Feed water treatment is the essential process of purifying and conditioning water before it is introduced into industrial systems, such as boilers, cooling towers, or reverse osmosis (RO) systems. The goal of feed water treatment is to ensure the water meets the required quality standards for the specific application, preventing equipment damage and improving operational efficiency.

Basic Concepts of Feed Water Treatment

Feed water treatment refers to a series of treatments to remove impurities, contaminants, and harmful components from water before it enters an industrial system to ensure that the water quality meets the standards required by the equipment. Whether the water is in a potable water supply, a steam boiler, or used as a source for cooling systems, feed water treatment is critical. Water that is not properly treated can lead to equipment corrosion, scaling, and even reduced efficiency, affecting the production process.

Purpose of Feed Water Treatment

- Prevent equipment damage: Remove hardness (e.g., calcium, magnesium) and dissolved gases (e.g., oxygen, carbon dioxide) from the water, preventing scaling and corrosion and extending equipment life.

- Improve efficiency: Ensure that the water quality is suitable for the equipment, improve the thermal efficiency and cooling effect of the system, and reduce energy loss.

- Ensure product quality: In the food, chemical, pharmaceutical and other industries, water quality directly affects the production process and product quality. Through water treatment, ensure that the water source meets the standard.

- Reduce maintenance costs: Reduce equipment failures caused by water quality problems, reduce the frequency of repairs, and reduce operation and maintenance costs.

- Protect the environment: Remove harmful substances from the water, ensure that the discharged water meets environmental standards, and reduce pollution.

- Save water: Reduce the need for fresh water by recycling and reusing the water source and increase the efficiency of water utilization.

Feed Water Treatment Applications

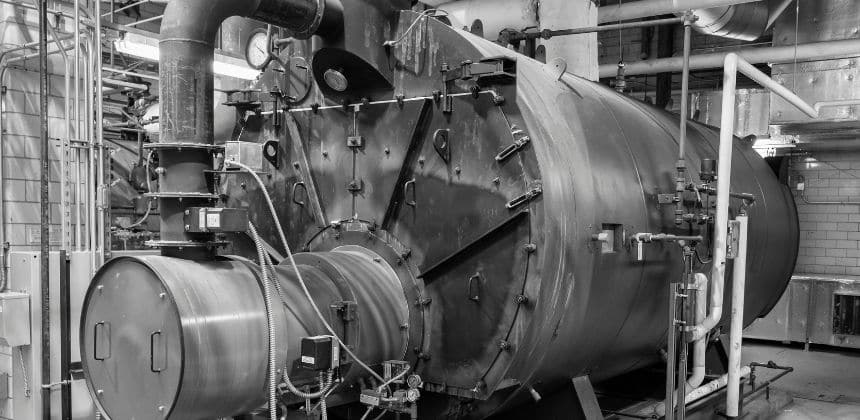

Boiler Systems

Background: Steam boilers are used to generate steam in industries such as power generation, chemical processes, food processing, etc. The boilers require a clean water source to operate properly. Boilers require a clean water supply to operate properly.

Need for feed water treatment: Excessive amounts of minerals (e.g. calcium, magnesium) in the boiler feed water can lead to scaling, reduced thermal efficiency, and possibly even damage to the boiler piping. To avoid this, feed water treatment is required through softening, degassing and reverse osmosis.

Cooling Systems

Application background: Cooling towers and cooling systems typically use water to carry away heat generated by equipment. They are widely used in power plants, petroleum refineries, chemical plants and other industries.

The need for feed water treatment: Cooling water that contains impurities, suspended solids or microorganisms can lead to scaling, corrosion, clogging of pipes, reduced cooling efficiency and increased equipment maintenance costs. Therefore, cooling water needs to be filtered, dechlorinated and degassed.

RO Systems

Application background: Reverse osmosis systems are widely used for water desalination and removal of harmful substances, such as desalination and industrial water treatment.

Necessity of feed water treatment: RO systems require very good quality feed water, as impurities in the water may damage the membrane module or reduce its service life. Before entering the RO system, the water usually undergoes pre-treatment such as softening, filtration and de-oxygenation to protect the reverse osmosis membrane.

Food & Beverage Industry

Background: Water is used as an ingredient in the food and beverage production process or for cleaning, cooling and many other purposes. For example, in the production of beer, mineral water and beverages, the quality of the water directly affects the safety and taste of the product.

Necessity of feed water treatment: To ensure that the water quality meets drinking water standards, the water source usually undergoes stringent treatment, such as disinfection, removal of hazardous substances, adjustment of the pH value, and so on.

Pharmaceutical Industry

Application background: The pharmaceutical industry has extremely strict requirements for water quality, as water is directly related to the drug production process and must be kept free of pollution and impurities.

Necessity of water treatment: In order to ensure that the production water meets the pharmaceutical standards, it is usually required to go through reverse osmosis, deionization, deoxygenation and other advanced water treatment processes.

Power Generation

Background: Power plants often use water to cool equipment and generate steam, especially in thermal and nuclear power plants, where water quality is critical.

Need for feed water treatment: Feed water that contains high concentrations of minerals or hazardous substances can lead to scaling and corrosion of cooling towers, boilers and other equipment, which can reduce power generation efficiency and increase maintenance costs. Therefore, feed water needs to be treated for softening, removal of dissolved gases, and removal of minerals.

Industrial Cleaning

Background: In industrial cleaning, water is often used to clean machinery, equipment, pipelines, etc. Minerals and contaminants in the water may be present in the water. Minerals and contaminants in the water may leave scale or damage the equipment.

Feed water treatment needs: cleaning water usually need to be softened and filtered to ensure that the water quality meets the standards for equipment cleaning and to avoid unnecessary scale or corrosion.

Chemical Industry

Application background: In the chemical industry, water is often used as a solvent, reaction medium, coolant and so on. High quality water is a prerequisite for production safety and efficiency.

Necessity of water treatment: Some chemical reactions require very strict water quality, any impurities or contaminants may interfere with the reaction process or affect product quality. Therefore, water usually needs to be softened, filtered, and treated to remove heavy metals.

Mining Industry

Background: Water is used in the mining process for a variety of purposes such as ore extraction, tailings disposal, etc. Poor water quality may affect the quality of the ore. Poor water quality may affect the ore recovery rate or pollute the surrounding environment.

Necessity of feed water treatment: Mining water needs to be softened, precipitated, filtered, etc. to remove impurities, suspended solids, heavy metals, etc. in order to ensure extraction efficiency and reduce environmental pollution.

Pulp and Paper Industry

Background: Paper production uses a lot of water, especially in pulp and paper production, and the quality of the water affects the quality of the paper and production efficiency.

The need for feed water treatment: Water in the paper industry often needs to be de-suspended, pH adjusted, and chlorine and organic matter removed from the water to avoid affecting the process and product quality.

Mineral Processing & Metal Refining

Background: Water is used in mineral extraction and metal refining processes for cooling, rinsing, and ore sorting.

The need for feed water treatment: Impurities, suspended solids and minerals in the water may interfere with the treatment process and affect the extraction efficiency. Therefore, water needs to be pre-treated, such as filtration, softening, and removal of heavy metals.

Summary

The purpose of feed water treatment is to ensure that water quality meets the requirements of industrial applications, to prevent equipment damage, to improve system efficiency, to safeguard production stability, and to reduce maintenance costs. By removing impurities and harmful components from the water, it is possible to extend equipment life, improve product quality, conserve water, and comply with environmental standards, thus ensuring smooth industrial production.

KUOSI offers a wide range of water treatment equipment, including chemical dosing units, to meet your specific needs. Choose KUOSI for a reliable, efficient and cost-effective solution for your wastewater treatment. Contact us today for more information!