Filter Presses in ETP

What is ETP?

ETP is a common term for wastewater treatment plant, standing for “Effluent Treatment Plant” which is used primarily to treat industrial wastewater or sewage to meet environmental discharge standards.

Meaning of Filter Press in ETP

In ETP, a filter press is typically a piece of equipment used for solid-liquid separation to separate solid particles from water in sludge, thereby reducing the solids content of wastewater and making it easier to treat or discharge. A filter press achieves solid-liquid separation by applying pressure to the sludge, pushing water out of the solids, and leaving solid particles in the filter media.

Role of Filter Presses in ETP

- Reduced solids content in wastewater: Separating solid particles from sludge reduces the concentration of suspended solids in wastewater, resulting in cleaner wastewater.

- Reduce wastewater treatment costs: Reducing the solids content of wastewater reduces the amount of chemicals used in subsequent treatment, energy consumption, and wear and tear on treatment equipment, thus reducing the cost of wastewater treatment.

- Improve wastewater treatment efficiency: Filter presses can treat large quantities of sludge quickly and efficiently, improving wastewater treatment efficiency and capacity.

- Conform to environmental discharge standards: The solid content of wastewater treated by the filter press is reduced, which makes it easier to meet the environmental discharge standards and protect the environment.

Working principle of ETP filter press

Sludge Feed: Sludge containing solid particles is piped to the inlet of the filter press.

Filter Pressing Process

- When the sludge enters the filter press, the filter inside the filter press is covered with filter cloth fixed to the filter plates.

- The hydraulic system of the filter press applies pressure to tightly press the filter plates together to form a sealed chamber.

- Due to the pressure difference, the water is forced out through the filter cloths, while the solid particles remain on the filter cloths to form a sludge cake.

Discharge of filtrate and sludge cake

- The filtrate is discharged through the filter cloth and out of the system through the discharge port.

- The sludge cake gradually accumulates on the filter cloth until the filter press reaches the set level of solid-liquid separation.

Cleaning the filter cloth:

- After a certain number of cycles, the filter press is stopped and the filter cloths are cleaned to remove residual solid particles and dirt.

- Usually high pressure water or other cleaning solution is used to rinse the filter cloth.

Recycling: The filter press continues to cycle through the process until all of the sludge has been processed.

This type of equipment is usually characterized by high efficiency and energy saving, and has a wide range of applications in industrial wastewater treatment.

Types Of Filter Presses At ETP

Plate and Frame Filter Press

Characteristics: Plate and frame filter press consist of plate and frame, the liquid enters into the plate and frame through the filter cloth, the solid particles are retained on the filter cloth and form the filter cake, then the solid-liquid separation is realized by applying pressure.

Applicable Scenario: It is suitable for treating sludge containing more solid particles, and can carry out solid-liquid separation quickly and efficiently.

Membrane Filter Press

Characteristics: Membrane is added on the basis of plate and frame filter press, and the pressure can be increased by the action of membrane to speed up the solid-liquid separation.

Applicable Scenario: Membrane filter press is suitable for processing sludge with high concentration and high viscosity, with higher processing efficiency and cleaner filter cake.

Screw type press

Characteristics: Squeeze the sludge from the inlet to the outlet through the spiral structure to realize solid-liquid separation.

Applicable Scenario: It is suitable for treating sludge containing fibers and large particles, and is suitable for continuous operation scenario.

Drum type filter press

Characteristics: Utilizes rotating drum and filter cloth to achieve solid-liquid separation, and squeezes water out of the filter cake through pressure.

Applicable scenarios: Suitable for treating sludge with high viscosity, continuous operation and automatic control can be realized.

Advantages of Filter Presses in ETP

- Efficient treatment: The filter press can quickly and efficiently separate the water from the sludge and improve the treatment efficiency.

- Reduced volume of wastewater: Reduces the volume of wastewater, saving the cost of subsequent treatment and discharge.

- Wide applicability: Suitable for treating various types of sludge, including organic sludge, inorganic sludge, mixed sludge, etc.

- Energy saving: Filter presses usually use hydraulic or mechanical pressure for solid-liquid separation, saving energy and power consumption.

- Automatic control: Modern filter presses are equipped with advanced automatic control systems, which can realize automatic operation, real-time monitoring and remote operation, reducing labor costs and operating difficulties.

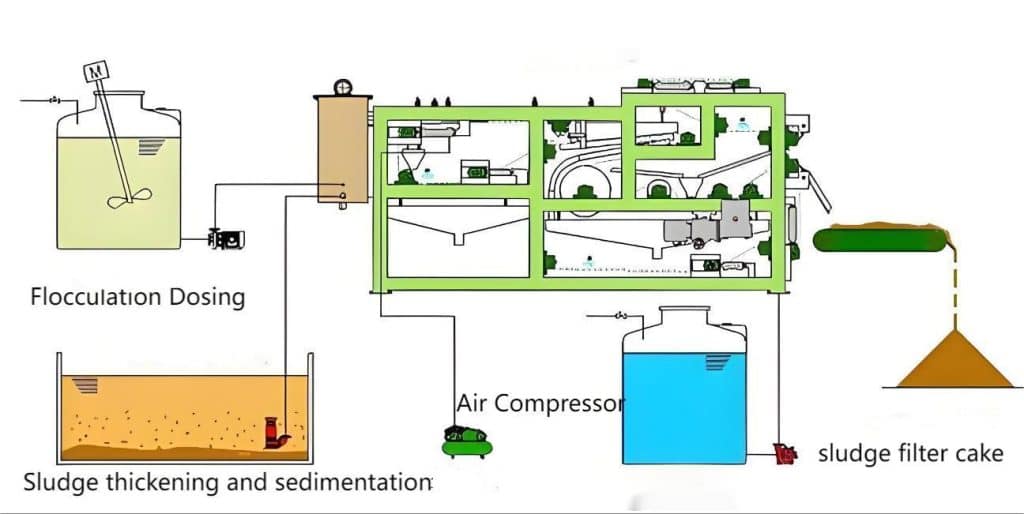

ETP Filter Presses With Other Equipment

- Coagulant dosing system: A coagulant dosing system is usually used to add chemical coagulants to wastewater to help aggregate suspended and colloidal particles into larger precipitates for subsequent treatment.

- Chemical Dosing Systems: Chemical dosing systems are used to add chemicals, such as oxidizing agents, reducing agents, neutralizing agents, etc., to wastewater to adjust the pH, oxidizing or reducing properties of the wastewater and to facilitate the removal or transformation of pollutants.

- Sludge thickening equipment: Sometimes the ETP filter press may not be able to meet the demand for handling large quantities of sludge, at which time it can be coupled with sludge thickening equipment, such as centrifugal dewatering machines or screw thickeners, to further thicken the sludge, reduce the treatment volume and improve the treatment efficiency.

- Wastewater pre treatment equipment: Usually there are also some wastewater pre-treatment equipment, such as grating, sand sink or air flotation machine, used to remove large particles of impurities, heavy metals, suspended solids, etc., in order to reduce the load on the filter press and improve the treatment efficiency.

- Wastewater post-treatment equipment: ETP filter press treated wastewater may still contain small amounts of suspended solids and pollutants that require further treatment to meet discharge standards.

Filter Press Maintenance

- Clean the filter cloth and filter plate regularly

- Check seals

- Lubricate parts

- Clean filter residue and sludge

- Check the control system

Summary

By understanding the maintenance and operation steps of ETP filter press, we can ensure the long-term stable operation of the equipment and improve the efficiency and quality of wastewater treatment.

KUOSI is a leading company specializing in the manufacturing of environmental equipment, dedicated to providing customers with high-quality and efficient solutions. We offer a range of products and equipment, low temperature sludge dryer, sodium hypochlorite generator, ozone generator, wastewater screen, etc. Contact us if you are interested in developing a program for you!