This system provides seawater or brine for electrolysis and introduces it into the electrolyzer for the electrolysis process.

Application areas of seawater electrochlorination

- Desalination: Seawater electrochlorination is commonly used in desalination plants to convert seawater into fresh water that can be used for drinking and industrial purposes. Through electrochemical methods, the salt (sodium chloride) in seawater is converted into sodium hypochlorite to disinfect and purify the water source.

- Water supply systems: Some coastal cities or island areas use seawater electrochlorination to convert seawater into a source suitable for water supply systems. This helps to eliminate bacteria and harmful substances from the water and ensures that the water quality meets drinking water standards.

- Ships and marine platforms: Facilities such as ships and marine platforms located far away from land often use this technology to treat seawater and ensure that it is safe and suitable for specific uses, such as drinking water, supplying machinery and equipment.

- Industrial water: Seawater electrochlorination is also used in the industrial sector for specific production processes to treat water and disinfect it to meet the requirements of industrial production.

Advantages of seawater electrochlorination

- High efficiency: seawater electrochlorination technology can efficiently disinfect and purify water. Sodium hypochlorite (NaClO) is produced through electrolysis of seawater, which can quickly and effectively kill microorganisms and harmful substances in the water.

- Environmentally friendly: Compared to traditional chemical disinfection methods, the process of seawater electrochlorination does not require the introduction of external chemicals. This means that there is no additional chemical waste or negative impact on the environment.

- Controllability: The technology allows for more precise control of the disinfection process. By adjusting the electrolysis equipment, the amount and intensity of disinfection water can be adjusted as needed to meet the needs of different scenarios.

- No need to store or transport chlorine: Traditional disinfection methods usually require the storage and handling of chlorine gas, whereas seawater electrochlorination directly generates chlorine gas when needed, avoiding the risks associated with chlorine storage and transportation.

- Suitable for seawater resources: For areas with no other source of fresh water, especially coastal cities or island areas, seawater electrochlorination offers the possibility of converting seawater into a usable water source.

Summary

Seawater electrochlorination technology has revolutionized water treatment. It utilizes electrochemical principles to convert the salts in seawater into sodium hypochlorite, providing an efficient and environmentally friendly way to convert seawater into a usable water source. This technology plays an important role in water supply systems, industrial water use and marine applications, contributing significantly to ensuring a safe, suitable and sustainable water source.

KUOSI provides filter press, screw press, paddle dryer, dissolved air floatation system, bar screen, dosing system, ozone generator, sodium hypochlorite generator and other waste water treatment machines. If you have questions, please feel free to contact us.