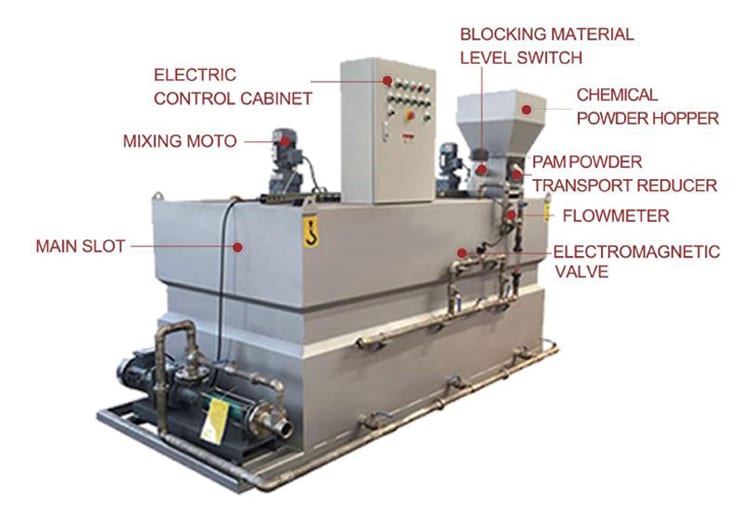

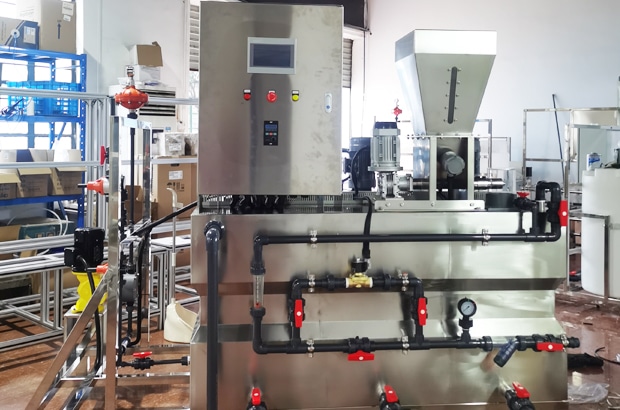

Polymer Preparation System

Polymer Preparation System is a compact automated metering unit for liquid or powder polymer preparation and dosing. Designed specifically for uniformity of flocculant concentration, the design is optimized to ensure that the polymer completes the maturation process with minimal footprint. Also often referred to as powder dosing systems, polymer dosing systems, PAM PAC dosing systems.

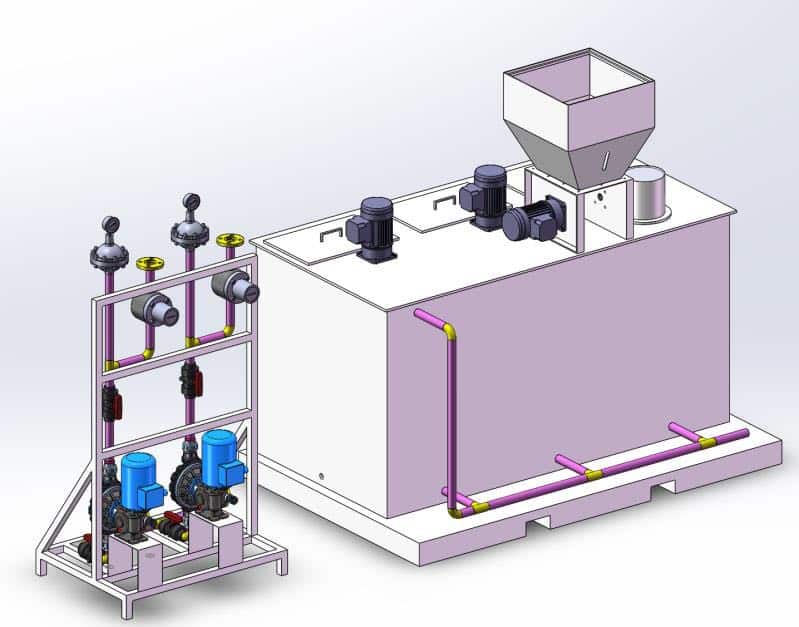

The pre-assembled polymer unit features two cylindrical chambers for dosing, maturation and storage of liquid or powdered polymer solutions, which are hydraulically coupled via overflow channels. In addition, two motorized stirrers provide agitation to ensure consistent performance.

KUOSI offers calibration of the powder dosing unit and concentrate pumps, and the system can be customized for HAOSH’s wide range of dosing pumps for market-leading flexibility.

How does polymer preparation system work?

For solids separation in water treatment applications where effective coalescence and flocculation are required prior to dosing, this dosing system can be used for batch flocculation aids to prepare ready-to-use polymer solutions and is designed for fully automated dosing of polymer solutions.

The baffles allow the polymer formulation to circulate through a series of compartments. This ensures optimal reaction times and continuous concentration levels in each compartment, thus avoiding any preferential routes between the preparation compartment and the final dosing solution compartment.

Automation is achieved by a control panel connected to an ultrasonic level detector located above the dosing solution compartment. Once the solution in the dosing chamber reaches “low level”, the detector activates the opening of the inlet motorized valve and the activation of the dry feeder. The water meter continuously controls the flow rate. Once a “high level” is reached, the process cycle stops.

Features

- Fully automated operation — saves labor costs and prevents dosing errors, operation stops

- Standardization of the resulting polymer — concentration, maturation time, homogeneity

- High efficiency mixer — Provides low flow mixing for homogeneous flocculant polymerization without mechanical degradation

- Optimized process — visual access to process and alarms, can feed the process when needed, regulated by ultrasonic level switches

- Compact design — easy to transport and relocate

- Safe and reliable — operation with airlift and overflow protection

Applications

- Water treatment: flocculation of industrial and drinking water

- Wastewater treatment: physicochemical treatment

- Sludge treatment: centrifuges, screw presses, filter presses to improve dewatering

- Mining: concentrate sludge will sink to the bottom faster Speeds up production

- Paper industry: retention aid

- Cooling water treatment: inhibitors and biocides