As urbanization accelerates and pressure on water resources increases, wastewater treatment is no longer just about “purifying water”, it is also a process of resource recovery. In this process, “biosolids”, a by-product of sludge treatment, is becoming a sustainable fertilizer solution for agriculture.

What are biosolids?

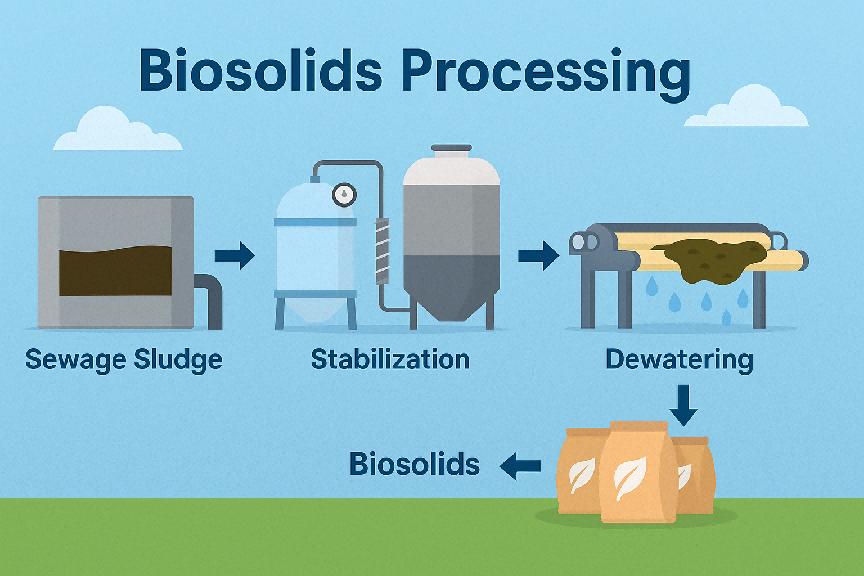

Biosolids are stabilized and treated sludge residues that are rich in organic matter, nitrogen, phosphorus and trace elements. Through processes such as anaerobic digestion, thermal hydrolysis (THP), and mechanical dewatering, sludge can be converted into harmless, controlled fertilizer material.

Advantages of Biosolids Fertilizer

- Nutrient-rich: Contains nitrogen, phosphorus, potassium and other essential elements for plant growth, and exists in the form of slow-release, with long-lasting fertilizer effect;

- Improve soil structure: Improve soil organic matter, enhance water and fertilizer retention capacity;

- Resource reuse: Turning “waste” into “fertilizer”, reducing dependence on chemical fertilizers;

- Carbon reduction contribution: Reduces greenhouse gas emissions by reducing landfill incineration;

- Contribute to carbon reduction: Reduce greenhouse gas emissions by reducing landfill incineration.

- Controllable costs: An economically viable alternative to fertilizers for farmers and municipalities.

Biosolids Process Flow

Initial Sludge Treatment Phase

The whole process starts with thickening of the sludge. Through gravity belt, rotary drum or air flotation thickening techniques, sludge volume and water content can be significantly reduced. Subsequent stabilization – such as anaerobic or aerobic digestion – not only reduces pathogens and odors in the sludge, but also converts some of the organic matter into energy sources such as methane.

Deep Dehydration And Heat Treatment

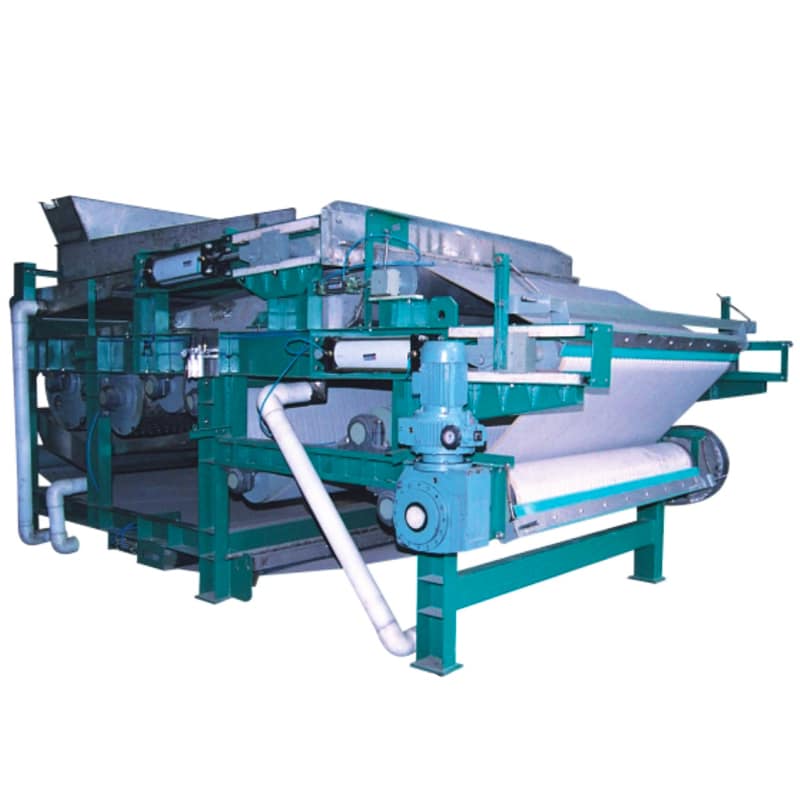

In order to further reduce the volume and facilitate subsequent utilization, the sludge needs to be dewatered, and Kuosi offers belt filter presses, screw press dewaterers and Decanter Centrifuges that can increase the solids content of the sludge to 15-25%.

Thermal Hydrolysis (THP) can also be incorporated before and after dewatering. This technology destroys the sludge cell structure under high temperature (160~180°C) and high pressure, effectively releases organic matter, improves the efficiency of anaerobic gas production, and enhances the dewatering effect at the same time. The treated sludge has a denser texture and low temperature dludge dryer, making it more suitable for energy recovery or agricultural utilization.

Further drying is carried out by low temperature belt drying or paddle drying equipment, which increases the solid content to over 80%, making it easy for storage, transportation and subsequent processing.

Resource Utilization Pathways

The processed biosolids have a wide range of application potentials. One is agricultural use, after composting or granulation, it can be used as organic fertilizer in farmland, woodland and urban greening. The second is energy recovery, through anaerobic digestion to produce biogas for heat or power generation, or sludge incineration, pyrolysis treatment into heat or gas. In addition, there is also cutting-edge exploration of biosolids as part of the composition of building materials, developed into eco-bricks, cement substitutes and so on.

Meeting Standards and Ensuring Safety

- U.S. EPA 503 regulation (Class A/B Biosolids)

- EU Sludge Land Use Directive

- China GB/T 24600 Standard for Disposal of Sludge from Municipal Sewage Treatment Plants

Summary

Sludge is not the same as garbage. Empowered by technology, it is a resource worth exploiting.

Kuosi is looking forward to providing safe, efficient and environmentally friendly sludge recycling solutions for municipal, industrial and agricultural users through its professional machinery and heat treatment equipment. We provide pre-treatment integrated sludge scraper for treating sewage sludge, dosing system for treatment process, SBR floating decanter, aeration blower, DAF system, grit removal equipment and wastewater screen, want to turn sludge into treasure, welcome to contact our professional team to customize the most suitable solution for you.