Industrial reverse osmosis (RO) is a water purification technology used in a variety of industries to remove impurities and provide high quality water. Its applications range from desalination to wastewater treatment, making it an integral process in modern industrial operations. This guide explores the principles, benefits, challenges and future trends of industrial reverse osmosis.

History and Evolution of Reverse Osmosis

The concept of reverse osmosis has evolved significantly since its inception. membrane technology was first explored in the early 1900’s, but it wasn’t until the 1950’s that practical applications emerged. Advances in materials and engineering have transformed reverse osmosis into a powerful and efficient solution for industrial water treatment.

What Is Industrial Reverse Osmosis?

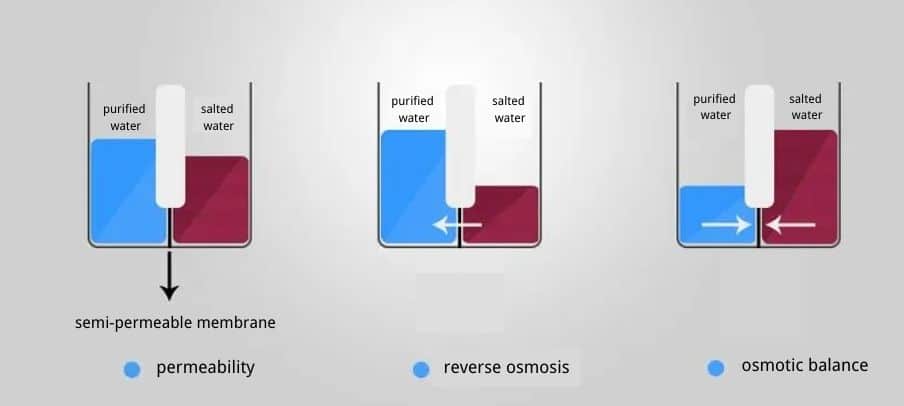

Industrial reverse osmosis is a water purification method that uses a semi-permeable membrane to separate contaminants from water. By applying pressure, water molecules pass through the membrane while impurities are trapped. This process effectively removes a wide range of contaminants including salts, organic molecules and microorganisms, producing high purity water suitable for industrial use.

Working Principle of Industrial Reverse Osmosis

The heart of industrial reverse osmosis lies in the membrane process. Water is pressurized to overcome the natural osmotic pressure, forcing it through a semi-permeable membrane. The membrane allows water molecules to pass through while rejecting larger contaminants. The result is pure water on one side and concentrated wastewater, or brine, on the other.

What Does Reverse Osmosis Remove From Water?

The following are the major components that can be removed from water by reverse osmosis (RO) technology and their removal rates:

| Type of Impurity | Specific Components | Removal Rate (%) |

| Dissolved Salts and Minerals | Sodium (Na), Calcium (Ca), Magnesium (Mg), Potassium (K), Iron (Fe), Manganese (Mn), Sulfates (SO₄²⁻), Chlorides (Cl⁻), Carbonates and Bicarbonates (CO₃²⁻ and HCO₃⁻) | 95-99 |

| Organic Substances | Natural organic matter (e.g., humic acids and fulvic acids), synthetic organic compounds (e.g., pesticides, herbicides), Dissolved Organic Carbon (DOC) | 90-99 |

| Microorganisms | Bacteria, viruses, protozoa, spores | 99+ |

| Inorganic Contaminants | Heavy metals (e.g., lead Pb, mercury Hg, cadmium Cd, arsenic As), fluorides (F⁻), nitrates (NO₃⁻), boron (B) | 90-99 |

| Suspended Solids and Particles | Fine silt, rust, colloids | 99+ |

| Chemical Pollutants | Chlorine (Cl₂), ammonia nitrogen (NH₃-N), cyanides (CN⁻) | 90-99 |

| Radioactive Elements | Uranium (U), radium (Ra) | 95-99 |

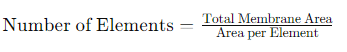

Design Calculations for Industrial RO Systems

Designing an industrial reverse osmosis (RO) system requires understanding several key performance parameters and performing various calculations to ensure its efficiency and effectiveness. The following is a detailed guide:

Key performance parameters:

Recovery rate:

Recovery rate is the percentage of incoming water that is converted to produced water (transmissible water).

Formulas:

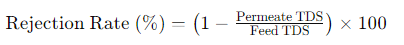

Desalination rate:

Desalination rate is the percentage of dissolved solids removed from the feed water.

Formulas:

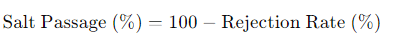

Salt transmission rate:

Salt transmittance indicates the percentage of dissolved salt that passes through the membrane.

Formulas:

Flux rate:

Flux rate measures the flow rate of water produced per unit of membrane area.

Formulas:

Key Components of Industrial Reverse Osmosis Systems

- Membrane: The heart of the system, responsible for filtering out contaminants.

- Pump: Provides the pressure needed to drive water through the membrane.

- Pressure vessel: Holds the membrane and supports high pressure operation.

- Piping: guides water through the system.

- Control system: monitors and manages operations to ensure optimal performance.

Types of Membranes Used in Industrial Reverse Osmosis

- Thin film composite (TFC): Known for its high rejection rate and durability.

- Cellulose acetate membranes: Offer good chlorine resistance, but lower performance than TFC.

- Nanocomposite membranes: Incorporate nanoparticles for improved performance and fouling resistance.

Industrial Reverse Osmosis Applications

- Water treatment: Provides clean water for industrial processes.

- Desalination: Converts seawater into fresh water, essential for water-scarce areas.

- Wastewater recycling: Treating industrial wastewater for reuse.

- Food and beverage industry: Ensuring high purity water for production processes.

- Pharmaceutical manufacturing: Meeting the stringent water quality standards for pharmaceutical production.

Challenges and Limitations of Industrial Reverse Osmosis

- Fouling: Contaminants build up on the membrane surface.

- Energy consumption: High pressure requirements can lead to significant energy usage.

- Maintenance requirements: Regular maintenance is required to maintain system performance.

What Role Does Industrial Reverse Osmosis Play in Pre- and Post-Treatment?

The Role of Reverse Osmosis in Pretreatment

- Improved treatment effectiveness:

Reverse osmosis is primarily used in the pretreatment stage to remove dissolved salts, organic matter, microorganisms and other dissolved contaminants from water. This step can significantly reduce the total dissolved solids (TDS) of the water and improve the efficiency of the subsequent treatment unit. - Pollution reduction:

By removing most of the dissolved salts and contaminants through pretreatment, the load on subsequent equipment (e.g., ion exchangers, nanofiltration equipment, etc.) can be reduced, extending the service life of such equipment and reducing the frequency of maintenance and replacement. - Reduce treatment costs:

Through reverse osmosis pretreatment, it can reduce the amount and frequency of the use of chemicals, such as softeners, oxidizers, etc., thus reducing the overall treatment costs.

The Role of Reverse Osmosis in Post-treatment

- Final purification:

After reverse osmosis treatment, the water quality has been greatly improved. However, in some demanding applications (e.g. electronics industry, pharmaceutical industry, etc.), further removal of very minute amounts of dissolved substances and residues is required. After reverse osmosis, the water is then treated with ion exchange, EDI (electrodeionization), etc., and can reach the standard of ultrapure water. - Ensure stable water quality:

Reverse osmosis system in the post-treatment stage can ensure the stability of the effluent water quality, to avoid fluctuations in water quality on the final product or process impact. - Increase safety:

The water after reverse osmosis can be further killed by ultraviolet disinfection, ozone treatment and other microorganisms to ensure the microbiological safety of water, especially for drinking water and food industry.

FAQs

What is the difference between industrial reverse osmosis and domestic reverse osmosis?

Industrial RO systems are designed for large-scale applications and higher flow rates, while domestic systems are smaller and used for personal water purification needs.

How can I reduce energy consumption in an industrial reverse osmosis system?

Energy consumption can be reduced by implementing energy recovery systems, selecting high efficiency pumps and optimizing operating conditions.

How often are industrial reverse osmosis systems maintained?

Regular maintenance is usually required, such as monthly, quarterly or annually, depending on system usage and water quality conditions.

What is membrane contamination in Industrial Reverse Osmosis and how can it be prevented?

Membrane contamination is the process of contaminant buildup on the membrane surface and can be prevented by proper pretreatment and regular cleaning.

What is the typical payback period for an industrial reverse osmosis system?

The payback period depends on the size of the system, the initial investment, and the operating costs, but is usually between 2 and 5 years.

Summary

Industrial reverse osmosis technology is at the heart of modern water treatment, and KUOSI brand solutions provide comprehensive support for this technology. Our product range includes highly efficient pre-treatment equipment to ensure stable water quality; advanced sludge dryers and sludge dewaterers to enhance treatment efficiency; accurate dosing systems and DAF systems to optimize the treatment process; reliable wastewater screens and sludge conveyors for automated treatment; and high-performance scrapers and disinfection systems to ensure safe water quality. By choosing KUOSI, you will receive leading technical support and quality equipment to help your industrial water treatment system achieve optimal performance. Contact us today to learn more about our products and solutions and we will be happy to assist you!