Filter presses play a key role as an important solid-liquid separation equipment in the industrial and environmental treatment fields. However, like any complex mechanical device, filter presses may encounter various faults and problems during long operations. To ensure its efficient and stable operation, we need to understand and solve the possible malfunctions.

What’s a filter press?

A filter press is a device used for solid-liquid separation, separating solids from sewage, removing impurities and suspended solids from industrial wastewater. This equipment is usually used in the processing of liquids containing a large number of solid particles, such as sludge, wastewater, chemicals, pharmaceuticals, food processing and other industries. Filter press plays an important role in industrial production and environmental protection.

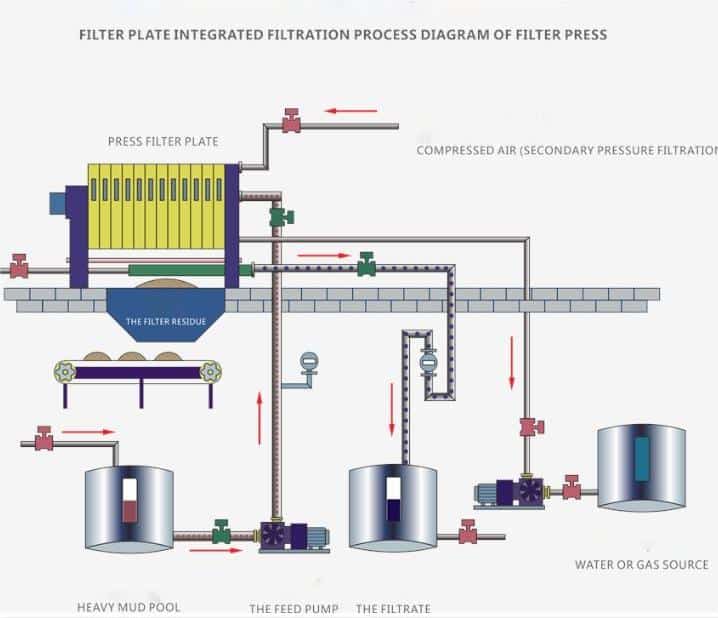

Working Principle of Filter Press

The basic working principle of a filter press is to pass a liquid containing solid particles through a filter medium by applying pressure, separating the solid particles, and obtaining a drier solid material, while the liquid portion is called the filtrate. The main components include the filter press frame, filter plates, filter cloth, and hydraulic system.

Feed: The liquid containing solid particles to be treated is fed into the feed system of the filter press.

Filtration: The feed liquid passes through the filtration area of the filter cloths and plates, where the solid particles are retained on the filter cloths, forming a solid cake, while the filtrate passes through the filter cloths into the discharge system.

Drainage: The filtrate is pressurized by a hydraulic system to drain the system, usually for subsequent processing or recycling.

Discharge: Once the filtration is complete, the filter press can be opened to remove the solid cake formed.

Filter Press Applications

Wastewater treatment: Filter presses are widely used in wastewater treatment plants to treat wastewater containing solid particles. Through the filtration process of the filter press, suspended substances can be effectively separated, reducing the concentration of solids in the wastewater, and at the same time obtaining a relatively dry solid filter cake.

Chemical industry: Chemical production often involves a variety of chemical wastewater trearment, resulting in products that may be liquid-containing solids. Filter presses are used to extract the solids from the products to achieve the effect of separation and purification.

Food and beverage: In the food industry, filter presses are often used to separate suspended solid particles from juices, liquors, etc. to improve the clarity and taste of the liquid.

Pharmaceutical industry: In the pharmaceutical field, filter presses are used for solid-liquid separation and solvent removal to obtain pure drug solid products.

Environmental protection projects: In some environmental protection projects, filter presses are used to treat industrial wastewater, wastewater soilds, etc., to realize the recovery of resources and reduce environmental pollution.

The above are just some typical applications of filter presses in various industries different types of filter presses as well as different models of filter presses can be customized and applied according to specific process requirements and material characteristics.

Advantages And Disadvantages Of Filter Presses

Advantages of Filter Press

- Efficient solid-liquid separation: The filter press can quickly and efficiently separate liquids containing solid particles into solid filter cake and filtrate, which improves the separation efficiency.

- Low water content of the product: By applying pressure, the filter press can obtain a relatively dry solid filter cake with low water content, which is convenient for subsequent processing and transportation.

- Applicable to a wide range of materials: Filter presses are suitable for treating a wide range of materials of different natures, including but not limited to wastewater, mineral slurries, chemicals, food liquids, etc.

- High degree of automation: Some modern filter presses are equipped with automation control systems, which can realize automatic operation and monitoring, reducing the work intensity of operators.

- Flexibility: There are different types of filter presses, such as plate and frame filter presses, membrane types, drum types, etc., and you can choose the right model according to the nature of the material and process requirements.

Disadvantages of Filter Presses

- Higher equipment cost: Especially for some high-specification and high-performance models, the equipment cost is relatively high.

- Maintenance and operation are more complicated: Some filter presses require a high level of technical skill to operate and maintain, including specialized knowledge of the hydraulic system, filter cloth replacement, and so on.

- Relatively limited production capacity: For large-scale production capacity requirements, it may be necessary to invest in larger-sized filter presses, which may increase costs.

- Filter media consumables and limitations on particle size: Filter media such as filter cloths or filter plates in filter presses need to be replaced regularly, which may be less suitable for smaller particles.

Filter Press Common Faults And Solutions

| Common Failures | Causes | Solutions |

| Hydraulic system leakage | Seal damaged – Joint loose | Replace damaged seals – Tighten joints |

| Cloth clogging | Filter cloth wear – Improper operation | Replace the damaged filter cloth – Adjust the operating parameters |

| The hydraulic oil temperature is too high | Insufficient hydraulic oil – Cooling system failure | Refill hydraulic oil – Repair cooling system |

| Pump failure | Pump wear – The pump is faulty | Replace worn pump parts – Repair or replace the pump |

| Filter Cake Shedding | Loose filter cloth – Improper operation | Reinstall the filter cloth – Adjust the operating parameters |

| Electrical system problem | The cable is disconnected – The controller is faulty | Check the cable. – Replace the faulty controller |

| The cake is not formed | The operating parameters are incorrectly set – The filter cloth is worn | Adjust operating parameters – Replace the damaged filter |

How to maintain the filter press?

- Please use a good filter cloth, which must be flat.

- Please check frequently whether all parts of the product are reliable: whether fasteners are fixed; no leakage in the hydraulic system; all transmission parts work smoothly, etc.

- Check the quality of hydraulic oil regularly. The hydraulic system must be kept clean. The oil temperature should not exceed 60℃. Check the oil filter frequently. In winter, please make sure the temperature is above 15℃.

- When using the machine for the first time after replacing the oil hose, keep the high-pressure oil hose closed.

- Whenever you use the machine, please check the working condition. If there is any abnormality, please turn off the machine and have it repaired.

- An insulation test of electrical parts is required once a month.

- The feed pressure, shut-off pressure, and slurry temperature must be strictly controlled below the rated values. The filter press must not be turned on if the following conditions occur; the number of plates is not enough; the maximum distance of the sealing plates is less than the cylinder distance.

- For mechanical filter presses, please pay attention to the closing conditions. Please do not overload the machine for a long time.

- If the machine is not used for a long time, please store it in a dry and ventilated place. The relative humidity is not more than 80% and the temperature is around 0-40℃. The hydraulic system should be filled with oil. Exposed structural surfaces should be coated with anti-rust oil.

- The plates and frames should be kept away from substances that may cause damage, and away from heat sources, rain, sunlight, etc.

- When using a membrane filter press the chamber must be filled with slurry before air extrusion. The compressed air must be discharged in advance before opening the plates. Otherwise, the plates may rupture. When filtering, please pay close attention to the air pipe, if there is any abnormality, please close the air inlet valve and discharge the air. It can be used again after repair.

Summary

Troubleshooting and maintenance of filter presses is critical to not only improve the life of the equipment, but also to ensure its efficient operation to meet the needs of different fields for solid-liquid separation. Through regular inspection, maintenance and proper operation, we can better prevent potential problems from occurring, minimize downtime and increase productivity.

KUOSI, your trusted China filter press manufacturer and supplier, is dedicated to manufacturing a wide range of industrial sludge filter press, sludge dryer, screw press, dosing system and wastewater screen and accessories. We are a professional filtration team, contact us for engineered filtration solutions for your industry to help you achieve your production goals with ease.