In the field of sludge treatment, choosing the right solid-liquid separation equipment is crucial. Screw presses and centrifuges are two common types of equipment, each with its own unique advantages.

Power Consumption

Screw Presses

Low energy consumption: Screw presses have a simple design and usually use a mechanical screw to apply pressure, so their energy consumption is relatively low. They are suitable for long runs and have a stable energy consumption, especially when processing high solids content materials.

Centrifuges

Higher energy consumption: Centrifuges rely on high rotational speeds to generate centrifugal force, which provides high separation efficiency but requires large amounts of electrical power to maintain high rotational speeds. As a result, centrifuges typically consume much more energy than screw presses, especially when running for long periods of time.

Durability

Screw Presses

Strong durability: the structure of screw press is relatively simple, with few moving parts, low wear and tear, and relatively easy to maintain. With regular maintenance, screw presses can run stably for a long time and have a long service life.

Centrifuges

Relatively more fragile: Since centrifuges involve high-speed rotation, internal parts are subjected to higher stress, especially key components such as bearings and seals, which are prone to damage due to prolonged high-load operation. As a result, centrifuges typically require more frequent maintenance and higher maintenance costs.

Noise Level

Screw Presses

Lower noise level: Due to the slower running speed and smoother mechanical movement of the screw press, the noise level is relatively low, making it suitable for environments where noise control is a requirement.

Centrifuges

Higher noise levels: Centrifuges generate higher noise levels due to their high speed rotation, especially during high power operation, and may require additional soundproofing to minimize the impact of noise on the surrounding environment.

Percentage of Dry Matter

Screw presses: dry matter percentages are typically between 15% and 30% and are suitable for handling materials with high moisture content.

Centrifuges: dry matter percentages can be 40%-60% or higher, suitable for applications requiring a high degree of dewatering.

Notes:

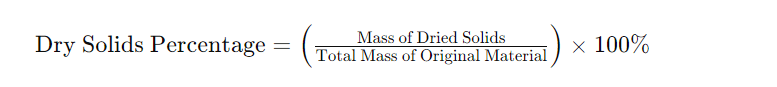

Dry Solids Content Percentage (DS) is the mass of solids in a given material as a percentage of the total mass of the material. This indicator is often used to characterize the moisture content of a material and is an important parameter in assessing the degree of drying and treatment of a material.

Specifically, the dry solids percentage can be calculated using the following formula:

Position Requirement

Screw Presses

Flexible location: Screw presses can be installed more flexibly in a wide range of environments due to their compactness and low vibration and noise levels. No special infrastructural support is required and they do not need to be located far from the work area.

Centrifuges

Location is demanding: centrifuges usually need to be installed in specialized isolated rooms or in more remote areas due to their high noise and vibration levels. In addition, centrifuges need to be installed in locations that take into account vibration damping and soundproofing, and usually require a more solid foundation to support the high speeds of the equipment.

Maintenance

Screw Presses

Low maintenance requirements: simple structure, few moving parts, routine maintenance is mainly cleaning and inspection, low cost.

Centrifuges

High maintenance requirements: involves high speed rotating parts, fast wear and tear, requires frequent inspection and maintenance, high cost.

Service Life

Screw Presses

Long life: usually lasts 10 years or more due to its simple design.

Centrifuges

Shorter service life: high rotational speeds lead to faster wear and tear of the components, usually with a service life of 5-8 years.

Comparison of Other Performance Technical Parameters of Screw Presses and Centrifuges

| Parameter/Feature | Screw Press | Centrifuge |

| Processing Capacity | Several cubic meters per hour | Several hundred to thousands of liters per hour |

| Motor Power | 5-30 kW | 15-150 kW |

| Operating Pressure/Speed | 0.5-3 MPa | 2000-6000 rpm |

| Footprint | Larger, requires more installation space | Smaller, but higher installation requirements |

| Operating Temperature Range | Operates at ambient temperature | Can adapt to high-temperature operations |

| Material Compatibility | High solid content, fibrous materials | Fine particle materials |

Summary

Screw presses are suitable for most industrial sludge treatment applications due to their low energy consumption, ease of maintenance, long service life and installation flexibility. Centrifuges, on the other hand, are suitable for applications that require efficient separation and processing of high percentages of dry matter, but have higher requirements in terms of energy consumption, noise and vibration. Choosing the most appropriate equipment for your specific needs will significantly improve treatment efficiency and cost effectiveness.

KUOSI specializes in providing one-stop solutions for sludge treatment. We offer a wide range of efficient equipment such as sludge dewaterers, sludge dryers, sludge conveyors, aeration blowers, dosing systems, disinfection systems, wastewater screens, grit removal equipment, scrapers and more. If you need further assistance or consultation, please feel free to contact us and the KUOSI team will customize the optimal solution for you.