Effluent Treatment Plants (ETP) are vital facilities in the industrial and manufacturing sectors that are tasked with treating wastewater generated from production processes to ensure its safe discharge or reuse. The importance of ETPs has increased as environmental regulations have become more stringent and the need for sustainable water utilization has become more urgent.

Understanding Effluent Treatment Plants

What is effluent?

It refers to untreated raw water from various sources, often containing a variety of pollutants, hazardous substances, and wastes. These effluent may contain a wide range of organic and inorganic pollutants.

What are effluent treatment plants?

Wastewater may contain various types of wastes and the type and amount of these wastes depend on the source and nature of the wastewater. Some of the common types of wastewater wastes are listed below, for example:

- Organic Compounds: Industrial wastewater usually contains a variety of organic substances such as petroleum products, chemical residues, solvents and pigments.

- Heavy Metals: Some industrial processes release wastewater containing heavy metals such as lead, cadmium, chromium and mercury. These heavy metals have harmful effects on the environment and living organisms.

- Chemicals: Chemicals and additives used in industrial production may enter wastewater, such as acids, bases, salts and additives.

- Suspended Solids: Wastewater may contain suspended particles, sediments and solid wastes that need to be removed to purify the water.

- Microorganisms and Bacteria: Certain industrial wastewater may contain microorganisms and bacteria that can be harmful to water quality and the environment.

- Nitrogen and Phosphorus: Nitrogen and phosphorus are nutrients in wastewater, usually from domestic and agricultural wastewater. Excess nitrogen and phosphorus can lead to eutrophication of water bodies, triggering algae outbreaks and increased oxygen consumption.

- Drugs and Chemicals: Some drugs and chemicals may be discharged from domestic wastewater, adversely affecting water bodies and living organisms.

- Oil Pollution: Industrial wastewater and motor vehicle discharges may contain oil pollution, such as petroleum and petroleum products. Oil pollution can form a film on the surface of water bodies, affecting water gas exchange and ecosystems.

What is the difference between STP and ETP?

The main difference between STP and ETP is the source and nature of the wastewater being treated. STP focuses on treating municipal wasterwater or urban domestic wastewater, whereas ETP specializes in treating industrial and manufacturing wastewater, which may contain more chemicals and organic matter. As a result, their treatment processes and requirements may differ, with ETPs typically requiring more complex treatment processes to meet the challenges of industrial wastewater.

Water composition of Effluent treatment plants

| Ingredient | Numerical Range |

| Total Solids in Water(TDS) | 100 – 10,000+ |

| Suspended Solids(TSS) | 10 – 1,000+ |

| Chemical Oxygen Demand(COD) | 50 – 5,000+ |

| Biochemical Oxygen Demand(BOD) | 10 – 1,000+ |

| Nitrogen(Ammonia, Nitrite, Nitrate) | 1 – 100+ |

| Phosphorus | 0.1 – 10+ |

| Oil and Fat | 1 – 100+ |

| Heavy Metals | 0.01 – 10+ |

| PH | 6.0 – 9.0 |

| Temperature | 15 – 35 |

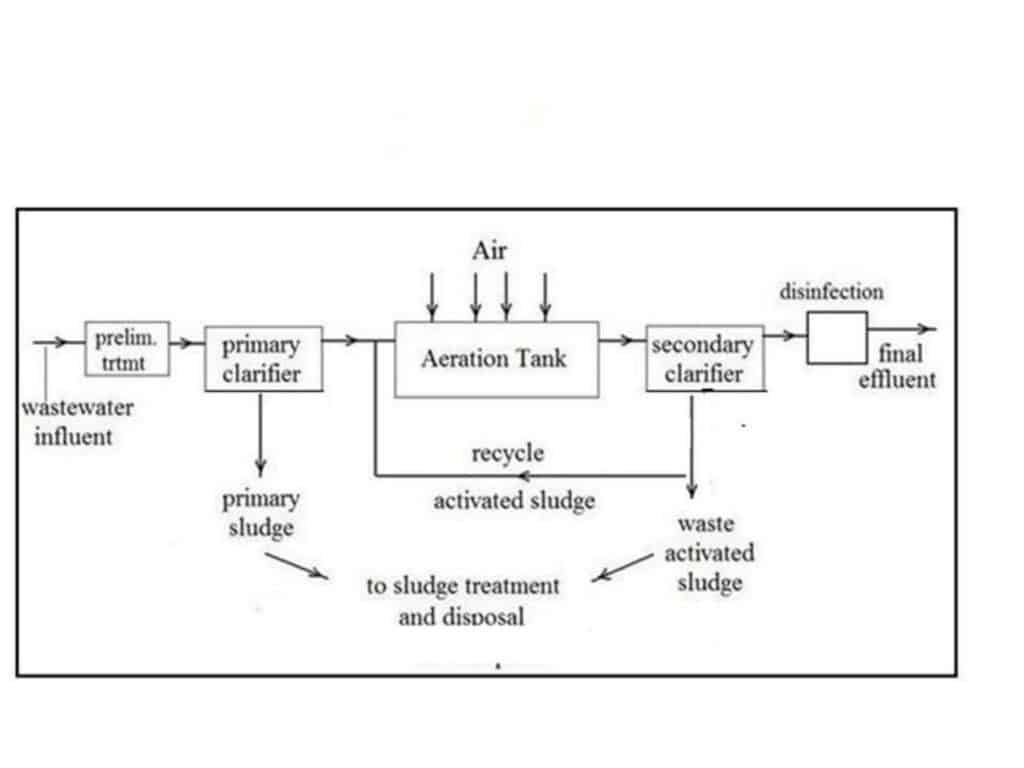

ETP Treatment Process

Pretreatment

Wastewater is conveyed from the source to the effluent treatment plants. before entering the ETP, it is initially screened through coarse screen or grizzly to remove large solids and suspended matter. Fine screens are then used to remove particles from the wastewater.

Primary Treatment

Wastewater enters a settling tank (clarified water treatment), usually a large storage area. Here, the wastewater sits, allowing heavy solid particles and sludge to settle to the bottom, formation of solid-liquid separation. Primary treatment helps to reduce wastewater solids s in the wastewater, thereby reducing turbidity.

Biological Treatment

For organic wastewater, the wastewater enters a bioreactor, which converts the organic matter in the wastewater to a stabilized form through biological activity that produces secondary sedimentation. Microorganisms degrade the organic matter into carbon dioxide and water.

- Bioreactors: Biological treatment is usually carried out in bioreactors. These reactors can be of different designs including activated sludge tanks, trickling filters, aeration tanks, aerobic digestion and anaerobic wastewater treatment. These reactors provide an environment conducive to microbial growth and activity.

- Microbial Attachment : A large number of microbial communities including bacteria, archaea, fungi and other microorganisms are introduced in the bioreactor. These microorganisms attach to fixed supports, packing or biofilter media and form biofilms to provide attachment surfaces to break down organic matter in the wastewater.

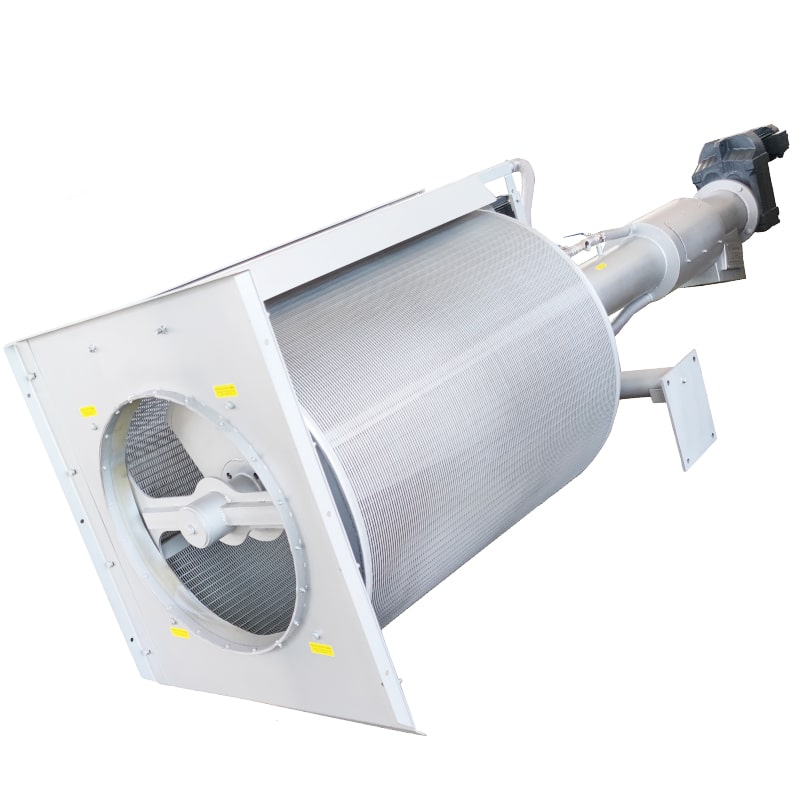

- Oxygen Supply: In the process of biological treatment, microorganisms need oxygen to break down organic matter. Consequently, an aeration system or oxygen supply equipment is typically used to inject oxygen into the reactor. Aeration, specifically roots blowers, plays a crucial role in the biological treatment process of wastewater treatment. The primary aim of aeration before deep treatment is to provide microorganisms in the effluent with oxygen, which helps promote biodegradation and the removal of organic matter. This is essential for maintaining a healthy biological community.

Secondary Treatment

The water from the bioreactor re-enters the settling tank to separate the residual sludge and microorganisms.

Deep Processing

After the treatment of wastewater, it may still contain harmful microorganisms that need to be eliminated. This is done through a process called disinfection. Chlorine or other chemicals are added to the wastewater to get rid of any remaining microorganisms before discharge into protected waters. To ensure all organics are removed from the wastewater, microfiltration, ion exchange, and activated carbon adsorption are used. Further removal of residual suspended solids and solid particles is also possible using a membrane filter press. For advanced treatment, additional disinfection steps like ultraviolet light disinfection or chlorine disinfection (sodium hypochlorite generators) are employed to kill any potential pathogens.

ETP Water Application Areas

Environmental Emissions

Agricultural Irrigation

Industrial Reuse

Groundwater Recharge

Water Supply

Summary

Effluent treatment plants plays a vital role in the treatment of industrial wastewater, helping to minimize adverse environmental impacts and ensuring the sustainable use of water resources.

KUOSI, as a leading water treatment manufacturer in China with more than 16 years of rich experience in the field of wastewater treatment, offers sludge dryers, dosing systems, disinfection systems and grit removal equipment. Please feel free to contact us.