Filtration principle of membrane filter press

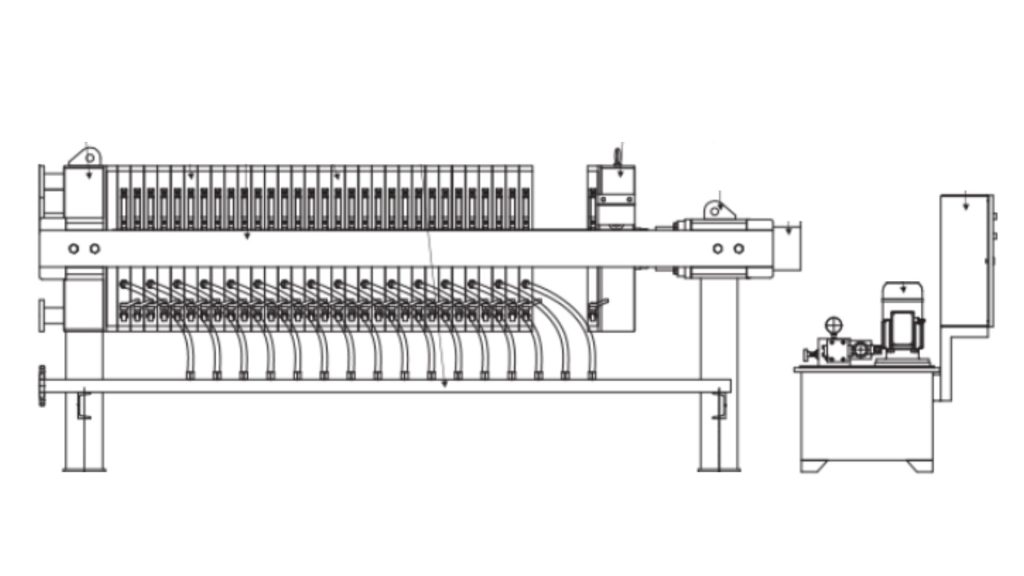

The basic components of a membrane filter press:

- Filter plates

- Membranes

- Filter cloths

- Hydraulic system

- Filter equipment frames

- Discharge system

- Control system

- Other ancillary components

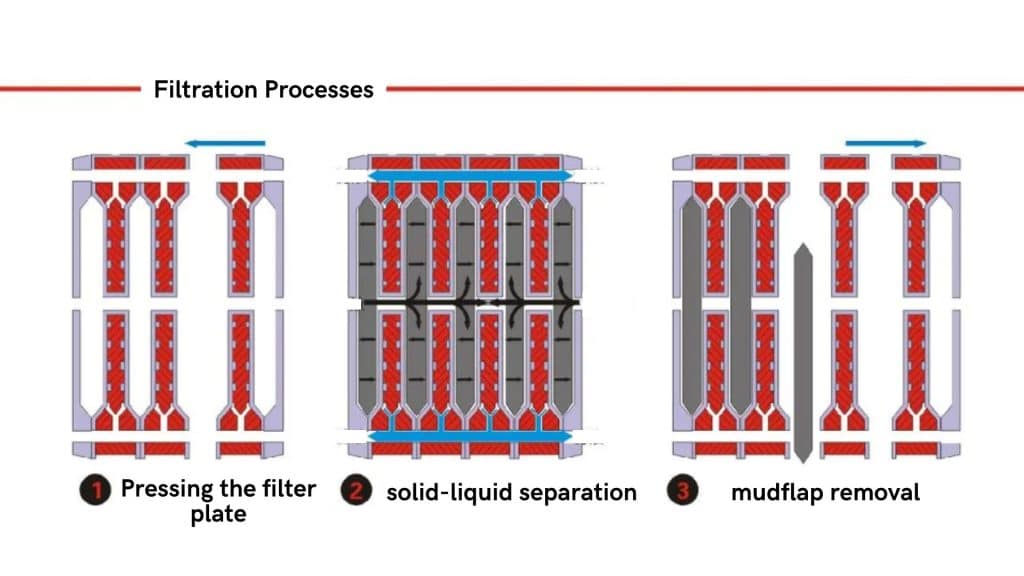

First, the filter plate is combined with the filter cloth to form a closed chamber. The suspension enters the chamber through a feed system and is forced through the filter cloth by pressure exerted by a hydraulic system or mechanical device. During the filtration process, the liquid portion (filtrate) passes through the filter cloth and out through the drainage system of the filter plate, while the solid particles are retained on the filter cloth and gradually form a solid cake.

In some cases, membrane filter presses can also perform a secondary squeezing operation to further increase the dryness of the solid cake and the yield of solids by increasing the pressure or changing the condition of the filter plate.

At the end of filtration, the filter plates are opened and the formed solid cake is removed from the filter cloth. Regular cleaning and maintenance of the filter cloth is necessary to ensure its filtration effect and life. Meanwhile, regular maintenance of the filter plate and other equipment components ensures stable operation and long-term reliability of the equipment.

Types of membrane plates for membrane filter presses

- Rubber membrane sheet

- Polypropylene (PP) membrane sheet

- Polyurethane (PU) membrane plate

- Cast iron membrane plate

- Stainless steel membrane plate

- Composite membrane plate

Membrane filter press feed method

Gravity feed

- Utilizing the gravity of the material, the slurry naturally flows into the filter chamber of the filter press through the pipeline.

- Simple equipment, low running cost.

- Suitable for materials with low viscosity and low solid content.

- The feeding speed is slow, not applicable to materials with high viscosity or high solid content.

- Suitable for small diaphragm filter presses or occasions with small processing capacity.

Pump feeding

- The slurry is transported to the filter chamber of the filter press using a feed pump, which can be centrifugal, screw or diaphragm pump.

- The feed speed is fast and can handle materials with high viscosity and high solid content.

- The feed pressure is controllable, which helps to improve the filtration efficiency.

- It needs to be equipped with corresponding pump and its control system, which increases the cost and complexity of the equipment.

- Widely used in various industrial processes, such as mining, chemical, food and pharmaceutical fields.

Pneumatic feeding

- Uses compressed air or inert gas to convey the slurry to the filter chamber of the filter press.

- Suitable for applications requiring explosion-proof and contamination-proof.

- Can handle volatile, flammable or toxic slurries.

- Higher equipment cost and higher gas source requirement.

- Mainly used in chemical, pharmaceutical and other industries with high environmental requirements.

Self-flow feeding

- Utilizing the high level difference of the material tank or storage tank, the slurry will be fed to the filter press by self-flow through the pipeline.

- The equipment is simple, easy to control and has low running cost.

- Suitable for continuous or semi-continuous production process.

- Require high fluidity of materials, not suitable for high viscosity or high solid content materials.

- Suitable for industrial processes with good material fluidity, such as sewage treatment, pulp and food processing.

Membrane filter press filtration cycle

The filtration cycle of a membrane filter press consists of four main stages: Feed, filtration, membrane press and discharge. The time and efficiency of each stage are affected by factors such as material characteristics, equipment parameters and operating conditions. By optimizing these parameters, the filtration cycle can be shortened and the processing efficiency and cake quality can be improved. Typically, the entire filtration cycle of a membrane filter press can range from 30 minutes to 2 hours, depending on the material being processed and the equipment configuration.

Feed stage:

Time: Usually takes 10-30 minutes.

Influencing factors: Slurry consistency, viscosity, feed pressure and speed.

Filtration stage:

Time: Overlaps with the feed stage, usually 10-20 minutes.

Influencing factors: Material and pore size of filter cloth, chamber design, uniformity of feed.

Membrane pressing stage:

Time: Usually between 10-30 minutes.

Influencing factors: Press pressure, material properties, membrane performance.

Unloading stage:

Time: Usually takes 5-15 minutes.

Influencing factors: Adhesion of the cake, design of the filter plate, efficiency of the unloading machinery.

Squeeze pressure in membrane filter presses

Low pressure membrane filter press

Pressure range: 0.8-1.0 MPa (about 8-10 bar)

Applications: Suitable for processing materials that are easier to filter, such as certain industrial wastewater or slurries with low solids content.

Medium pressure membrane filter press

Pressure range: 1.0-1.6 MPa (approx. 10-16 bar)

Application: For materials that require medium pressure for pressing, such as general municipal sludge, food processing waste, etc.

High pressure membrane filter press

Pressure range: 1.6-2.0 MPa (approx. 16-20 bar)

Application: For materials requiring high pressure for pressing, such as mine tailings, certain chemical wastes, high viscosity materials, etc.

Ultra high pressure membrane filter press

Pressure range: Above 2.0 MPa (over 20 bar)

Applications: For materials that are particularly difficult to dewater or for applications requiring extremely high dry solids content, such as special industrial wastes, high solids slurries, etc.

How are the membranes of a membrane filter press aerated?

Gas inflation: If compressed air is used, the compressed air enters the diaphragm chamber inside the filter plate through the inflation pipe. The compressed air gradually fills the diaphragm chamber, causing the diaphragm to expand from within.

Liquid inflation: If a liquid (e.g. water or oil) is used, the liquid is injected into the diaphragm chamber through the hydraulic system, similarly inflating the diaphragm.

Range of dry matter contents achievable with membrane filter presses

The range of dry matter content that can be achieved in a membrane filter press during solid-liquid separation depends on a number of factors, including the nature of the material, the choice of filter cloth, the pressure of the press and the operating conditions. Typically, the range of dry matter content that can be achieved in a membrane filter press is as follows:

General industrial sludge:

- Dry matter content: 30%-50%

- Industrial sludge usually contains high organic and inorganic substances, and the dry matter content can be increased to 30%-50% by high pressure pressing with membrane filter press.

Mine tailings:

- Dry matter content: 50%-70

- Mine tailings have coarse particles that are easy to dewater, and a higher dry matter content can be achieved using a membrane filter press, generally between 50%-70%.

Municipal sludge:

- Dry matter content: 20%-40%

- Municipal sludge contains a large amount of organic matter and water, through the treatment of membrane filter press, the dry matter content can reach 20%-40%.

Chemical waste:

- Dry matter content: 40%-60

- Chemical waste has a complex composition, and through the efficient pressing of the membrane filter press, a dry matter content of 40%-60% can be realized.

Food processing waste:

- Dry matter content: 30%-50

- Food processing waste contains high organic matter, through the membrane filter press, it can achieve 30%-50% dry matter content.

Summary

Membrane filter presses, as key equipment in the field of solid-liquid separation, enable efficient treatment of suspensions and drying of solid filter cakes through precise process control and efficient operating methods. By optimizing the filtration cycle and squeezing pressure, the membrane filter press ensures high efficiency and stable operation. Their flexible feed and diverse membrane plate types make them widely used in various industrial applications, providing reliable solid-liquid separation solutions for production processes.

KUOSI offers not only membrane filter presses but also other types of filter presses, screw presses, sludge dryers, dosing systems, disinfection systems, blowers, wastewater screens, DAf, sludge conveyors and screening washer screw compactors. Please contact us if you need more information.