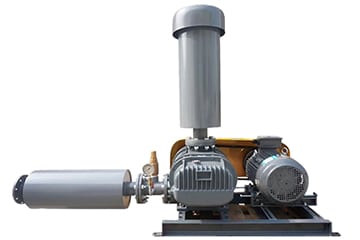

Aeration Blower

Aeration blowers are of great interest to engineers, suppliers and end users. 45% of wastewater treatment plants use electricity for aeration, and blowers account for more than 55% of the energy used by a typical wastewater treatment plant (WWTP). The right choice of aeration blowers is arguably one of the most important considerations for wastewater treatment plants, as they contribute positively to total cost of ownership, conditioning capacity, maintenance requirements and efficiency – they can improve by up to 25%.

The air supplied by the blower to the aeration basin has several functions. The first is to provide the oxygen needed to metabolize the organic compounds in the wastewater. These organic compounds are called “BOD 5” (biochemical oxygen demand), named after the 5-day test used to measure the concentration of these compounds. Oxygen must be dissolved in the wastewater in order to be used by microorganisms. Diffusers use tiny bubbles to efficiently dissolve oxygen into the wastewater.

When microorganisms convert ammonia (NH 3 ) to nitrate (NO 3 ), additional oxygen is required, a process called nitrification. Nitrification usually accounts for half of the overall process oxygen demand.

The combination of sludge and wastewater in the aeration tank is called the mix. The air provided by the blower creates turbulence in the mix to keep the sludge in suspension. Mixing also keeps the contents of the aeration tank uniform. In many plants, mixing limitations rather than oxygen demand determine the minimum air flow rate.

Most diffusers have an upper limit on air flow to prevent physical damage. Maximum flow rates vary by diffuser design.

KUOSI is a manufacturer and supplier of aeration blowers, please contact us for quotation.

Notes on aeration blower systems

Different facilities have different priorities and needs for their aeration systems, and it can be difficult to know what factors to consider. Here are some things to keep in mind.

- Technology type (roots, screw, cam, multi-stage, turbine, etc.)

- Remote monitoring and connection capabilities

- Energy efficiency and efficiency requirements

- Service and maintenance requirements

- Total life cycle cost

- Noise levels

- Equipment footprint

- Ease of installation

- Plant location and climate

Blowers for wastewater aeration are part of a complex treatment system. The air requirements of the process are constantly changing. Providing a blower that operates at a single flow rate and discharge pressure is unlikely to meet system requirements.

A good design will include consideration of variable process demands, current and future loads, and the impact of environmental conditions on performance. The final specification should define the range of operations that must be covered by the blower system.

Water & waste water applications

- Anaerobic digestion

- Activated sludge method

- Diffusion noise

- Lagoon noise

- Membrane bioreactor

- Sequential batch reactor (SBR)

- Moving bed biofilm reactor

- Filter backwashing

- Biogas

- Sedimentation tank aeration