Clarification in water treatment is a crucial process that effectively removes suspended solids and particulate matter from water, improving its clarity and overall quality. Whether for drinking water purification or wastewater treatment, clarification plays an essential role in ensuring water safety and environmental health. This blog will explain the role of clarification, its basic principles, and common clarification technologies, while also discussing the key equipment used throughout the process.

The Basic Principles of Clarification

Clarification is a physical and chemical process that removes solid particles and impurities from water, making it clearer. The clarification process typically involves the following stages:

Coagulation

Coagulation is the first step in the clarification process, where coagulants (such as alum or iron salts) are added to water to neutralize the charge of suspended particles. Once the particles lose their charge, they clump together to form larger particles known as “flocs.” The coagulation tank plays a key role in evenly distributing the coagulants throughout the water, allowing for effective particle aggregation.

Flocculation

After coagulation, the water enters the flocculation stage. In this phase, the water is gently stirred to help the smaller coagulated particles combine into larger flocs. Flocculation increases the size of the particles, making them easier to remove. The flocculation tank or flocculator uses mechanical stirring or water flow to promote the agglomeration of particles.

Sedimentation

After flocculation, the water enters the sedimentation tank. Here, gravity causes the heavier flocs to settle at the bottom. The clarified water rises above the sediment and moves on to the next treatment stage. The design of the sedimentation tank, including water flow velocity, significantly influences the efficiency of sedimentation.

Filtration

The water, after sedimentation, often passes through a sand filter to remove any remaining small particles. For further purification, an activated carbon filter can be used to remove organic substances and odors. A multi-media filter offers a more advanced filtering method, removing even finer particles from the water.

Disinfection

After clarification, the water typically undergoes disinfection to kill any remaining bacteria and pathogens. Common disinfection methods include UV sterilization and chlorination. These methods ensure that the water meets safety standards before it is used or released.

The Importance and Role of Clarification

Clarification is not just an important step in the water treatment process; it directly impacts the safety and efficiency of water purification. The primary roles of clarification include:

- Removal of suspended solids: Clarification effectively removes suspended solids and particulate matter from water, reducing turbidity.

- Improving the efficiency of subsequent processes: By removing a significant portion of the particles, clarification reduces the burden on filtration and disinfection processes, improving overall treatment efficiency.

- Ensuring water safety: Clarification removes harmful substances and microorganisms, ensuring that the water is safe for consumption or use. In drinking water treatment, it creates optimal conditions for the disinfection process.

- Reducing pollutants in wastewater: In wastewater treatment, clarification removes harmful suspended solids, oils, and other contaminants, ensuring that the effluent meets environmental standards before being discharged.

Applications of Clarification Technology

Clarification technology is widely used in various water treatment systems, particularly in the following areas:

- Drinking water purification: In municipal drinking water treatment plants, clarification is a common initial treatment method. It helps remove impurities and ensures the water meets health and safety standards.

- Wastewater treatment: Clarification is commonly used in industrial wastewater and municipal sewage treatment systems to remove suspended solids and pollutants, reducing the environmental impact of wastewater discharge and making it suitable for further treatment.

- Waterbody restoration: Clarification can also be applied in waterbody restoration projects to remove sediment and pollutants from lakes, rivers, and reservoirs, improving the water quality and clarity.

Key Equipment in the Clarification Process

Various equipment works together in the clarification process to ensure effective treatment. Here are some of the most commonly used pieces of equipment:

Coagulation and Flocculation Tanks

These tanks are responsible for evenly distributing coagulants and promoting floc formation. They use mechanical stirring or carefully controlled water flow to ensure particles agglomerate properly.

Sedimentation Tanks

Sedimentation tanks are where flocs settle to the bottom due to gravity. The clarified water, now free of most suspended solids, moves to the next stage of filtration. The design of the sedimentation tank, especially the flow rate, is crucial for effective clarification.

Sand Filters and Multi-Media Filters

After sedimentation, water often passes through a sand filter to remove any remaining fine particles. Multi-media filters provide higher filtration efficiency by using several layers of filtration media, ensuring a higher degree of clarity.

Dissolved Air Flotation (DAF) Units

In some wastewater treatment systems, DAF units are used to remove oil and light particles. Air is dissolved in the water, and tiny air bubbles attach to the particles, causing them to float to the surface for removal.

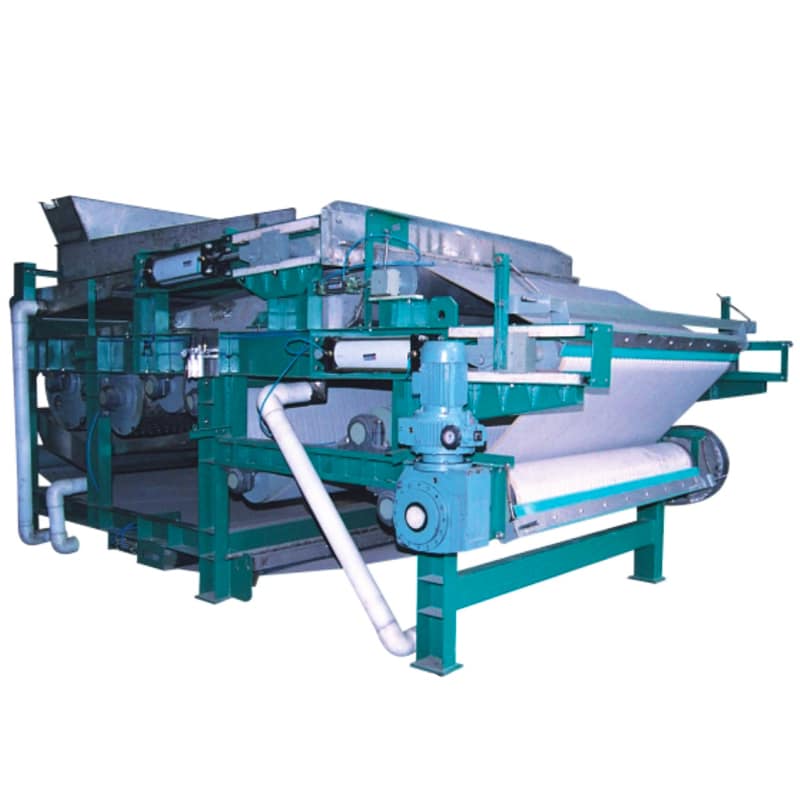

Sludge Treatment Equipment

The sludge that accumulates in the sedimentation process must be further treated. Sludge thickening tanks and belt filter presses are commonly used to reduce the volume of sludge, making it easier to handle and dispose of.

Disinfection Equipment

Finally, UV sterilizers or chlorination systems are used to disinfect the clarified water, ensuring the removal of any remaining microorganisms and pathogens.

Summary

Clarification is a critical step in water treatment, involving multiple pieces of equipment working in tandem. Through coagulation, flocculation, sedimentation, filtration, and disinfection, clarification improves water clarity and ensures its safety. As water treatment technologies advance, the equipment and processes for clarification are continuously optimized to improve efficiency, reduce energy consumption, and lower operational costs. Selecting the right equipment and technology is crucial for ensuring that water treatment systems operate effectively and sustainably.

KUOSI offers sludge dryers, sludge conveyors, dosing systems, aeration blowers, wastewater screens, compactors, scrapers, etc. in addition to sludge dewatering equipment, DAF systems and disinfection equipment. Please contact us for further information.