The treatment and management of sludge and other wastes is becoming increasingly important in modern industrial and environmental fields. As an advanced solid-liquid separation equipment, the enclosed filter press is becoming the preferred choice for many industries due to its excellent performance and environmental friendliness. Compared with conventional filter presses, enclosed filter presses not only effectively reduce the leakage of contaminants and the spread of odors, but also greatly improve operational safety and filtration efficiency.

What is an enclosed filter press?

The enclosed filter press is an advanced solid-liquid separation equipment whose design is characterized by the fact that the entire filtration process takes place in a completely closed system. Enclosed filter presses offer higher efficiency, better environmental protection and greater operational safety than traditional open filter presses.

Specificities

- Closed system: All filtration processes take place in a closed environment, preventing contaminants from leaking into the external environment and ensuring the cleanliness and safety of the operating area.

- High-efficiency filtration: Capable of handling high concentration and high viscosity materials, providing efficient solid-liquid separation. Suitable for applications requiring high purity filtration.

- Automated control: Usually equipped with an automated control system to reduce manual intervention and improve operational efficiency. This makes the filtration process more stable and controllable.

- Environmentally friendly design: The closed system reduces pollutant emissions and odor diffusion, and is suitable for handling toxic, hazardous, or volatile materials, which is more friendly to the environment.

- Versatility: It can be equipped with a variety of filter cloths and filter media to meet different filtration needs and application scenarios.

Working principle of the enclosed filter press

- Feed stage

The pre-treated material is fed into the filter chamber of the filter press through the feed pump. The filter chamber consists of filter plates and filter cloths, which are arranged in a series of spaced chambers. The material is evenly distributed in these chambers. - Pressurized filtration

When the material enters the filter chamber, the filter press begins to apply pressure. Pressurization can be realized by hydraulic system or mechanical compression system. The purpose of pressurization is to push the liquid through the filter cloth so that the solid particles remain on the cloth and form a cake. The filtration medium is usually selected from suitable filter cloths, based on the characteristics of the material being processed. - Filtration process

In the process of applying pressure, the liquid (filtrate) is discharged through the small holes in the filter cloth and filter plate into the filtrate collection system. At this point, solid particles are trapped on the filter cloth and gradually form a filter cake. As filtration proceeds, the thickness of the cake increases and the flow rate of the filtrate slows down. - Filtrate discharge

The filtrate is discharged out of the equipment through the discharge channel on the filter plate and into the filtrate collection container. - Cake formation

As filtration proceeds, the solids in the filtration chamber continue to accumulate, forming a thick sludge cake. The thickness of the cake depends on the filtration time, applied pressure and feed concentration. - Cake removal

When the filtration process is complete, the filter press stops applying pressure. The filter plates of the filter press are loosened and the mud cake is stripped from the filter cloth and discharged by a mechanical or automatic discharge system. At this point, the cake is ready for subsequent processing, e.g., further drying of the cake using a paddle dryer and then sludge incineration. - Cleaning and preparation for the next cycle

After discharging the filter cake, the filter cloths and plates need to be cleaned to ensure the efficiency of the next filtration process. Automated enclosed filter presses are usually equipped with a self-cleaning system that effectively removes residues. Once cleaning is complete, the filter press re-compresses the filter plates in preparation for the next feed and filtration cycle.

Applications for Enclosed Filter Presses

- Wastewater treatment: In municipal and industrial wastewater treatment, the enclosed filter press effectively treats sludge, reduces volume and lowers subsequent treatment costs.

- Chemical industry: It is suitable for treating corrosive and toxic chemicals, ensuring the safety of operators and environmental protection.

- Pharmaceutical industry: Used in the production process of high-purity drugs to ensure the quality of the drugs and the cleanliness of the production environment.

- Food and beverage industry: Ensure hygiene and safety in the food production process and meet strict hygiene standards.

- Other industries: Such as mining, metallurgy and environmental protection, for solid-liquid separation and sludge treatment.

Comparison with conventional filter presses

| Comparison Dimension | Enclosed Filter Press | Traditional Filter Press |

| Design | Fully enclosed design, preventing pollutant leaks | Open design, potential risk of pollutant leakage |

| Environmental protection | Effectively reduces pollutant emissions and odor diffusion | Potential for pollutant emissions and odor |

| Operational safety | Suitable for handling hazardous materials | Higher risk when handling hazardous materials |

| Filtration efficiency | High filtration efficiency | Relatively lower filtration efficiency |

| Automation level | Equipped with automated control systems | Requires more manual operation |

| Maintenance | Easy to clean and maintain | Complex cleaning and maintenance process |

| Application scenarios | Suitable for various high-demand industries such as sewage treatment, chemical, pharmaceutical, and food | Mostly used in general industrial filtration processes, less common in high-demand scenarios |

Enclosed filter presses outperform conventional filter presses in a number of key aspects, particularly in terms of environmental protection, operational safety and filtration efficiency. Although enclosed filter presses have a higher initial investment, their high degree of automation and low maintenance costs make them more cost-effective in the long run.

Advantages of enclosed filter presses

- Preventing pollution spills

- Safe to operate

- Energy efficient

- Easy maintenance

- Automated system and advanced design

Common enclosed filter presses

Enclosed filter presses are compactly designed, safe to operate, environmentally friendly, and highly efficient filter presses that are commonly used in a variety of industrial and municipal wastewater treatment and solid-liquid separation processes. The following are some common types of enclosed filter presses:

Membrane filter press: Membrane filter press with closed chamber and membrane plate assembly, solid-liquid separation is realized by applying pressure, which is suitable for treating high-concentration sludge and solid-liquid separation process with special requirements.

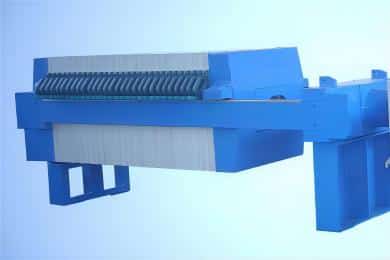

Plate and frame filter press: Plate and frame filter press adopts plate and frame structure, and puts the filter medium between the filter plates to form a filter chamber. The filter press applies pressure to squeeze out the liquid and form filter cake.

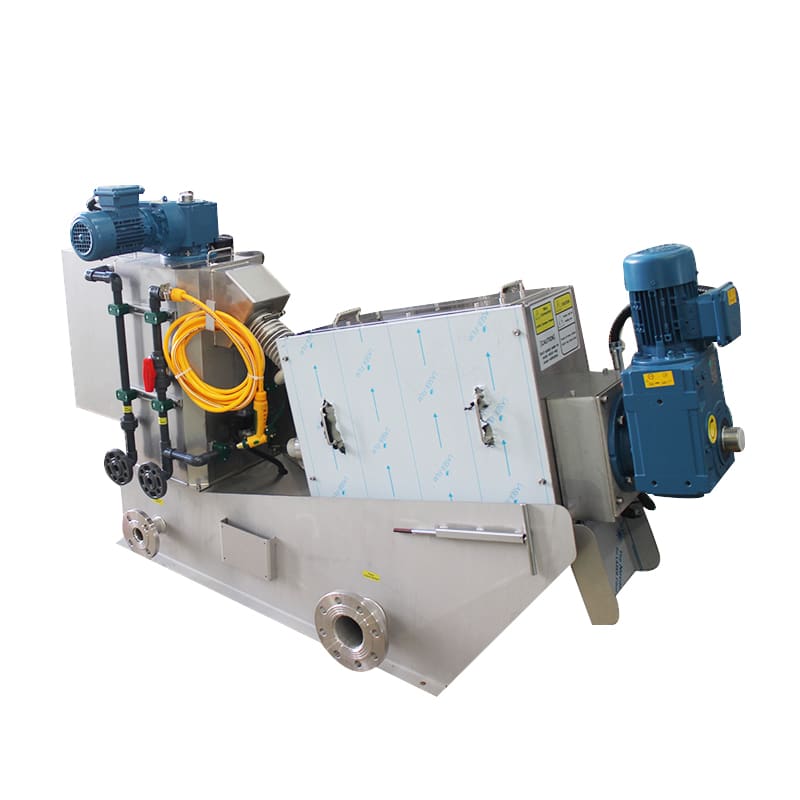

Screw press: Screw press by rotating the screw shaft, the liquid is squeezed out of solid particles to form filter cake. It is suitable for processing high viscosity and volatile substances.

Self-cleaning filter press: With an automatic cleaning system, the filter cloth and filter plate can be cleaned regularly to keep the equipment running efficiently. The enclosed design prevents operators from coming into contact with harmful substances.

Combination of DAF and closed filter presses

In conventional wastewater treatment plants, settlers separate sludge with a concentration between 0.5% and 2.0% dry matter (DM). This low-concentration sludge cannot be directly processed by filter-drying and therefore requires the use of a thickener. A thickener is a large and expensive piece of equipment that needs to be equipped with tanks, mechanical systems, and suitable transfer pumps. Sludge treated in a thickener can usually reach a dry matter content of 4 to 6% before it can be mechanically dried.

However, if a dissolved air flotation (DAF) system is installed instead of sedimentation and clarification equipment, an intermediate thickening process is not required. This is because the DAF system obtains a sludge with a dry matter content of between 3 and 10 percent, which effectively removes suspended solids and contaminants such as oil and grease. This provides a purer feed for subsequent treatment in a closed filter press, which improves the overall efficiency of the process.

Summary

Enclosed filter press is an efficient, environmentally friendly, and safe solid-liquid separation equipment for various industrial applications requiring strict filtration and pollution prevention. Its advanced design and versatility make it a widely used prospect in modern industrial production, making it an ideal choice for various industries to enhance filtration efficiency and safeguard environmental safety.

Kuosi manufacturers are not only concerned with the performance of their products, but they are also committed to environmental protection and sustainability. Our water treatment equipment helps companies reduce pollutant emissions, conserve water, and achieve environmental goals. Choose us to develop efficient water treatment solutions.