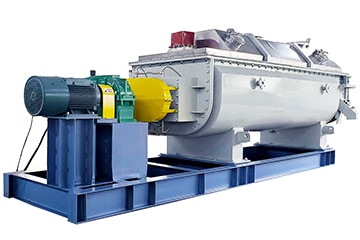

Sludge Dryer

Sludge dryers dry wastewater sludge to reduce its mass and save on sludge transportation and disposal costs. Dried sludge is easy to handle and store, all further processing and utilization methods are possible, and the dried product can be used as fertilizer and fuel.

KUOSI is a manufacturer and supplier of sludge dryer machine in China. The manufactured sludge dryers are designed for small, medium and large sludge generating units. These dryers can be installed to load directly underneath a filter press or multiple disk screw press, or elsewhere in the plant. The sludge is dried through the heated liner of our units while being crushed and circulated through our screw blade system. The dryer liner uses an indirect heat source from steam, electric hot plates or gas fires. Our pre-heated airflow system draws moisture out of the top of the internal dryer and discharges it through our wet scrubber system. Typically after 3-6 hours of drying time (depending on the type and moisture content of the sludge), the dried material is removed for gravity discharge into a container by simply opening the discharge panel below the unit. Another option is to include a screw conveyor to move the sludge into the elevated container.

Our use and indirect heating provides a uniform heating surface and allows for tighter temperature control, making it less likely to cause sludge burning or insidious combustion. It also eliminates the dangers associated with open flames.

Purpose of sludge drying

The limitations of mechanical sludge drying sometimes require thermal drying through water evaporation. Drying sludge makes it suitable for recycling or destruction, allowing the sludge to be recycled for a variety of uses, such as fertilizer, compost by-products or fuel for incineration plants.

- Weight and volume reduction

Removing water from sludge by evaporation reduces the volume and weight of sludge, making it easier to store and transport. - Stabilization of sludge

Drying stabilizes sludge, thereby reducing olfactory nuisance and improving disinfection. - Easier recovery

By evaporating the water, the end product can be prepared for use in a composting facility. This means that the sludge can be recycled for agricultural use. - Easier sludge treatment

Drying can reach the minimum dry content levels required by law for use in cement plant ovens. It also increases the calorific value of the sludge used for incineration.

Applications

- Chemical sludge

- Industrial sludge

- Hazardous sludge

- Municipal sludge

- Food waste

- Other high moisture and viscosity materials