What is anaerobic wastewater treatment?

Anaerobic wastewater treatment is a biological process in which organic pollutants in wastewater are broken down with the help of microorganisms in the absence of oxygen. In anaerobic treatment, the wastewater enters the bioreactor vessel and contains a viscous semi-solid material called sludge, which consists of anaerobic bacteria and other microorganisms. These anaerobic microorganisms or “anaerobic bacteria” digest the biodegradable materials present in the wastewater, effectively removing the biological oxygen demand (BOD), chemical oxygen demand (COD) and total suspended solids (TSS) from the wastewater. Biogas is also produced, most of which contains methane and carbon dioxide. Biogas is treated and used as a fuel. Sludge is sometimes used as compost and fertilizer in agriculture. Often, aerobic and anaerobic treatment methods are used together to effectively remove pollutants.

Anaerobic wastewater treatment is used to treat wastewater from a variety of industries including agriculture, food and beverage, paper, textile, petrochemical and sewage containing high concentrations of organic matter, municipal sewage sludge and wastewater.

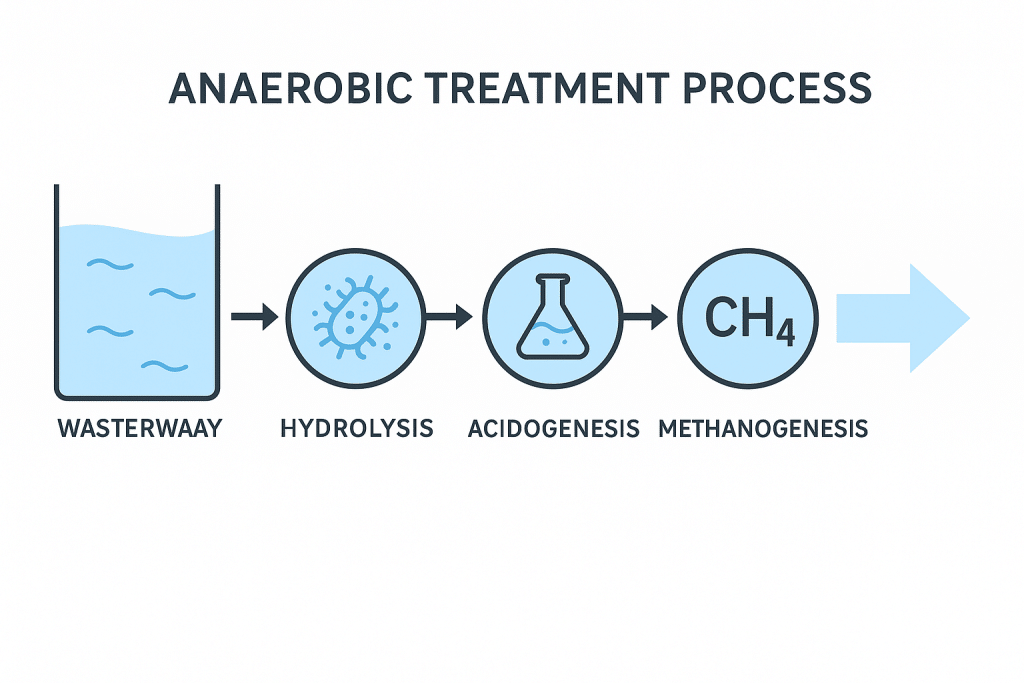

How does anaerobic wastewater treatment work?

Hydrolysis stage

- Hydrolysis stage (Hydrolysis)

Objective: to “cut” large organic molecules into small molecules, hydrolysis bacteria, hydrolysis enzymes (such as protease, lipase, amylase), hydrolysis is the anaerobic reaction of the “starting point”, if the hydrolysis is limited, the efficiency of the entire system will be reduced. - Acid production stage

Objective: fermentation of small molecules into volatile organic acids (VFA). Acid-producing and fermenting bacteria (parthenogenetic or specialized anaerobic), affect the pH and equilibrium of the system; control of this step prevents “acidification collapse”. - Acetogenesis

Goal: Convert the “complex intermediates” of the acidogenesis phase into acetic acid, H₂ and CO₂. High partial pressure of hydrogen can inhibit this process, so it is critical to maintain micro-ecological balance. - Methanogenesis phase

Goal: The final output of methane and carbon dioxide, is the core of energy recovery of the whole anaerobic system, methanogenic bacteria are extremely sensitive to the environment (pH, temperature, toxicity), is the key control point for the stable operation of the system.

Advantages of anaerobic systems

The advantages of anaerobic wastewater treatment systems compared to aerobic systems are.

- Wide range of application. Aerobic treatment can only treat organic wastewater with low and medium concentrations, while anaerobic treatment can treat all kinds of wastewater with high, medium and low concentrations.

- Less energy demand and can generate a lot of energy. Anaerobic treatment does not require oxygenation and produces huge amount of biogas, which can be used as energy.

- High organic load. The organic load of anaerobic treatment is generally 3.2~32 kgCOD/m3-d), and even up to 50 kgCOD/(m3-d).

- The amount of residual sludge is small and easy to handle, which effectively reduces the project cost. Due to the slow proliferation of anaerobic microorganisms, the amount of residual sludge generated is much less than aerobic treatment, and the sludge dewatering performance is good, so it is easier to treat.

- The demand for nutrients is small. Organic wastewater generally already contains a certain amount of nitrogen and phosphorus and a variety of trace elements, and anaerobic treatment can be done without adding or with less nutrient salts.

- Anaerobic strain is convenient for secondary start. Anaerobic treatment strains, such as anaerobic granular sludge, can retain their biological activity and good sedimentation performance for at least one year after termination of wastewater and nutrient supply, and this characteristic of it provides favorable conditions for intermittent or seasonal operation.

- High shock load resistance. The anaerobic treatment sludge is highly concentrated and can withstand large concentration changes and water quality changes.

- Flexible scale. The scale of anaerobic treatment system is flexible and can be large or small, and the equipment is simple and easy to make.

Types of anaerobic wastewater treatment systems

Anaerobic lagoons

This is a large man-made pond nearly 20 feet deep. Wastewater is introduced to the bottom of the lagoon, where it settles and forms a semi-solid sludge layer and an upper liquid layer.

The liquid layer prevents oxygen from reaching the sludge below, allowing anaerobic digestion to break down the organic pollutants in the wastewater. Optimal conditions are maintained. “warm water temperature” and “neutral pH” allow the anaerobic bacteria to effectively treat the pollutants, thus reducing the retention time of the wastewater.

Anaerobic lagoons are widely used for the treatment of agricultural wastewater due to meat reduction, the treatment of industrial wastewater, and the primary treatment of municipal wastewater.

Anaerobic sludge bed reactors

The wastewater passes through suspended sludge particles where anaerobic bacteria digest the organic pollutants in the wastewater, multiply and collect into larger particles, which then settle to the bottom of the reactor tank. At the same time, the treated effluent flows upwards out of the unit and the biogas produced is collected by a collection hood throughout the process.

Anaerobic sludge bed reactors are available in several different forms.

| Type | Features |

|---|---|

| UASB | Classic structure, moderate footprint, suitable for medium to high-strength organic wastewater |

| EGSB | Higher upflow velocity, more active granular sludge, high efficiency but requires precise operation |

| ABR | Multi-chamber baffled design, ideal for wastewater with fluctuating load |

Anaerobic filtration reactor

Anaerobic filtration reactors consist of a reactor tank equipped with some type of fixed filtration media. The anaerobic microorganisms will establish themselves in it to form a biofilm. The filter media varies from system to system and common materials include plastic films and granules, as well as gravel, pumice, bricks and other materials.

During the treatment cycle, the wastewater stream passes through the filter media, which is used to capture particles in the stream, while also providing sufficient surface area to expose the anaerobic bacteria in the biofilm to the organic material present in the stream.

Over time, the performance of the filter reactor must be carefully monitored as the filter media eventually becomes clogged with excessive biofilm and particulate buildup, requiring maintenance steps such as backwashing and cleaning to maintain optimal performance.

Summer

KUOSI has nearly 20 years of experience in the custom design and manufacture of water and wastewater treatment systems for a range of industries and applications, so please feel free to contact us with your questions. Contact us to schedule a project consultation with an engineer or to request an equipment quote. We can guide you through the steps of developing the right solution and realistic costs for your specific water treatment system needs.

We provide wastewater screens, dissolved air flotation systems, dosing systems, sludge dewatering equipment, sludge drying equipment, aeration blowers, disinfection systems and other types of wastewater treatment equipment, and are an integrated supplier of water treatment equipment and industry solutions.