In the modern sewage treatment process, sludge treatment is an important link that cannot be ignored. With the increasingly stringent environmental protection standards, “resource utilization of dried sludge” is becoming the focus of the industry.

What is Dried Sludge?

Dried sludge refers to the solid dry matter obtained after dehydration and drying of sludge produced in the sewage treatment process. It is a by-product of sewage treatment and usually contains organic matter, inorganic matter and trace pollutants.

Sludge Generation

- Sludge generation: During the sewage treatment process, solid impurities in the sewage settle to form “sludge“.

- Sludge dehydration: Use centrifuges, belt filter presses, plate and frame filter presses and other equipment to remove moisture.

- Sludge drying: Further use solar energy, hot air, microwaves and other methods to reduce the sludge moisture to below 10-30%, and finally form dried sludge.

How does Dried Sludge Participate in Water Treatment?

- As a substitute for denitrification carbon source

Some properly treated dry sludge is rich in organic matter and can replace external carbon sources such as glucose and sodium acetate in the denitrification reaction, and can be used in the denitrification stage to save operating costs. - Used to adsorb pollutants in sewage

After pyrolysis or carbonization, dry sludge can be converted into “sludge-based activated carbon” with a good porous structure, which can adsorb heavy metals, organic pollutants, etc. in water. - As a matrix material for artificial wetlands

After harmless treatment, dried sludge can be mixed with materials such as gravel and used as a planting bed or filter material filler for wetland systems to improve the purification efficiency of pollutants. - Realize energy closed loop in sewage treatment plants

High calorific value dry sludge (especially thermal drying products) can be used as a heat source or fuel for sludge drying, heating or power generation systems, realizing a closed loop of “source-utilization-reprocessing”.

The Right Sludge Drying Process for Every Application

Solar Drying

- Principle: Use natural light and ventilation to evaporate water.

- Advantages: Low energy consumption and low operating costs.

- Applicable to: Small and medium-sized sewage plants with dry climate and sufficient open space in the plant area.

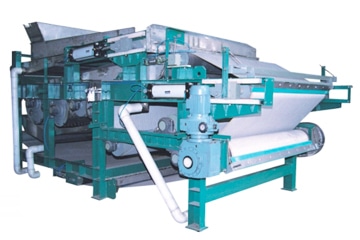

Belt Dryer

- Principle: Sludge transported on a multi-layer mesh belt, hot air drying through the flow.

- Advantages: Continuous operation, small footprint.

- Application: Municipal sewage plants, pre-treatment for fertilizer production.

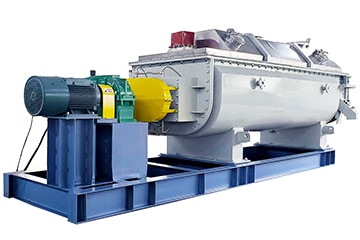

Paddle Dryer

- Principle: Heat transfer + agitation to improve heat transfer efficiency.

- Advantages: Uniform drying, medium energy consumption.

- Application: Industrial or municipal sludge with high solids content.

Fluidized Bed Drying

- Principle: Hot air heats sludge particles in suspension.

- Advantages: Fast drying, suitable for granular sludge.

- Application: With incineration, co-processing in cogeneration plants.

Spray Drying

- Principle: Atomization of sludge, instantaneous drying with high temperature gas.

- Advantages: Fine particles, easy to burn.

- Application: Granulation, sludge fueling.

Vacuum Drying

- Principle: Drying at low pressure with reduced evaporation temperature.

- Advantages: Suitable for heat-sensitive sludge.

- Applicable: Medical waste, special sludge containing pharmaceutical ingredients.

Microwave Drying

- Principle: Direct vaporization of water by microwave internal heating.

- Advantages: Fast heating, precise control.

- Suitable for: Small-scale experiments, high value-added applications.

Summary

Today, as sludge treatment continues to become intelligent and green, choosing the right drying process is only the first step, and a powerful technology platform is needed to truly realize “sludge to resource”. In order to truly realize “sludge into resources”, it also needs the support of a powerful technology platform.

Kuosi, as a digital platform focusing on water treatment and sludge resources, helps companies find the best balance between environmental protection and economy. Whether you are an environmental engineer, an equipment manufacturer or a wastewater plant operator, Kuosi can provide you with efficient, reliable and intelligent sludge treatment, offering sludge dewatering, sludge transportation, dosing systems, DAF systems, aeration blowers, ozone generators, wastewater screens and sludge scrapers, so contact us to drive the industry towards a more sustainable future!