In the field of industrial wastewater management, choosing the right sludge dewatering technology is critical to ensure operational efficiency and cost-effectiveness. Screw presses and filter presses are the two main solutions, each with their own unique advantages and specific operational needs.

Differences in Dewatering Technology

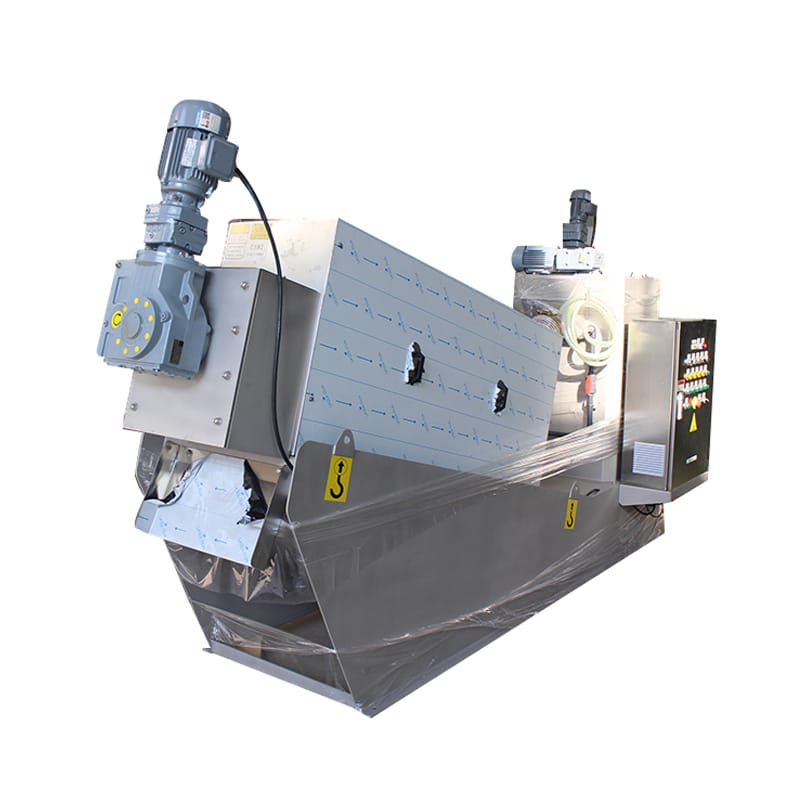

Screw Press

- Mechanism: Expulsion of liquid using a rotating screw that exerts pressure on the sludge inside a cylindrical screen.

- Output: A drier cake-like substance is produced as a result of the gradual increase in pressure.

- Application: For application scenarios that require continuous operation with minimal operator intervention.

Filter Press

- Mechanism: By pumping sludge into a chamber surrounded by filter cloths, pressure is used to push water through the cloths, leaving a solid cake.

- Output: Typically results in lower water content.

- Application: Suitable for batch processing of sludge with a high solids content.

Comparison of Sludge Dewatering Performance

For a clearer comparison, let’s look at the effectiveness and efficiency of these two technologies for sludge dewatering:

| Technology | Moisture Content (%) | Operational Speed | Suitability |

| Screw press | 75-85% | Fast | Organic & fibrous sludge |

| Filter press | 60-80% | Moderate | Inorganic & dense sludge |

Operation and Maintenance of Screw Presses and Filter Presses

Screw Press

- Operation: Automated operation with less need for monitoring.

- Maintenance: Lower maintenance costs due to fewer parts.

Filter Press

- Operation: More manual monitoring required, especially during setup and batch discharge.

- Maintenance: Higher maintenance requirements due to many components such as plates and cloths.

Cost Impact

Screw presses: Typically have lower operating costs due to reduced labor and maintenance expenses.

Filter presses: While initial setup may be cost effective, long-term operation and maintenance may be more expensive.

Environmental Impact

Screw presses: Use less energy and water, making them a more environmentally friendly option.

Filter presses: Higher water usage and more waste may be generated due to disposable filter cloths.

Summary

The choice between a screw press and a filter press is based on the specific needs of your sludge dewatering process, including the type of sludge, the desired level of dryness of the output, operational flexibility and cost considerations. At KUOSI, we offer screw presses and filter presses, as well as other complementary equipment such as sludge dryers and conveyors to complete your dewatering needs. If you need professional advice and quality equipment to improve the efficiency of your operation, please feel free to contact us.

To learn more about how KUOSI can help you optimize your wastewater management and dewatering processes, please visit our website or contact our team of experts. We are here to help you find the perfect solution for your needs!