When treating wastewater and sludge, an effective dewatering process is crucial. Sludge dewatering polymers play a vital role in the dewatering process. These special polymers can help minimize the water content in sludge, thereby reducing the operating costs of wastewater treatment plants and increasing treatment efficiency.

What are sludge dewatering polymers?

Sludge dewatering polymers, also known as flocculants or coagulants, are chemicals used to treat sludge to improve dewatering efficiency. These polymers accelerate the settling and dewatering by aggregating suspended solid particles in the sludge and encouraging them to form larger clumps. Using sludge dewatering polymers can make the wastewater treatment process more efficient and produce a drier sludge cake and cleaner wastewater discharge. They are widely used and play a vital role in sludge treatment and wastewater treatment.

Types of polymers

There are various types of polymers in sludge dewatering, which commonly include:

- Cationic polymers: This type of polymer is positively charged and interacts with negatively charged particles in the sludge to form flocs during treatment. Cationic polymers are commonly used in the treatment of sludge containing organic matter, such as in sludge sewage treatment plants.

- Anionic polymers: In contrast to cationic polymers, anionic polymers are negatively charged. They can be used in conjunction with cationic polymers to balance the charge and enhance flocculation.

- Neutral polymers: These types of polymers are uncharged and are often used in specific sludge treatment situations, such as treating sludge containing high concentrations of inorganic salts.

- Blended polymers: Sometimes a blend of different types of polymers is used to achieve better flocculation and higher dewatering efficiency. Mixed polymers can be adapted to the type of sludge being treated and the water quality to meet specific treatment needs.

Selection of polymers for sludge dewatering

- Sludge nature: Different types of sludge (e.g. activated sludge, mixed sludge, sludge thickening, etc.) have different chemical compositions and properties, and therefore polymers need to be selected to suit the particular sludge type.

- Treatment objective: According to the treatment objective (e.g. degree of dewatering, sludge drying rate, etc.), polymers with suitable properties are selected to achieve the desired treatment effect.

- Polymer type: Select the appropriate type of polymer, such as cationic, anionic, or neutral polymer, based on the chemical properties of the sludge and the desired flocculation effect during the treatment process.

- Environmental impact: Consider the environmental friendliness of the polymer and its impact on other parameters of the treatment process, and select a polymer with a low environmental impact.

Sludge Dewatering Polymer Applications

Sludge dewatering polymers are mainly used in the purification of drinking water and industrial wastewater, the treatment of special water quality (such as oil-containing sewage, printing, dyeing and papermaking sewage, smelting sewage, radioactive substances, Pb, Cr, and other toxic heavy metals and fluorine-containing sewage, etc.). In addition, it is also widely used in precision casting, oil drilling, tanning, metallurgy, paper making, and so on.

Water Supply Treatment

Removal of turbidity and bacteria when using surface water as a source. Turbidity is generally less than 10 degrees after coagulation and sedimentation.

Wastewater Treatment

Industrial wastewater: For treatment of some special wastewater, decolorization, removal of suspended matter, etc.

Printing and dyeing wastewater treatment: It is suitable for the treatment of dye wastewater containing pigments, disperse dyes, water-soluble molecular weights and so on. The choice of coagulant is related to the type of dye and coagulation test is needed. Inorganic coagulants can be used alone or mixed with organic polymer flocculants.

How to use polymers for sludge dewatering?

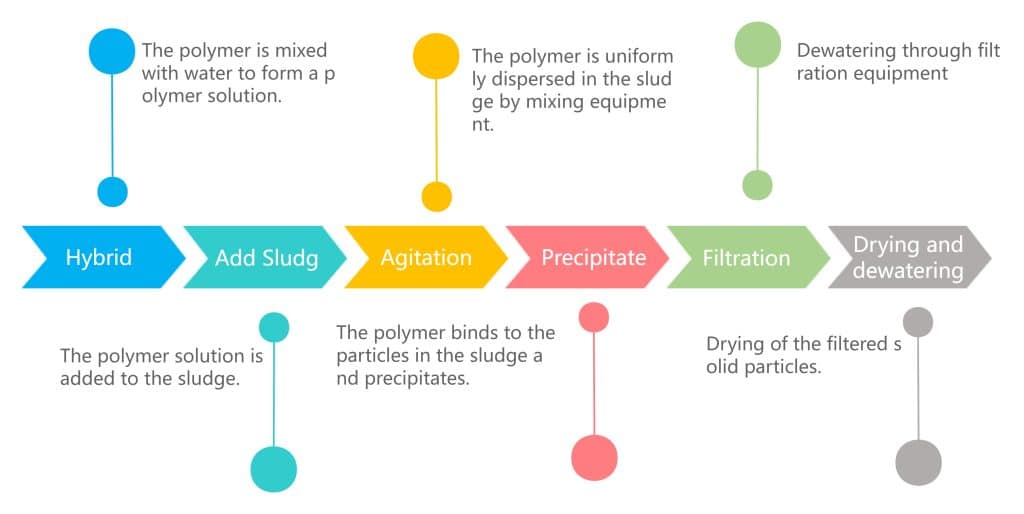

- Preparation: Prepare the required polymer powder or liquid and the necessary equipment and tools. Ensure that the dewatering equipment is in proper working order and that the treatment area is cleaned.

- Mixing the polymer solution: Prepare the polymer solution to a certain concentration by mixing the polymer powder or liquid with an appropriate amount of water according to a predetermined formula. Mixing equipment or mixing tanks can be used to mix the solution adequately.

- Dosing System Settings: Adjust the settings of the dosing system to ensure that the polymer solution is added to the sludge at the proper rate and proportion.

- Dosing Polymer Solution: Add the formulated polymer solution to the sludge to be treated through the dosing pump to ensure that the polymer solution covers the surface of the sludge evenly.

- Stirring and mixing: Use stirring equipment or agitator to stir and mix the sludge with the polymer solution thoroughly to ensure that the polymer is in full contact with and mixed with the sludge particles. The duration and intensity of agitation can be adjusted as needed.

- Stationary reaction: The mixed sludge is left to stand for some time to allow the polymer to interact and react with the particles in the sludge. During the standing process, the polymer will combine with the sludge particles to form larger agglomerates, which helps to improve the solid-liquid separation efficiency.

- Solid-liquid separation treatment: The treated sludge will be sent to dewatering equipment for solid-liquid separation treatment, such as filter presses, centrifuges or screw presses. The dewatering equipment will remove the water in the sludge quickly, thus realizing the dewatering and reduction treatment of sludge.

Summary

Sludge dewatering polymers play an irreplaceable role in the field of wastewater treatment. By using these specialized polymers, wastewater treatment plants can achieve a more efficient, economical and environmentally friendly sludge treatment process.

With over 16 years of experience in wastewater treatment, KUOSI has grown to become a leading water treatment manufacturer in China and a one-stop shop for customers worldwide. Covering a range of products, offering filter presses, air flotation machines, paddle dryers, roots blower, disinfection systems and wastewater screens for treating wastewater, visit the official website homepage to contact us for your service!