In the field of sludge dewatering, volute dewatering presses stand out thanks to their innovative design and efficient performance. Designed to efficiently separate solids from liquids, this equipment is an indispensable tool in a wide range of industries.

What Is A Vortex Dewatering Press?

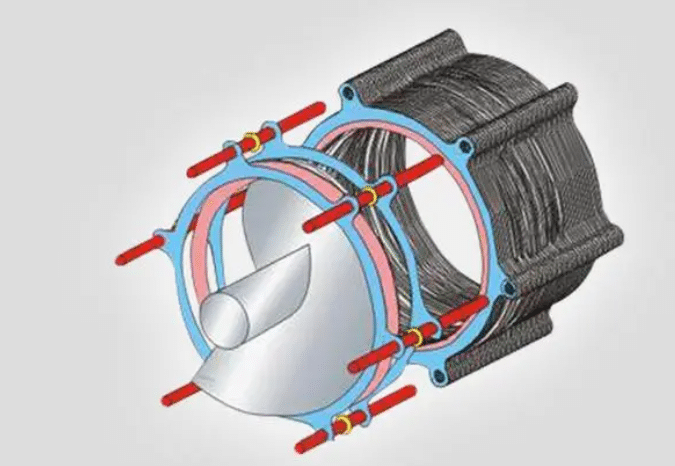

Vortex dewatering press is a kind of efficient sludge dewatering equipment, which utilizes its unique snail shell shape design to gradually compress the sludge and squeeze out the liquid, thus realizing the separation of solids and liquids. It is widely used in municipal sewage treatment, industrial wastewater treatment and septic tank sludge treatment. Compared with traditional equipment, the vortex dewatering press is more energy efficient, simple to maintain and covers a small area.

Design Features of Vortex Dewatering Presses

The design of the vortex dewatering press with a worm shell is based on the following principles:

- Spiral compression: The spiral design progressively compresses the sludge and squeezes out the liquid.

- Progressive pressurization: The shape of the contracted worm shell progressively pressurizes the sludge to improve dewatering efficiency.

- Fluid optimization: Carefully designed flow paths reduce resistance and increase capacity.

- Uniform pressing: Ensures uniform pressure on the sludge to prevent clogging.

Volute Dewatering Press vs Screw Dewatering Press

| Feature | Volute dewatering Press | Screw dewatering press |

| Design principle | Volute shape gradually compresses sludge, squeezing out liquid through a spiral | Spiral blades rotate to compress and squeeze out liquid from sludge |

| Dewatering process | Gradual pressure increase with volute shrinkage for efficient dewatering | Continuous rotation of spiral blades to compress and dewater sludge |

| Advantages | – Self-cleaning function reduces maintenance needs – Energy-efficient – Compact design saves space | – Versatile, handles various sludge types – Simple structure, easier maintenance – High processing capacity |

| Disadvantages | – Moderate processing capacity, suitable for small to medium scale | – Frequent maintenance – Larger footprint compared to volute dewatering press |

| Maintenance frequency | Low, self-cleaning reduces manual intervention | Higher, requires regular inspection and cleaning |

| Processing capacity | Small to medium scale | Large scale |

| Footprint | Small, compact design | Large, requires more space compared to volute press |

| Energy efficiency | High, optimized design reduces energy consumption | May consume more energy when handling high solid content |

Are Volute Dewatering Press Repairs Any Different Than Other Traditional?

Self-cleaning mechanism

- Vortex dewatering press: Equipped with a self-cleaning feature that automatically cleans sludge buildup inside the unit, reducing the need to rely on manual cleaning. This design helps to maintain efficient operation and extend the life of the machine.

- Traditional dewaterers: Usually require regular manual cleaning to remove sludge buildup, making maintenance more tedious and frequent.

The self-cleaning feature of the vortex dewatering press is mainly achieved through the following methods:

- Rotating brushes or scrapers: Automatically removes sludge from the inside of the shell while the machine is running, preventing buildup and clogging.

- High-pressure water washing: Use high-pressure water flow to wash the inside of the machine to remove sludge and impurities.

- Automatic drainage system: Automatically removes accumulated sludge to prevent deposits.

- Intelligent control system: Automatically monitors and initiates the cleaning cycle to optimize the cleaning process.

Application Areas of Vortex Dewatering Presses

- Municipal wastewater treatment: Handling sludge from municipal wastewater plants.

- Industrial wastewater treatment: applicable to food processing, chemical manufacturing and other industries.

- Septic tank sludge: efficient treatment of septic tank sludge, simplify the treatment process.

Summary

The vortex dewatering press represents an advancement in sludge dewatering technology. Their innovative design, energy-saving features and low maintenance requirements make them ideal for use in municipal wastewater treatment, industrial wastewater treatment and septic tank sludge treatment. Vortex dewatering presses offer an optimized solution for all types of sludge treatment due to their reliability and cost-effectiveness.

KUOSI offers a wide range of advanced and complete sludge treatment equipment, covering a variety of products such as sludge dewatering equipment, sludge dryers, wastewater screens, sludge conveyors, aeration blowers, disinfection systems, dosing systems and mud scrapers. Our equipment is known for its high efficiency, reliability and intelligence to meet different sludge treatment needs. If you need to optimize your wastewater treatment process, please feel free to contact us and KUOSI will provide you with the best solution.