Effective implementation of the filtration process ensures the purity of the sugar solution, the stability of the sugar quality, and helps to improve production efficiency and product quality.

What is a sugar filter press?

Sugar filter press is a specially designed filter press equipment used to separate molasses or sugar residue from cane juice or bagasse. It plays a key role in sugar mills, helping sugar producers to separate sugar from cane juice for use in making various sugar products.

Importance of filtration in sugar production

Filtration is a vital aspect in the production of sugar which is used for solid-liquid separation, clarification and extraction of pure sugar solution or sugar residue. Following are the importance of filtration link in sugar production process:

- Solid-liquid separation

Sugar cane juice clarification: Sugar cane juice contains impurities and solid particles, the solid particles are separated out by filtration to obtain clear sugar cane juice.

Beet juice filtration: beet pulp is filtered to remove solid particles and impurities to extract pure beet syrup. - Clarification

Syrup clarification: The concentrated syrup is filtered and clarified to remove impurities and coloring to extract pure syrup.

Honey clarification: The collected honey is filtered and clarified to remove impurities and solid particles from the honey. - Extraction

Sugar residue dehydration: The sugar residue in the syrup is filtered and pressed to extract the sugar solution for further crystallization and drying.

Fructose Extraction: Fructose syrup is filtered and clarified to extract a pure fructose product. - Crystallization

Crystallization of sugar: Through the process of filtration and crystallization, the sugar in the syrup is separated to form sugar crystals, which are used to make crystal clear white granulated sugar. - Decolorization

Decolorization of sugar syrup: Filtering and decolorization of sugar syrup to remove pigment and impurities, so as to make the color of sugar products more pure. - Refining

Molasses refining: Through the steps of filtration and decolorization, high purity sugar solution is extracted and used in the manufacture of different types of sugar products. - Sugar dregs treatment

Sugar dregs filtration: Filtration and pressing of sugar dregs to extract the uncrystallized sugar solution or syrup and recover the unextracted sugar.

How to choose a filter press for a variety of different sugar mills?

For different types of sugar mills, choosing the right filter press needs to consider a number of factors, including production scale, raw material characteristics, process flow, product requirements and budget. The following are suggestions for choosing a filter press for different types of sugar mills:

- Large-scale industrial sugar mills

Production scale: Large-scale industrial sugar factories usually need to process a large number of raw materials and products, and are suitable for selecting filter presses with high capacity and high degree of automation.

Recommended filter presses: Multi-functional filter presses, membrane filter presses with a high degree of automation or belt filter presses.

Reason: These equipments can adapt to large-scale production, improve production efficiency and automation level.

- Small and medium-sized sugar mills

Production scale: Small and medium-sized sugar factories are relatively small in production scale, so they can choose filter presses suitable for small-scale production.

Recommended filter presses: Plate and frame filter press, disc filter press, frame filter press.

Reason: these devices are simple to operate, easy to maintain, and suitable for small and medium-sized sugar mills.

- Sugar cane factory

Characteristics of raw materials: Processing cane juice, need to effectively separate suspended solids and impurities.

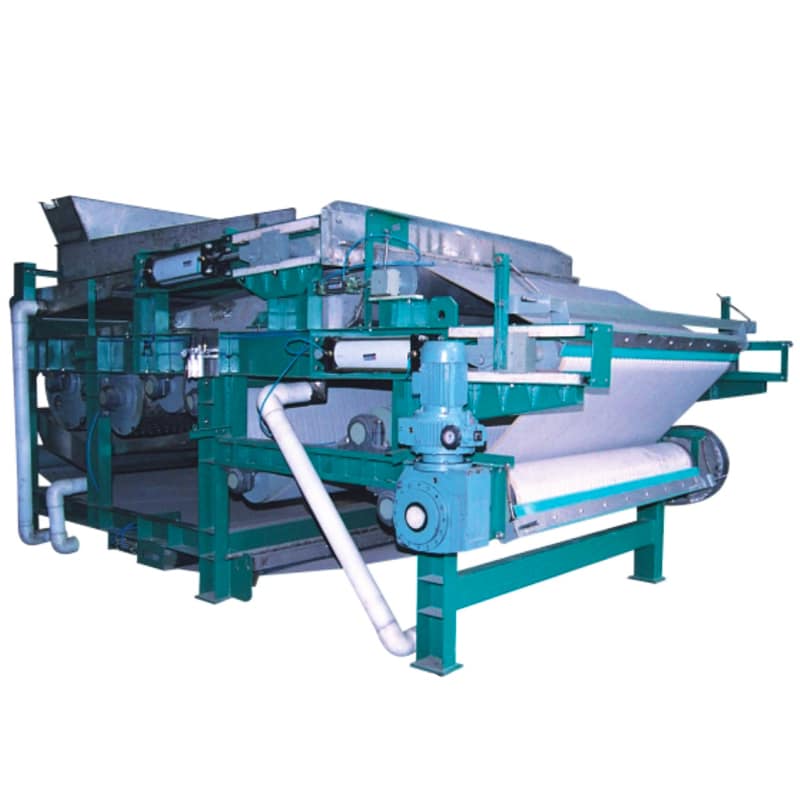

Recommended filter presses: Plate and frame filter press, membrane filter press, vacuum belt filter.

Reason: These machines are suitable for solid-liquid separation and clarification of cane juice to extract clear juice. - Sugar beet plant

Characteristics of raw materials: Processing sugar beet pulp requires efficient filtration and clarification equipment.

Recommended filter presses: Membrane filter press, plate and frame filter press.

Reason: These equipment can effectively separate and clarify the solid-liquid of beet pulp and extract pure beet syrup. - Multiple sugar manufacturers

Process: Need to adapt to a variety of sugar production processes, considering flexibility and versatility.

Recommended filter presses: Multi-function filter presses, and membrane filter presses with adjustable functions.

Reason: These machines can adapt to the needs of different process methods, improving flexibility and versatility in production. - Emerging sugar manufacturers

Budget: Limited budget, so cost-effective equipment needs to be considered.

Recommended filter presses: affordable plate and frame filter presses, disc filter presses.

Reason: These equipments are cost-effective and suitable for the budget and needs of emerging sugar producers.

Summary

Choosing the right filter press is crucial for improving the production efficiency and product quality of sugar mills. Different types of sugar mills should choose suitable filter presses according to their own production requirements, raw material characteristics and process flow to achieve the best production results and return on investment.

KUOSI offers not only sugar filter presses, but also screw presses, sludge dryers, dosing systems, disinfection systems, wastewater screens, blowers and DAFs. Please contact us if you need more information.