Decontamination involves the removal or reduction of contaminants, harmful chemicals or biohazards from a surface, object or environment. This includes processes that physically clean, neutralize harmful substances, or remove contaminants from a surface or environment.

While Disinfection is a subset of the decontamination process that focuses on killing or inactivating microorganisms such as bacteria, viruses, and fungi. It uses chemicals or other methods to target pathogenic microorganisms for killing in order to reduce the risk of infection or interrupt the spread of disease.

Decontamination

Decontamination focuses on the removal or reduction of contaminants, including chemicals, toxins or radioactive materials, from a surface, object or the environment.

Methods of decontamination

Decontamination is one of the key steps in the water treatment industry and there are many methods that can be used to remove contaminants and impurities from water. Here are some common methods of decontamination:

Physical methods

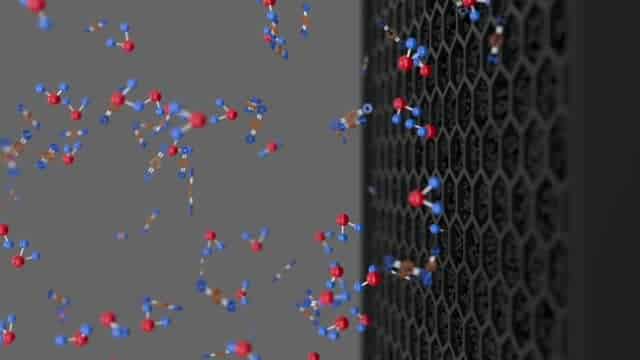

Filtration: The use of a physical barrier to separate solid particles and suspended matter from water.

This is one of the most common methods of decontamination and is suitable for removing solid particles and suspended matter from water. In water treatment, filters are commonly used to remove grit, suspended matter, and sediment. Coarse screen, Sand filters, activated carbon filters and microporous membranes are all common filtration methods.

Sedimentation: The settling of large particulate matter to the bottom by gravity for subsequent removal.

In water treatment, sedimentation is the settling of large particulate matter to the bottom by gravity for subsequent removal. This takes place in a settling tank or sedimentation plant and removes suspended matter, a portion of organic matter, heavy metals, etc.

Chemical methods

Coagulation and flocculation: The use of chemicals to induce the aggregation of small particles into larger clusters for subsequent treatment.

Chemical methods are used to aggregate small particles into larger clusters for subsequent treatment. In water treatment, coagulation and flocculation are often used to remove turbidity, organic matter and colloids.

pH adjustment: Changing the acidity or alkalinity of water to enhance the effectiveness of chemical treatment.

pH adjustment improves the effectiveness of chemical methods such as coagulation and flocculation. In some water treatment processes, the efficiency of removing impurities can be improved by adjusting the pH of the water.

Biological treatment methods

Bioreactor: Utilizes activated sludge microorganisms to degrade organic pollutants and convert them into harmless substances.

In wastewater treatment, bioreactors (e.g., activated sludge systems or biofilters) utilize microorganisms to degrade organic pollutants and convert them into harmless substances.

Adsorption methods

Activated carbon adsorption: The use of activated carbon or other adsorbent materials to remove dissolved organic matter, color and odor substances from water.

Activated carbon adsorption is used in water treatment to remove dissolved organic matter, color and odor substances from water, and is an effective method for removing pollutants that are difficult to treat.

Advanced treatment technology

Reverse osmosis: Removal of minute dissolved contaminants and ions using a semi-permeable membrane.

Reverse osmosis is a highly efficient desalination technique used to remove dissolved inorganic salts and most organic matter from water. It is widely used in drinking water treatment and desalination.

Electrodialysis: Separation of ions from water by driving them through an electric field.

Electrodialysis utilizes the electric field effect to separate ions from water and is suitable for removing specific ions, such as heavy metal ions, and is commonly used in industrial wastewater treatment.

Ultrafiltration: The use of ultrafine pore size membranes to remove tiny particles and bacteria.

Ultrafiltration utilizes ultrafine pore size membranes to remove microscopic particles, bacteria and large organic matter from water. This has applications in both drinking water treatment and wastewater treatment.

Disinfection

Disinfection aims to kill or inactivate pathogenic microorganisms such as bacteria, viruses and fungi, reducing the risk of infection or disease transmission.

Disinfection methods

Chemical disinfection

Chlorine disinfection: Disinfection is carried out using chemicals such as chlorine gas, water chlorination, sodium hypochlorite (commonly bleach) or chloramines. Chlorine disinfection is very effective in killing a wide range of microorganisms and is widely used in drinking water treatment and wastewater treatment.

Ozone disinfection(ozone generator): Uses ozone gas to oxidize organic matter and microorganisms in water. Ozone disinfection is often used in applications where water quality requires a higher standard, such as in the water bottle filling process.

Physical disinfection

Ultraviolet (UV) Disinfection: The use of ultraviolet light to irradiate a water source to kill microorganisms in the water.UV disinfection does not require the addition of chemicals and is commonly used in drinking water treatment and swimming pool water disinfection.

Thermal disinfection: Water is heated to a high temperature to kill bacteria and viruses. This is used for disinfection in some cases, but is less commonly used due to the high energy consumption and complexity of the operation. In some industrial applications, thermal disinfection may be used to remove microorganisms from water, especially if high temperatures are required.

Other disinfection methods

Electrolytic Disinfection: Chlorine ions or hypochlorite are produced by electrolysis and used to disinfect water. This method is usually used in small-scale water treatment systems.

Ozone oxidation: In addition to being used as a decontamination method, ozone also oxidizes organic matter and microorganisms in the water to provide disinfection.

These disinfection methods follow different principles and operations to disinfect water sources and ensure that water quality meets safety standards. The choice of disinfection method usually depends on the characteristics of the water source, the disinfection effect to be achieved, and economic and environmental considerations.

Key differences between decontamination and disinfection

| Features | Decontamination | Disinfection |

| Objective | Remove various pollutants from water such as solid particles, organic compounds, chemicals, etc., to make it cleaner. | Eliminate or remove microorganisms like bacteria, viruses, fungi from water to reduce the risk of disease transmission. |

| Methods | Employ physical or chemical methods such as filtration, sedimentation, adsorption, or chemical treatment to remove contaminants. | Use chemical disinfectants, UV light, ozone, or other methods to kill or remove microorganisms from water. |

| Application Area | More widely used to remove various types of pollutants including solids, chemicals, organic matter, etc. | Primarily used to kill microorganisms, especially in scenarios requiring assurance of drinking water or direct contact with water sources. |

Recommendations for decontamination and disinfection

Decontamination and disinfection are crucial steps in the water treatment industry, especially when it comes to ensuring safe drinking water and treating wastewater. The following are recommendations for the water treatment industry:

Decontamination recommendations

- Regular inspection and maintenance of equipment: Regularly inspect filters, sedimentation tanks, chemical treatment equipment, etc. to ensure their normal operation and efficient performance.

- Comprehensive application of various decontamination technologies: Different pollutants require different treatment methods, and comprehensively apply filtration, adsorption, chemical treatment and other technologies to achieve better decontamination results.

- Strictly control the operation process: Strictly follow the operation procedures and standards to ensure the stability and reliability of the decontamination process.

- Continuous improvement and updating technology: water treatment technology is constantly developing, timely grasp of new technologies and methods, and constantly optimize and improve the water treatment process.

Disinfection recommendations

- Choose a suitable disinfection method: Choose a suitable disinfection method, such as chlorine disinfection, UV disinfection or ozone disinfection, according to the characteristics of the water source, the usage scenario and the water quality standard to be achieved.

- Strictly control the concentration of disinfectant and contact time: Ensure that the concentration of disinfectant and the contact time meet the specified standards to ensure the disinfection effect.

- Regular monitoring of disinfection effectiveness: Test water samples regularly to ensure that the disinfection effectiveness meets the requirements, e.g. microbial concentration meets the standards.

- Maintain equipment and disinfection system: Regularly check and maintain the disinfection equipment to ensure that it is working properly to guarantee the disinfection effect.

Summary

Decontamination and disinfection play a vital role in the water treatment industry. Decontamination works to remove contaminants from the water, guaranteeing clean, pure water, while disinfection focuses on destroying microorganisms in the water, reducing the risk of disease transmission. Together, they ensure the safety and hygiene of water sources, not only for drinking water, but also play a key role in the industrial, environmental and public health sectors.

KUOSI can supply not only disinfection equipment and wastewater screens, but also blowers, sludge dryers, sludge dewatering equipment and dosing systems, so please contact us if you have any questions.