Pre-Treatment

What is wastewater pretreatment?

Wastewater pre-treatment is the initial treatment of wastewater before it enters the subsequent treatment unit. Its main purpose is to remove larger suspended solids, grease, sand and other impurities from wastewater in order to protect subsequent treatment equipment, improve treatment efficiency and reduce the load on subsequent treatment.

Purpose of wastewater pre-treatment

- Protect subsequent equipment: Prevent clogging, remove larger solid particles, fibers, etc. from wastewater and prevent subsequent pumps, piping and other equipment from being clogged. Extend the service life of equipment: Reduce wear and tear, reduce maintenance costs.

- Improve treatment efficiency: Reduce the load of subsequent treatment, remove most suspended solids and oil and grease, reduce the load of subsequent biochemical treatment, and improve treatment efficiency. Improve sludge properties, reduce sludge volume, improve sludge settling performance, favor sludge subsequent treatment.

- Improvement of effluent water quality: Remove large particle pollutants, directly improve the appearance of effluent water quality. Create good conditions for subsequent treatment: Remove part of organic and inorganic substances, and create good conditions for subsequent biological and chemical treatment.

Wastewater pretreatment process

Initial screening and segregation

- Screen: Wastewater first enters the screen, which is able to intercept and remove larger suspended solids in the wastewater, such as wood blocks, plastic bags, etc., to prevent these substances from entering the subsequent treatment equipment causing blockage or damage. Coarse screen is used to remove large pieces of floating material. Smaller suspended solids are removed using fine screens.

- Grease trap: For wastewater containing oil and grease, such as food processing wastewater, it will first enter the grease trap. The grease trap separates the oil and grease in the wastewater from the water by physical means (e.g. gravity separation) to avoid the oil and grease from entering the subsequent treatment system.

Multi Rake Bar Screen

Rotating Drum Screen

Screw Screen

Internally Fed Rotary Drum Screen

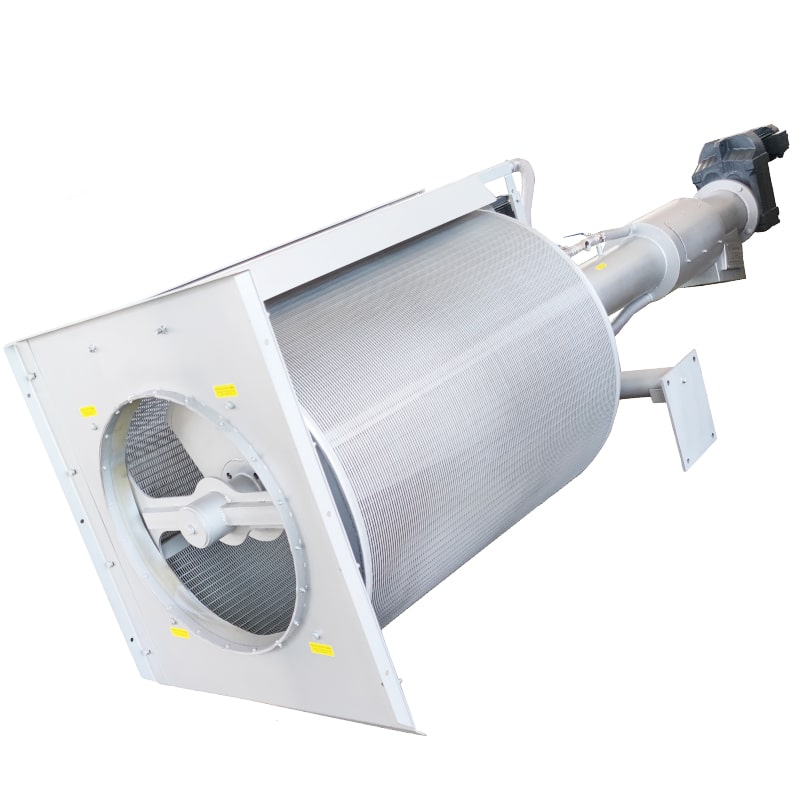

Externally Fed Rotary Drum Screen

Compact Pretreatment Plant

Physical treatment

- Sand Sedimentation Tank: After the wastewater enters the sand sedimentation tank, gravity is utilized to make the inorganic particles with larger specific gravity (e.g., sand particles, stone chips, etc.) settle to the bottom, thus separating them from the wastewater. This step helps to reduce wear and tear on the subsequent treatment equipment and reduces the suspended solids content.

- Conditioning Tank: Wastewater usually enters a conditioning tank before entering a subsequent treatment unit. The main purpose of the conditioning tank is to homogenize the water quality and quantity to ensure stable operation of the subsequent treatment unit. At the same time, the regulating tank can also carry out preliminary sedimentation and aeration and other treatments to further remove suspended solids and organic matter in the wastewater.

Grit Classifier

Screening Washer Screw Compactor

Combined chemical and physical treatment

- Coagulation and precipitation: For wastewater containing more suspended solids and colloidal substances, coagulation and precipitation can be used for treatment. By adding coagulants (such as polymerized aluminum chloride, polyacrylamide, etc.) to the wastewater, the suspended and colloidal substances coagulate into larger particles, and then settle to the bottom by gravity. Coagulation and precipitation method can effectively remove suspended solids and some organic matter in wastewater.

- Air flotation: Air flotation is through the generation of adsorption of tiny bubbles to be attached to carry suspended particles, so as to bring them out of the water. This method is suitable for the treatment of density close to water and difficult to settle the suspended matter, such as oil and grease, algae and so on.

Polymer Preparation System

Dissolved Air Flotation (DAF) System

Other pretreatment techniques

In addition to the above common pretreatment techniques, there are some other techniques that are also widely used in wastewater pretreatment, such as:

- Microelectrolysis: under specific conditions, some organic matter and heavy metal ions in wastewater can be removed by microelectrolysis.

- Fenton oxidation: Using the strong oxidizing property of Fenton reagents (i.e. ferrous ions and hydrogen peroxide), the organic matter in wastewater can be oxidized and decomposed into inorganic matter.

Factors affecting the effectiveness of wastewater pretreatment

- Wastewater quality: Wastewater composition, concentration, temperature, etc. will affect the effect of pretreatment.

- Treatment equipment: the type, quantity and specification of the equipment will affect the treatment effect.

- Process parameters: flow rate, retention time, chemical dosage and other process parameters will affect the treatment effect.

Precautions

Process optimization: Different wastewater requires different pretreatment processes, which need to be optimized according to the actual situation.

Equipment maintenance: Maintain the pretreatment equipment regularly to ensure its normal operation.

Process parameter control: Strictly control the process parameters, such as flow rate, residence time, etc., to ensure the treatment effect.