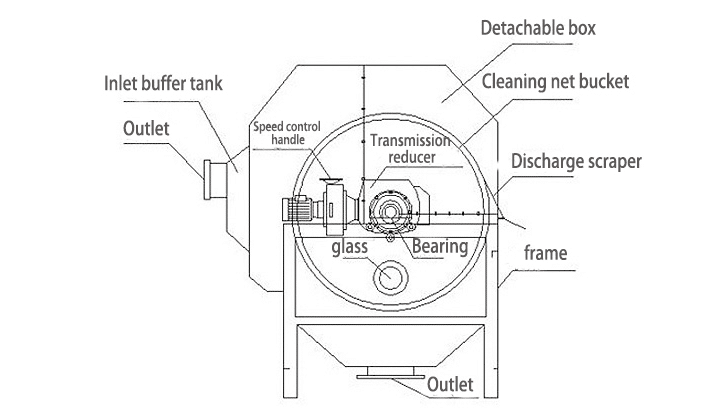

Externally Fed Rotary Drum Screen

The externally fed rotary drum screen is a reliable self-cleaning wedge wire screen that performs fine micro-screening for municipal wastewater treatment.

This screening technology performs particularly well in applications with wastewater containing high levels of oil or grease and in scum applications that may obscure other types of screens. It is used for fine screening of primary sewage influent at the head of the canal and for screening of clarifier flotsam.

The flow of suspended liquid for sieving is oriented with the surface of the rotating screen perpendicular to the holes between the rods. As the filtered liquid passes through the holes of the screen and discharges into the tank below the cylinder, the solids are trapped on the surface of the same screen and are attracted by rolling friction to the spillway vanes, which transfer them to a special container. The rods of the cylinder are wedge-shaped, allowing an uninterrupted flow of hydraulic pressure and minimizing the risk of solids sticking and causing blockages.

Working principle

The AC speed motor drives the grid cylinder through the reducer,and the sewage passes through the inlet valve to the water tank and rises to the filter water level through the uniformly distributed box plate.

The water enters the cylinder through the gap of the grid and is discharged from the bottom of the grid cylinder,and cleans the grid. The impurities and fibrous organic substances larger than the grid gap are blocked by the grid and carried to the other side of the cylinder by the rotating grid cylinder. After being discharged by the unloader to the slag hopper, the water content of the treated garbage is lower than 30%-50% than the original equipment. The filtered sewage flows into the outlet tank and is discharged through the drain.

Features

- It is made of high-strength and corrosion-resistant stainless steel, which has a small footprint and is convenient for construction. It can be directly fixed with expansion bolts. This device does not need to be grooved. Both inlet and outlet water can be connected by pipes.

- The screen has an inverted trapezoidal cross-section and the filter screen will not be blocked.

- It is controlled by a speed-regulating motor,which can keep it in good working condition according to the water flow.

- The special washing device can brush off a small amount of impurities stuck on the surface of the grid. After the barrel is internally washed twice, a good cleaning effect can be achieved.At the same time, a washing device is set to remove the dirt stuck on the mesh. Rinse.