Scrubber water treatment is essential in managing wastewater generated from air pollution control systems, especially wet scrubbers. These systems are used to capture and neutralize harmful gases, particles, and chemicals from industrial exhaust, but they also produce contaminated water as a byproduct. Proper treatment of this scrubber wastewater is crucial to prevent pollutants like heavy metals, acids, and particulate matter from entering natural water bodies.

What is a scrubber?

A scrubber is a device used to remove pollutants from exhaust gases in a wide range of applications such as industrial discharges, marine emission control, and wastewater treatment plants. It reduces the amount of pollutants emitted into the environment by contacting with a liquid, usually water or lye, so that harmful substances in the exhaust gas are absorbed or neutralised.

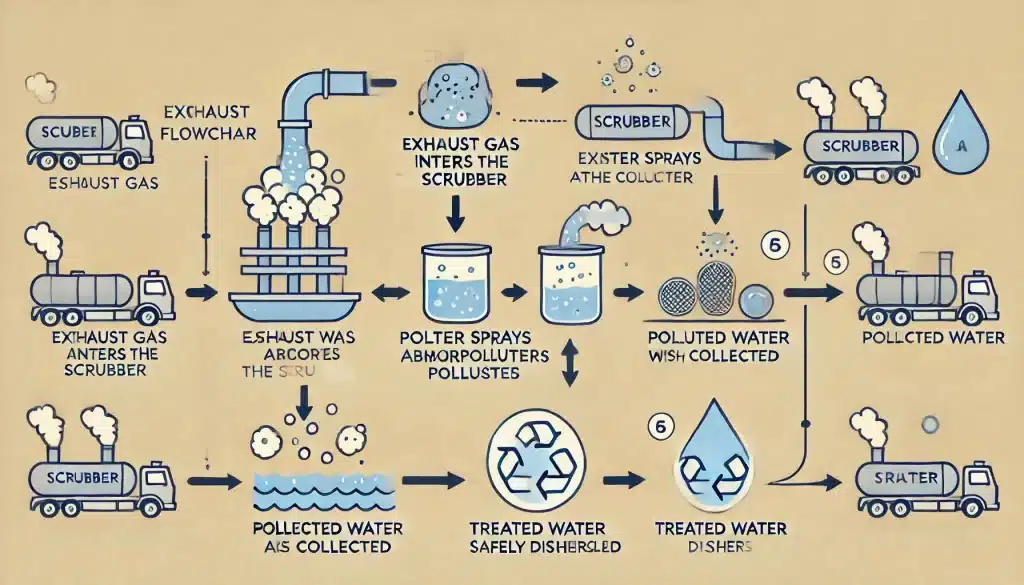

Working Principle

The basic principle of a scrubber is that the exhaust gas is sprayed or exposed to a liquid to capture pollutants in the gas. These pollutants are dissolved, chemically reacted or adsorbed in the liquid, and the concentration of pollutants is substantially reduced when the exhaust gas exits the scrubber. Depending on the nature of the pollutants in the exhaust gas, different types of scrubbing liquids can be selected.

Why scrubber water treatment?

Sulphides: Sulphates and sulphites formed from SOₓ.

Heavy metals: Such as mercury, lead and arsenic.

Particulate matter: Such as soot, dust and other tiny particles.

Organic compounds: Volatile organic compounds (VOCs) and hydrocarbons.

The discharge of untreated washing wastewater into the environment may cause harm to aquatic organisms and violate environmental regulations. Therefore, it must be properly treated before it is discharged or reused.

Main Steps In Scrubber Water Treatment

Solid-Liquid Separation

Purpose: To de-blow large suspended particles and solid pollutants from wastewater for solid-liquid separation.

- Sedimentation: Allowing solids to settle in clarifiers or settling tanks.

- Filtration: Use sand filters or membrane filters to capture fine particles.

- Centrifugation: Separating density-based solids through a centrifugal screw machine.

pH Adjustment

Purpose: To adjust the pH of the wastewater to ensure that the wastewater is neutral and to prevent corrosion and failure of reactions in subsequent treatments.

- Acid addition: If the water is too alkaline, an acid such as sulphuric acid can be added.

- Alkali addition: If the water is too acidic, lime or caustic soda can be added.

Metal Removal

Purpose: To remove toxic heavy metals and prevent pollution of the environment.

- Chemical precipitation: Adding chemicals (e.g. sulphides, hydroxides) to cause heavy metals to form insoluble compounds for precipitation.

- Ion exchange: Use resin to exchange harmful metal ions.

- Adsorption: Use activated carbon or special adsorption materials to remove heavy metals.

Sulphide Removal

Purpose: To remove sulphides from wastewater to prevent them from producing odours and polluting the environment.

Chemical oxidation method: Add oxidants (such as sodium hypochlorite, hydrogen peroxide) to oxidise sulphide into harmless sulphate ions.

Aeration oxidation method: Increase the oxygen content through the aeration of the air flotation system to oxidise the sulfide under the action of oxygen.

Biological Treatment

Aim: To use microorganisms to degrade organic compounds.

- Aerobic treatment: Decomposition of organic matter under aerobic conditions using bacteria.

- Anaerobic treatment: Decomposition under anaerobic conditions to produce biogas.

Final Filtration and Sterilisation

Purpose: To remove remaining fine particles and pathogenic microorganisms.

- Microfiltration/Ultrafiltration: Use of membranes to remove fine particles.

- Disinfection: Use of chlorine, UV or ozone generators to kill microorganisms.

Sludge Treatment and Dispos

Purpose: To treat solids collected during the treatment process.

Thickening and dewatering: Further dewatering by methods such as kuosi filter press or paddle dryer to reduce sludge volume.

Stabilisation: Treatment of sludge to reduce odours and pathogens.

Disposal or utilisation: Landfill, sludge incineration or use in construction materials.

Scrubber water treatment is an important environmental management practice in industries that use scrubber towers to control air emissions. An effective treatment process ensures that pollutants transferred from air to water do not harm the environment.

The Benefits of Scrubber Water Treatment

- Environmental protection: removes pollutants and prevents harmful substances from entering the water body, protecting the environment.

- Compliance: Ensure wastewater meets discharge standards, avoiding legal liability.

- Extend equipment life: Reduce corrosive substances, protect equipment and reduce maintenance costs.

- Resource saving: Treated water can be recycled, reducing the consumption of fresh water.

Open and Closed Loop Scrubbers

Open-loop scrubbers and closed-loop scrubbers are two different types of exhaust gas scrubbing systems used primarily for the desulphurisation of exhaust gases in ships and industrial facilities to reduce emissions of pollutants such as sulphur oxides (SOx).

Open-Loop Scrubber

Working Principle:

The Open-Loop Scrubber uses the natural alkalinity of seawater to neutralise sulphur oxides in the exhaust gas. The exhaust gas is cooled by spraying seawater, and SOx reacts with the alkaline substances in seawater to form soluble substances such as sulphates.

Wastewater treatment:

The treated seawater is discharged directly back into the ocean, so there is no need for a complex wastewater recycling system.

Applicable Scenario:

Suitable for use in oceanic areas, as direct discharge of seawater may be restricted in some coastal areas or harbours.

Closed-Loop Scrubber

Working Principle:

Closed-Loop Scrubbers use an alkaline chemical liquid (e.g. sodium carbonate solution) rather than seawater to neutralise sulphur oxides in the exhaust gas. The exhaust gas is sprayed through the alkaline solution to convert the SOx to sulphate.

Wastewater treatment:

Wastewater is treated and recycled. Sludge or residue from the treatment process needs to be discharged and treated regularly to avoid polluting water bodies by direct discharge.

Applicable Scenarios:

Suitable for use in waters close to the coast or with high environmental requirements, as no direct discharge of sewage.

What scrubbers are more suitable for wastewater treatment plants?

In wastewater treatment plants, closed-loop scrubber towers are usually used because they are more suitable for situations where environmental protection is more demanding, especially in areas where direct discharge of wastewater is not possible. Wastewater treatment plants mainly deal with pollutants in the effluent, often accompanied by odours and volatile pollutants. Closed-loop scrubber towers can absorb and neutralise these pollutants efficiently, while avoiding direct discharge of wastewater and reducing pollution of the surrounding environment.

Summary

In summary, treating scrubber wastewater is an important step in reducing the environmental impact of air pollution control systems. Effective scrubber water treatment not only helps in maintaining clean waterways but also supports the overall goal of sustainable water management.

In the field of water treatment, achieving reliable and efficient water quality monitoring is essential for safeguarding our environment. Kuosi has been at the forefront of this mission for over 17 years. With a strong focus on innovation, Kuosi provides a comprehensive range of high-quality instruments and solutions tailored to various industries, from industrial wastewater management to municipal water treatment. Feel free to contact us for customized water treatment solutions.