Screw press is an important mechanical device that has revolutionized many industries through its efficient dewatering, compression and extraction capabilities. From agriculture to waste management, screw presses have earned widespread recognition for their versatility, reliability and efficiency.

What Is A Screw Press?

A screw press is a mechanical device that utilizes a screw mechanism to apply pressure to extract liquids from various materials or compress them into a desired shape. The technology has its origins in antiquity, but has undergone significant development to suit the needs of modern industry.

Mechanical Principle of Screw Press

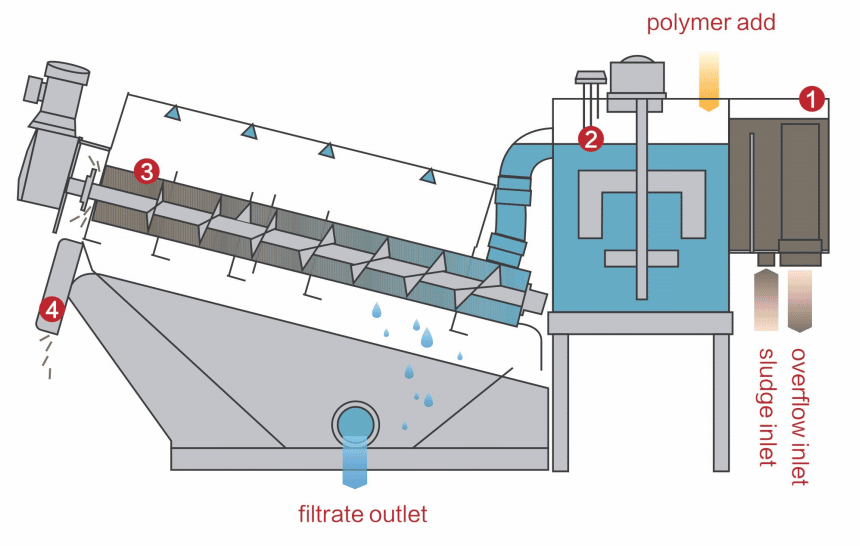

The mechanical principle of screw presses is based on the mechanism of screw propulsion and compression and is mainly used for dewatering, pressing or separating materials. The following is a detailed description of the working principle of the screw press:

Screw propulsion

- Screw shaft: Inside the screw press is a screw shaft (or screw propeller) that rotates along the length of the barrel. The spiral blades of the screw shaft continuously push the material from the inlet to the press area.

- Material transportation: The material is pushed towards the press area by the rotating action of the screw shaft. The design of the screw shaft can be gradual, i.e. the pitch of the screws is gradually reduced to increase the compression of the material.

Compression and dewatering

- Pressing zone: As the material is pushed into the pressing zone, the pitch of the auger shafts is gradually reduced to compress the material. The compression causes the water to be pushed out of the material.

- Screen: The press is equipped with an internal screen (or strainer) that allows the liquid (water) to flow through the screen while the solid material is compressed within the screen.

- Increasing pressure: As the material moves along the screw shaft, the pressure in the press area gradually increases, further compressing the material and squeezing out more liquid.

- Liquid discharge: The liquid (e.g. waste water) that passes through the screen flows out into a collection tank or discharge system.

Operational adjustments

- Screw speed: The rotational speed of the screw shaft can be adjusted to control the conveying and compressing effect of the material.

- Screw blade design: The angle and shape of the screw blades can be designed according to different materials to optimize the pressing effect.

- Screen aperture: The aperture of the screen can be adjusted to control the discharge speed of liquid and the separation effect of solid materials.

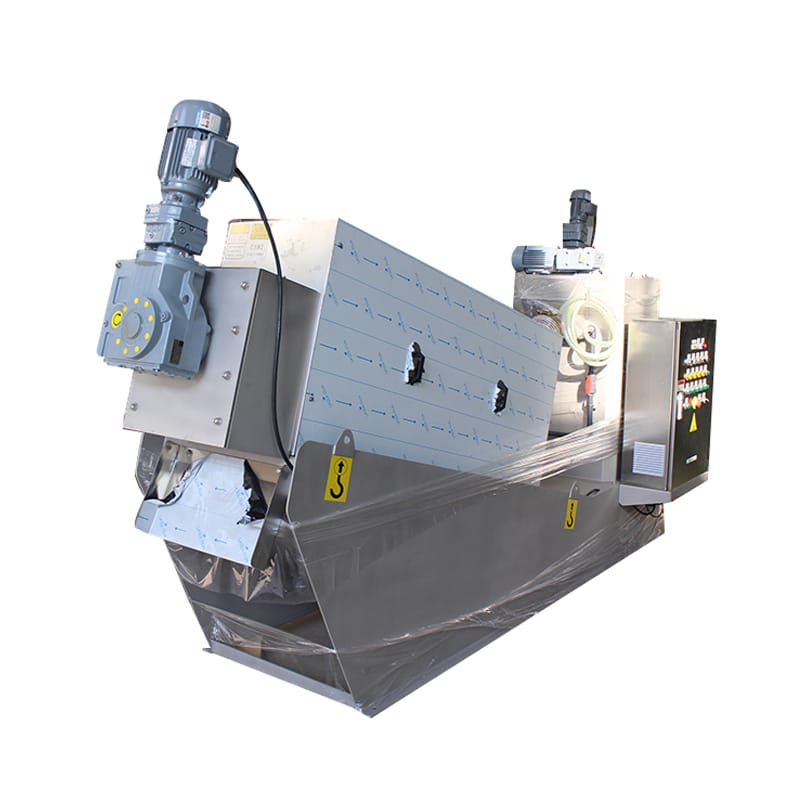

Screw Press Components

- Spiral: Main component for applying pressure.

- Cylinder: Holds the screw and material for the extraction and compression process.

- Motor: Provides the power to rotate the spiral, ensuring continuous operation.

- Sieve: Allows liquid to be discharged while retaining solid material.

- Outlet: Discharges the processed material.

Types of Screw Presses

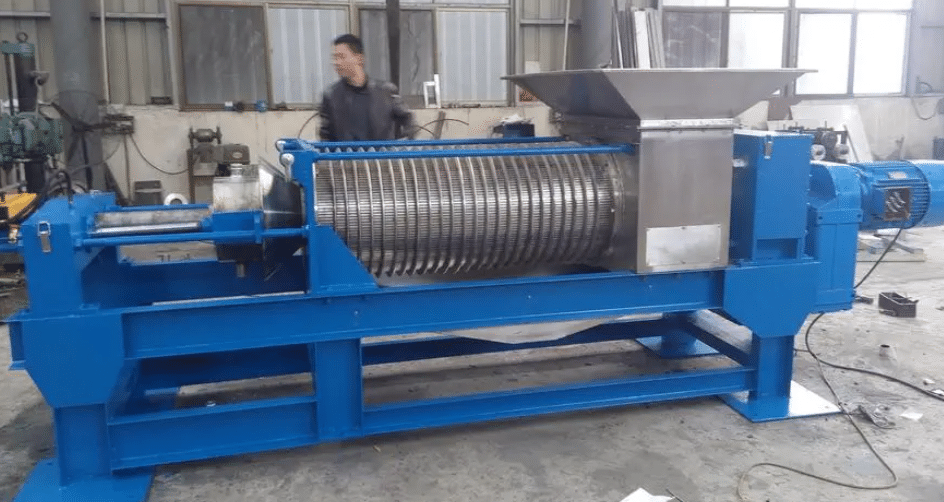

Single Screw Press

This type of press has a single screw and is commonly used in dewatering applications such as wastewater treatment plants.

Twin Screw Press

Use two interlocking augers for more demanding applications such as extracting juice from fruits and vegetables or processing high fiber materials.

Horizontal and Vertical Screw Press

The classifications refer to the orientation of the screws and cylinders and affect the footprint of the press and its ability to fit into different operating environments.

Screw Press Applications

Agriculture

In agriculture, screw presses are used to extract oil from seeds, juice from fruits and to dehydrate livestock manure, reducing waste volume and creating valuable by-products such as animal feed.

Waste Management

Screw presses play a key role in the wastewater treatment process, dewatering sludge, reducing disposal costs and creating waste products that are easier to handle.

Food and Beverage Industry

From juicing fruits and vegetables to extracting vegetable oils, screw presses are critical to maintaining product quality and maximizing yields.

Industrial applications

In industrial environments, screw presses are used to dewater pulp, sludge, process biofuels and compress recyclable materials.

Advantages of Using Screw Presses

- Efficiency: continuous operation with minimal downtime ensures high throughput and productivity.

- Versatility: Handles a wide range of materials from high moisture to high fiber content.

- Cost effectiveness: By efficiently dewatering and compacting materials, the screw press reduces disposal costs and increases the value of by-products.

- Environmental impact: Screw presses promote sustainable practices by reducing waste volume and enabling recycling of materials.

Key Considerations for Selecting a Screw Press

Material characteristics: Knowing the nature of the material to be treated, such as moisture content and fiber structure, is critical to selecting the right screw press type and configuration.

Volume requirements: Evaluating the volume of material to be processed will help determine the size and power of the press required to meet production demands.

Maintenance and operating costs: Evaluating the maintenance requirements and operating costs of a screw press can impact long-term profitability and efficiency.

Quality and reliability: Investing in a high quality, reliable screw press ensures continued performance and durability.

FAQs

What maintenance does a screw press require?

Routine maintenance includes inspecting and replacing wear parts, lubricating moving parts, and ensuring screen holes are clean to maintain optimum performance.

Can a screw press handle high moisture materials?

Yes, screw presses are ideally suited to handle materials with high moisture content, from which they can efficiently extract liquids.

Do screw presses consume a lot of energy?

The energy consumption of screw presses is relatively low, especially with modern, energy-efficient models. The improvement of energy efficiency is also an important direction for future development.

Summary

Screw presses continue to be an indispensable technology in a variety of industries, offering unrivaled efficiency, versatility and cost-effectiveness. By understanding its mechanics, applications and benefits, companies can fully utilize the potential of this remarkable machine to increase productivity and sustainability.

The brand KUOSI is committed to providing you with a full range of solutions. This includes not only state-of-the-art screw presses, but also highly efficient filter presses, precise dosing systems, reliable disinfection systems, innovative sludge dryers, flexible sludge conveyors, powerful air-floaters, energy-efficient aeration blowers, fine wastewater screens, and highly efficient mud scrapers. Whatever your needs, KUOSI can provide you with the best quality equipment and service. Contact us today and let us help you enhance your production and realize higher operational efficiency!