Sludge Drying

What is sludge drying?

Sludge drying is a sludge treatment process in which the water in the sludge is removed as water vapor by heating. It significantly reduces the volume and weight of the sludge, making it easier to recycle and reuse.

Purpose of sludge drying

Dried sludge can be recycled for a variety of uses, such as fertilizer, compost by-products or fuel for incineration plants.

Weight and volume reduction

Removing as much water as possible from the sludge by evaporation reduces the weight and volume of the sludge, making it easier to store and transport.

Stabilization of sludge

Drying stabilizes sludge, thereby reducing olfactory nuisance and improving disinfection, while making it less likely to leak during transport.

Easier recovery

Disposed sludge can be recycled for agricultural fertilizer.

Easier sludge treatment

Drying can reach the minimum dry content levels required by law for use in cement plant ovens. It also increases the calorific value of the sludge used for incineration.

Sludge drying methods

In the sludge drying process, the water is not removed in liquid form by mechanical means (e.g. in thickening or dewatering). Therefore the sludge is usually dried to a solids concentration above 60% to produce granules, or to a powder at a maximum solids concentration of 90%. Granular or powdered sludge is easier to convey than dewatered sludge with higher moisture content, which is present in bulk form.

This sludge drying process includes both direct and indirect methods. Indirect thermal drying is used to reduce the sludge volume by removing the moisture content and achieving a 90% dry solids content. This process reduces the environmental impact and produces a stable dried granular product that can be easily stored and transported and is suitable for agricultural use.

Dryers are usually classified according to the primary method of transferring heat to the wet solid being dried. These methods are conduction (indirect drying), convection (direct drying) and radiation (infrared drying).

A large amount of air is not required in the contact drying process, because warmth is provided by the contact between the moist product and the heated wall. Usually only a minimal gas flow is planned to exhaust the vapors. The advantage of this is that the cost of exhaust gas cleaning is minimal.

Convection drying obtains its effect by treating the sludge with hot air. In addition, ambient air is heated to high temperatures using a burner or steam heat exchanger and brought into contact with the sludge in a drum or belt dryer.

The distinctive feature of radiation drying is that the heat required for the drying process is supplied to the sludge by radiation. General examples of heating by radiation are solar radiation or infrared heating elements.

We offer two different types of sludge drying systems:

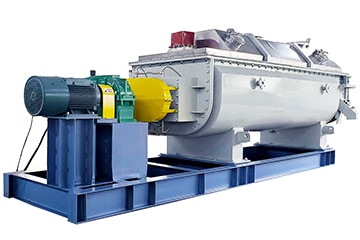

- Hollow paddle dryer — Horizontal agitator dryer with heat transfer. The drying process only needs a small amount of gas to take away the moisture, which greatly reduces the loss of this part of the heat taken away by the gas and improves the utilization rate of heat, it is suitable for the drying of granular and powder materials, and can also dry paste materials smoothly.

- Low temperature sludge drying system — Combined heat pump drying host, closed drying room, sludge automatic conveyor belt and automatic control system in one. Closed cycle system, zero emission and no bad smell, not affected by external climate: gradient dehumidification, low air volume, low temperature drying, fast drying and no dust; with heat recovery function, significantly improve energy utilization efficiency.