Sodium hypochlorite is a proven, cost-effective, reliable, and safe alternative disinfection treatment. On-site generated sodium hypochlorite is stable and easy to feed, and less chlorine is lost to the atmosphere due to better mixing and retention in treated water.

Definition Of Sodium Hypochlorite Generator

Sodium hypochlorite generator is a kind of water treatment disinfection and sterilization equipment, which takes saline water as raw material and generates sodium hypochlorite solution through electrolysis reaction. Sodium hypochlorite is a kind of chlorine-containing compound, which is usually used as a disinfectant and bleach.

Applications Of Sodium Hypochlorite Generators

Sodium hypochlorite generators are mainly used in the field of water treatment, especially in water and wastewater treatment plants. Some of the major applications of sodium hypochlorite generators are listed below:

- Water disinfection: Sodium hypochlorite generator is widely used in the disinfection process of drinking water and industrial water. It effectively kills bacteria, viruses and other microorganisms in the water and ensures that the water quality meets hygiene standards.

- Wastewater treatment: In wastewater treatment plants, sodium hypochlorite generators can be used to disinfect treated wastewater to prevent re-release into the environment causing pollution in water bodies.

- Swimming pool disinfection: Sodium hypochlorite generator is also commonly used in swimming pool water disinfection to keep the water quality of swimming pool clean and hygienic.

- Industrial uses: In some industrial processes, sodium hypochlorite generators can be used to disinfect industrial wastewater to ensure that the discharged wastewater does not cause harm to the environment.

- Agricultural irrigation: In some agricultural practices, sodium hypochlorite generators can be used to disinfect farm irrigation water, helping to prevent the spread of pathogens.

- Food Processing: In the food and beverage industry, sodium hypochlorite generators can also be used to disinfect water in production and food processing.

Advantages and Disadvantages of Sodium Hypochlorite Generator

| Advantages | Disadvantages |

| Highly effective disinfectant | Produces relatively low concentrations of hypochlorite, requiring additional concentration treatment |

| Continuous generation of sodium hypochlorite possible | Equipment and operating costs may be high for large-scale industrial applications |

| No need to store or transport hazardous gases | Operation and maintenance may require specialized knowledge |

| Relatively safe, no need to store strong oxidizers | Some equipment may be affected by salinization and fouling |

| Adjustable output and concentration | Requires electrical power supply and risk of power outages |

| Suitable for a wide range of applications | Wastewater and by-products need to be addressed |

Disinfection Needs In Wastewater

The main reasons why water needs to be disinfected in wastewater treatment include the following:

- Microbial control: Wastewater may contain a large number of microorganisms, including bacteria, viruses, and parasites. These microorganisms may pose a threat to the water environment and human health. Through the disinfection process, the growth of these microorganisms can be effectively killed or inhibited, preventing the water body from spreading diseases.

- Preventing secondary Contamination of Water: Treated wastewater is usually discharged into water bodies for irrigation or other purposes. If the microorganisms in wastewater are not effectively controlled, it may lead to secondary contamination of water sources, affecting the environment and human water safety.

- Protection of water ecosystems: Microorganisms and hazardous substances in wastewater may cause harm to water ecosystems, affecting the survival and reproduction of plants and animals in the water. Disinfection can reduce these negative impacts on water ecosystems.

- Compliance with environmental regulations: Disinfection is one of the legal requirements for wastewater discharge in many countries and regions. Complying with regulations and disinfecting wastewater as necessary is a legal responsibility to maintain environmental health and human health.

- Improving water quality: Disinfection can effectively remove odors from wastewater and improve the appearance of water quality. This is essential for safeguarding the quality of water and enhancing the living environment of residents.

How does a sodium hypochlorite generator disinfect?

The process of operating a sodium chlorate generator in a wastewater treatment plant involves converting common salt (sodium chloride) into sodium hypochlorite, an effective disinfectant.

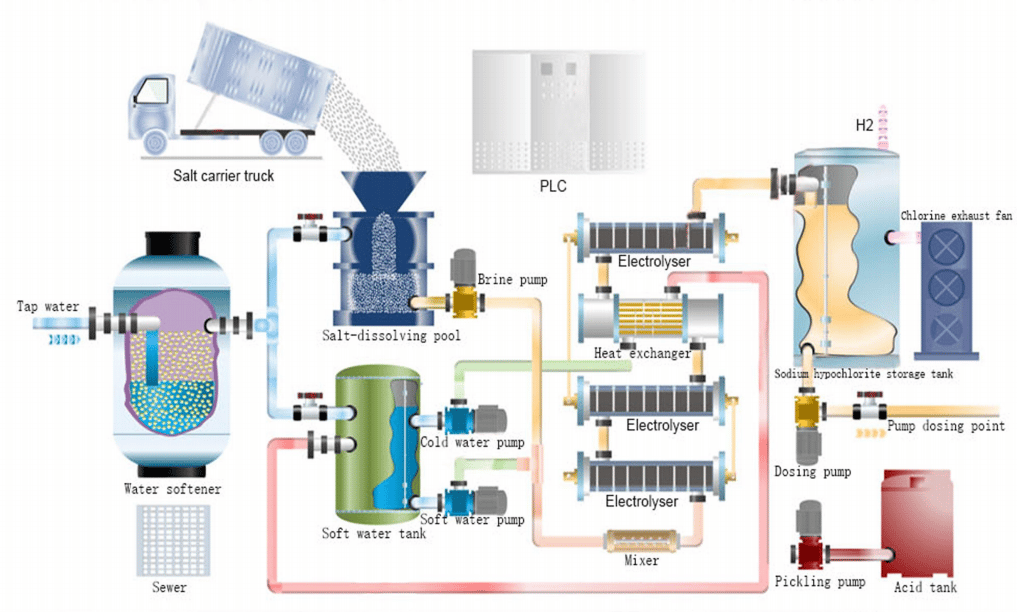

Firstly, tap water is softened to remove calcium and magnesium ions from the water, and part of the softened water provides the dilution water for the sodium feed; secondly, the other part flows into the dissolving salt tank, where the refined salt is dissolved into a 30% saturated brine, which is softened by a metering pump and mixed accurately with the dilution water, and then enters the power plant under the action of the electrolysis tank to carry out the direct current electrolysis. The prototype in the cell produces chlorine gas and the cathode produces sodium hydroxide and hydrogen gas. The two products react to produce a sodium hypochlorite solution.

Anodic reaction: 2Cl- – 2e- → Cl2 (oxidation reaction)

Cathode reaction: 2Na+ + 2e + 2H2O → 2NaOH + H2↑ (reduction reaction)

Total reaction equation: NaCl + H2O → NaClO + H2↑

Adjustment of Concentration: The generated sodium hypochlorite solution may need to be further processed and adjusted to ensure that the concentration is suitable for the disinfection requirements of the wastewater.

Addition to Wastewater: An adjusted concentration of sodium hypochlorite solution is added to the wastewater for disinfection. During this process, sodium hypochlorite releases chlorine ions, which have the effect of killing or inhibiting microorganisms.

Monitoring and control: Wastewater treatment processes often require close monitoring of the sodium hypochlorite dosage to ensure that the desired disinfection is achieved. Automatic control systems are often used to adjust the dosage rate to accommodate changes in wastewater quality.

Comparison of three wastewater disinfection methods

Sodium Hypochlorite Disinfection

- Principle: Sodium hypochlorite (NaClO) is a chlorine-containing disinfectant that kills or inhibits the growth of microorganisms by releasing chloride ions. It is an effective oxidizing agent with a wide germicidal spectrum.

- Advantages: Sodium hypochlorite is easy to operate, widely used in the field of water treatment, and can kill a variety of microorganisms.

- Disadvantages: There is a potential for chlorine by-products such as chloric acid and chloramines. In addition, prolonged use may result in resistance to microorganisms.

Ozone Sterilization

- Principle: The ozone (O₃) in the ozone generator is a strong oxidant, and the oxygen molecules are highly active, which can destroy the cell walls and cell membranes of microorganisms, thus realizing the sterilization effect.

- Advantages: Ozone can effectively remove organic matter, color and odor, some difficult to degrade the pollutants have a better oxidation effect.

- Disadvantages: Ozone treatment system is relatively complex, operation and maintenance costs are high, and the stability of ozone is poor, need to generate and use on-site.

UV Sterilization

- Principle: Ultraviolet light (UV-C) can destroy the nucleic acid of microorganisms and prevent them from reproducing, so as to achieve the effect of sterilization.UV-C can penetrate the cell wall and cell membrane of microorganisms and directly destroy their genetic material.

- Advantages: UV disinfection does not require the addition of chemicals, does not produce by-products, and has no impact on water quality. It is relatively easy to operate and has no chemical residue.

- Disadvantages: UV penetration is relatively weak, need to ensure that there is no turbidity in the water body to block UV.

The choice of sodium hypochlorite, ozone or UV disinfection method usually depends on factors such as the nature of the water body, the target disinfection effect, and the operating and maintenance costs. In practice, a combination of different disinfection methods may also be used to achieve more comprehensive water quality treatment.

How to maintain the sodium hypochlorite generator?

Maintaining your sodium hypochlorite generator is key to ensuring its efficient operation over time. Here are some common ways to maintain a sodium hypochlorite generator:

- Periodic cleaning and inspection of the electrolytic cell: The electrolytic cell is the core component of the sodium hypochlorite generator and needs to be cleaned periodically to prevent deposits from accumulating on the surface of the electrodes. Also, monitor and check the wear and tear of the electrode potential to ensure proper electrode operation.

- Control salt and water quality: Ensure that the salt concentration and water quality in the electrolyte are maintained in the proper range to prevent crystallization, corrosion, or other problems.

- Maintain the cooling system: If the sodium hypochlorite generator utilizes a cooling system, ensure that the cooling water is smooth and clean to prevent clogging or overheating of the cooling system.

- Check the piping and valves: Regularly check the water supply piping, electrolyzer, and related valves to make sure they are not leaking, clogged, or corroded.

- Keep the operating environment clean: Make sure the environment around the sodium hypochlorite generator is dry and clean to prevent dust and impurities from entering the equipment.

Summary

Sodium hypochlorite generator is a device used for water treatment and disinfection, the core principle of which is to produce sodium hypochlorite through electrolysis of a salt solution. Sodium hypochlorite generators have unique advantages over disinfection methods such as ozone and ultraviolet light.

KUOSI offers wastewater treatment equipment such as filter presses, screw presses, paddle dryers, dissolved air flotation systems, roots blowers, dosing systems. Feel free to contact us.