Multi disc screw presses are changing the way industries handle dewatering processes. Whether you are in wastewater treatment, food processing, or the pulp and paper industry, this technology offers unmatched efficiency, cost-effectiveness, and operational reliability.

What is A Multi Disc Screw Press?

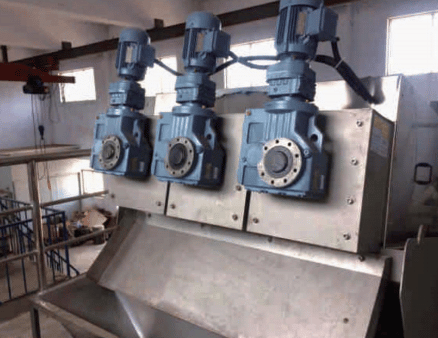

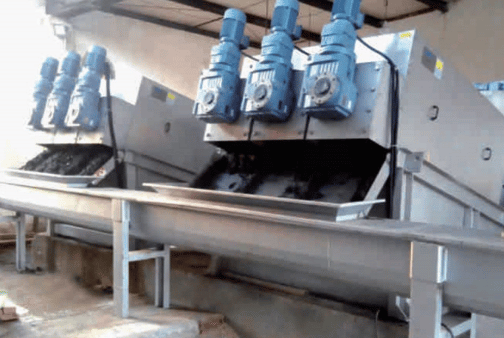

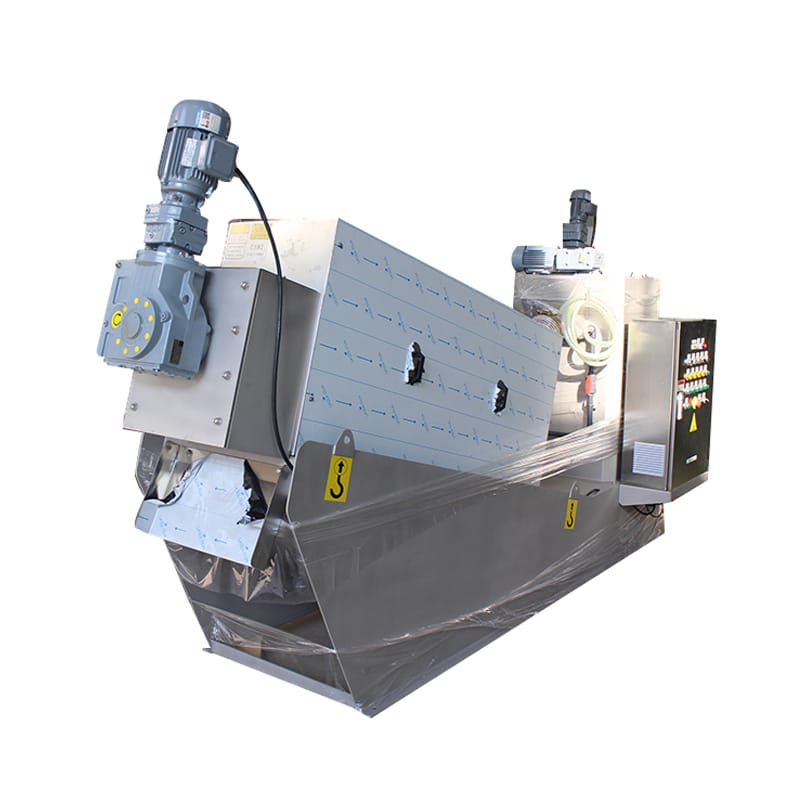

The Multi Disk Screw Press is a state-of-the-art machine for separating solids and liquids. It efficiently extracts liquids and leaves a dry solid ” sludge cake ” by using a screw conveyor and multiple filter discs (or disks) to compress and filter the material together.

Main Features of Multi Disc Screw Press

- Energy saving and high efficiency: Running at low speed with very low energy consumption.

- Continuous operation: Can operate 24 hours a day, suitable for large-scale continuous treatment processes.

- Compact design: Small footprint for facilities with limited space.

- Low Maintenance Requirements: Design includes self-cleaning filter disks to reduce clogging and maintenance.

- Wide applicability: Capable of treating a wide range of materials from municipal sludge to industrial waste.

Working Principle of Multi Disc Screw Press

First, the sludge or slurry to be treated is fed into the inlet of the unit. As needed, a flocculant may be added to the material to help aggregate the particles and thus improve separation efficiency.

Next, the material enters a screw conveyor. This spiral device is surrounded by multiple discs (or filter disks) that are secured to the screw shaft, creating multiple filter zones. The screw shaft rotates slowly, pushing the material along the length of the device. During this process, the material is continuously compressed and filtered, and the liquid is gradually squeezed out and discharged through the gaps between the disks. At the same time, the solid material is compressed into a more concentrated sludge cake, which is delivered to the end of the machine as the screw is pushed forward.

At the end of the machine, the dewatered solid “cake” is discharged, while the separated liquid (called filtrate) is collected and discharged from the system. This process can be continuous, allowing the plant to operate 24 hours a day for large scale processing needs.

Multi Disc Screw Press vs. Traditional Dewatering Methods

| Feature | Multi Disc Screw Press | Centrifuge | Belt Press |

| Energy consumption | Low: Approximately 0.2-1.5 kW | High: Approximately 15-60 kW | Medium: Approximately 3-10 kW |

| Maintenance requirement | Low: Self-cleaning, minimal upkeep | High: Frequent balancing and adjustments | Medium: Regular belt cleaning required |

| Footprint | Compact: About 1-5 square meters | Large: About 10-20 square meters | Large: About 15-30 square meters |

| Dewatering efficiency | High: Solids content 20-35% | High: Solids content 20-45% | Medium: Solids content 15-25% |

| Noise level | Low: Approximately 55-70 dB | High: Approximately 80-100 dB | Medium: Approximately 70-85 dB |

| Operational continuity | Continuous: 24/7 operation | Batch: Requires downtime for cleaning | Batch: Requires downtime for cleaning |

How Many Times More Efficient is a Multi Disc Screw Press?

Multi Disc Screw Presses typically have higher dewatering efficiencies than Single Disc Screw Presses. Although the specific multiplier varies depending on equipment type and application conditions, in general, a Multi Disc Screw Press can be two to three times more efficient than a Single Disc Screw Press.

The following is a simplified comparative example:

- Multi-disc screw press: solids content typically up to 20-35%.

- Single-disc screw press: solids content typically 15-25%.

Multi-Disc Screw Presses for Various Industry Applications

- Municipal wastewater treatment

- Food and beverage processing

- Paper and pulp industry

- Chemical and pharmaceutical industry

- Agriculture and livestock

Summary

With their efficient dewatering performance, low energy consumption and maintenance requirements, multi-disc screw presses are suitable for handling large-scale materials in a number of industries and are particularly suited to application scenarios where high capacity and high dewatering efficiency are required.

Welcome to KUOSI, your preferred partner in water treatment. We offer a full range of high quality equipment including sludge dewatering equipment, sludge dryers, sludge conveyors, dosing systems, disinfection systems, DAF systems, aeration blowers and wastewater screens. Each product is carefully designed and rigorously tested to ensure that it meets your needs.