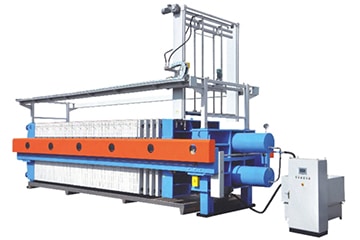

What’ s the oil filter press?

Oil filter press is a specialized filtration equipment for oil products. It filters out solid impurities, suspended matter, and particles from the oil by applying pressure to ensure the purity and quality of the oil. This equipment is widely used in the food processing, chemical, petroleum and pharmaceutical industries for the purification and clarification of various oil products such as edible oil, lubricating oil and fuel oil.

Oil Filtration Filter Press Features

- High efficiency filtration: It can effectively remove solid impurities, suspended matter and particles in oil, ensuring the purity of oil. During the filtration process, the solid impurities are retained on the filter cloth, forming filter cake, which further improves the filtration effect.

- Diversified design: Provide a variety of specifications and models, according to the need to increase or decrease the filtration unit, in order to meet different production requirements.

- Durable materials: Made of oil, high temperature and corrosion resistant materials, the key parts are often made of stainless steel to prevent rust and corrosion, which meets the sanitary standards of food and pharmaceutical industries.

- Automatic control: Equipped with PLC control system to realize automatic operation, reduce manual intervention and improve production efficiency.

- Easy to clean and maintain: Simple design, easy to disassemble and clean, reducing the time and cost of equipment cleaning and maintenance.

- Safe and reliable: Equipped with pressure protection device and temperature control system for oils that need to be heated to ensure that the filtration process is carried out at the right temperature.

Working Principle of Oil Filtration Filter Press

Preparation and Setup

- Filter plate and frame The filter press consists of a series of alternating filter plates and frames. The filter medium (filter cloth or paper) is placed between these plates.

- Feed pump: Used to supply the filter press with oil to be filtered.

Filling

- Oil inlet: The unfiltered oil is pumped into the filter press through an inlet port. The oil flows into the chambers formed by the filter plates and frames.

- Pressure application: The feed pump applies pressure to force the oil through the filter media. This pressure is essential to overcome the resistance of the filter media and any accumulated solids.

Filtration Process

- Solids retention: As the oil passes through the filter media, solid contaminants and impurities are trapped on the surface of the filter cloth, forming a layer of filter cake.

- Filtrate collection: The purified oil, now free of solid contaminants, passes through the filter media and is collected in the filtrate outlet channels.

Filter Cake Formation

- Gradual build up: Over time, the layer of solids builds up on the filter cloth. The thickness of this cake increases as more oil is filtered.

- Resistance increase: As the filter cake becomes thicker, it adds to the resistance against the flow of oil, requiring higher pressure to maintain the filtration rate.

Completion of Filtration

- Cycle end: The filtration process continues until the filter cake reaches a predetermined thickness or until the pressure required to continue filtration becomes too high.

- Discharge preparation: Once the filtration cycle is complete, the feed pump is stopped, and the pressure within the filter press is released.

Cake Discharge

- Plate separation: The filter plates are separated, usually by a hydraulic or mechanical system, to expose the filter cake.

- Cake removal: The filter cake is manually or automatically removed from the filter cloth. This step is crucial for preparing the filter press for the next filtration cycle.

Cleaning and maintenance

- Filter cloth cleaning: The filter cloth is cleaned to remove any residual solids that may affect the next filtration cycle. This can be done using water or a cleaning solution.

- Inspection and setup: The filter plates and cloth are inspected for wear and tear. Any damaged components are replaced, and the press is reassembled for the next cycle.

Advantages of Oil Filter Presses

- High efficiency filtration: effectively removes impurities and particles in the oil and improves the purity of the oil.

- Extend equipment life: Reduce contaminants in the oil, reduce equipment wear, and prolong service life.

- Cost Saving: Reduce the frequency of oil change and maintenance needs, and reduce long-term operating costs.

- Environmentally friendly: Reduce waste oil disposal and environmental pollution by cleaning and reusing oil.

- Widely applicable: Suitable for various oils, such as hydraulic oils, lubricants, and edible oils.

- Enhanced oil quality: Ensures that the oil meets high quality standards and is suitable for applications with high purity requirements.

- Automatic control: Modern equipment is equipped with an automated system for simple operation and reduced manual intervention.

Oil Filtration Filter Presses provide pure oil through efficient filtration and automated control, extending equipment life and reducing costs while being environmentally friendly and versatile.

Key Points for Selecting Oil Filter Presses

- Filtration capacity and efficiency: Choose a filter press that can handle the required oil volume and has the necessary filtration precision. Inadequate capacity can affect production efficiency.

- Type of oil: Different types of oil have varying viscosities. Select a filter press that can process the specific viscosity range. Consider the types and sizes of contaminants in the oil, and choose the appropriate filter cloth and filtration media.

- Operation and maintenance: Opt for a filter press with a high degree of automation. Designs that are easy to clean and maintain help ensure long-term efficient operation of the equipment.

- Material and corrosion resistance: The material of the filter press should withstand the chemical properties of the oil, especially when handling corrosive or high-temperature oil.

- Equipment size and space: Consider the dimensions and installation space of the filter press to ensure it can be installed in the designated location.

Filter Presses Suitable For Oil Filtration

Plate and Frame Filter Press

- Design: Plate and frame filter press consists of alternating plates and frames, similar to a sandwich structure.

- Efficiency: Provides high-efficiency filtration, capable of handling oils of different viscosities.

- Application: Suitable for filtration of lubricating oil, hydraulic oil and vegetable oil.

Membrane Filter Press

- Design: Membrane filter presses are equipped with flexible membranes that exert additional pressure on the filter cake.

- Efficiency: Increases dewatering efficiency and reduces the water content of the filter cake.

- Application: Ideal for oils with high solids content or requiring strict filtration standards.

Chamber Filter Press

- Design: Chamber filter presses have intaglio plates that form chambers to hold the filter cake.

- Efficiency: Provides excellent filtration for oils with medium to high solids content.

- Application: Commonly used in petrochemical industry and edible oil filtration.

Automatic Filter Presses

- Design: Automatic filter press Includes automated system for opening and closing plates and discharging filter cake.

- Efficiency: Reduces labor costs and improves filtration consistency.

- Application: For large oil filtration processes, emphasizing efficiency and automation.

Summary

Oil filter presses are specifically used to filter oil, by applying pressure to filter out impurities, suspended matter and particles in the oil to ensure the purity and quality of the oil, the filter cloth usually used should also be oil-resistant and high-temperature-resistant.

Kuosi manufactures water treatment equipment that is widely acclaimed for its durability and reliability. In addition to oil filter presses, there are also screw presses and paddle dryers that specialize in sewage sludge treatment, as well as wastewater screen in sewage pre-processing, air flotation, and ozone generator for further treatment of sewage, which, together with the dosing system, form a complete wastewater treatment system, so please feel free to contact us for further information on wastewater treatment solutions.