Solids removal is a critical step in ensuring that water quality meets environmental standards. Whether in industrial wastewater treatment, drinking water purification, or municipal wastewater treatment, solids removal not only improves water quality, but also protects the proper operation of water treatment equipment. This paper will explore the different approaches, applications, and challenges of solids removal.

Common Methods of Solids Removal

Sedimentation

Sedimentation is one of the most basic solids removal methods, separating solids from liquids by allowing particles in the water to naturally sink to the bottom. This method is usually applied in the primary stage of water treatment and is suitable for removing larger particles. Common settling tanks include primary and secondary settling tanks.

Filtration

The filtration method utilizes different filtration media (e.g. sand, activated carbon, membranes, etc.) to retain suspended and solid particles in the water. This method not only effectively removes suspended particles, but also removes some dissolved pollutants and is widely used in drinking water treatment and wastewater treatment. Membrane filtration technology (e.g. microfiltration, ultrafiltration, reverse osmosis) is an important technology developed in recent years, which is especially suitable for high-precision solids removal.

Flotation

Flotation removes light solid particles from water by introducing air bubbles into the water, causing them to float to the surface. This method is commonly used to treat wastewater with grease, foam or light suspended solids, and is particularly suitable for food and petrochemical industries.

Coagulation and Flocculation

Coagulation and flocculation is a treatment method in which suspended fine particles are aggregated into larger particles by the addition of chemicals (e.g. coagulants, flocculants). By forming “flocs”, the solid particles become larger and can be easily removed by settling or filtration. This method is often used to treat highly turbid water and is widely used in drinking water treatment and wastewater treatment.

Solids Removal Equipment and Technology

Sedimentation Tanks and Settling Tanks

Settling basins and settling tanks are the most basic equipment in the solids removal process. They help remove larger solids particles from water through the principle of natural settling. Settling tanks are usually designed as larger vessels with slower water flow rates to allow solids particles to sink sufficiently.

Filter Tanks

A filter tank is a commonly used solids removal device that captures suspended solids in water through a filter media (e.g., sand, activated carbon, membranes). Filter tanks are widely used in areas such as drinking water purification and wastewater treatment to remove finer particles. Modern filtration technologies, such as reverse osmosis and ultrafiltration membrane systems, provide higher precision solids removal.

Air Flotation Equipment

Air flotation equipment helps solid particles in the water float to the surface by injecting tiny bubbles into the water, which are then collected. This type of equipment is particularly useful for removing oil and grease, suspended solids, and lightweight materials from water. Air flotation equipment is commonly used in industries such as industrial wastewater treatment and food processing.

Related equipment:

KUOSI Air Flotation Plant: KUOSI’s air flotation plant is ideal for treating high concentrations of mixed oil and water wastewater. Its highly efficient bubble generation system effectively separates grease and suspended particles and can ensure the removal of fine pollutants from wastewater. Air flotation plants are widely used in the petroleum, chemical and food processing industries and help to significantly reduce the concentration of pollutants in wastewater.

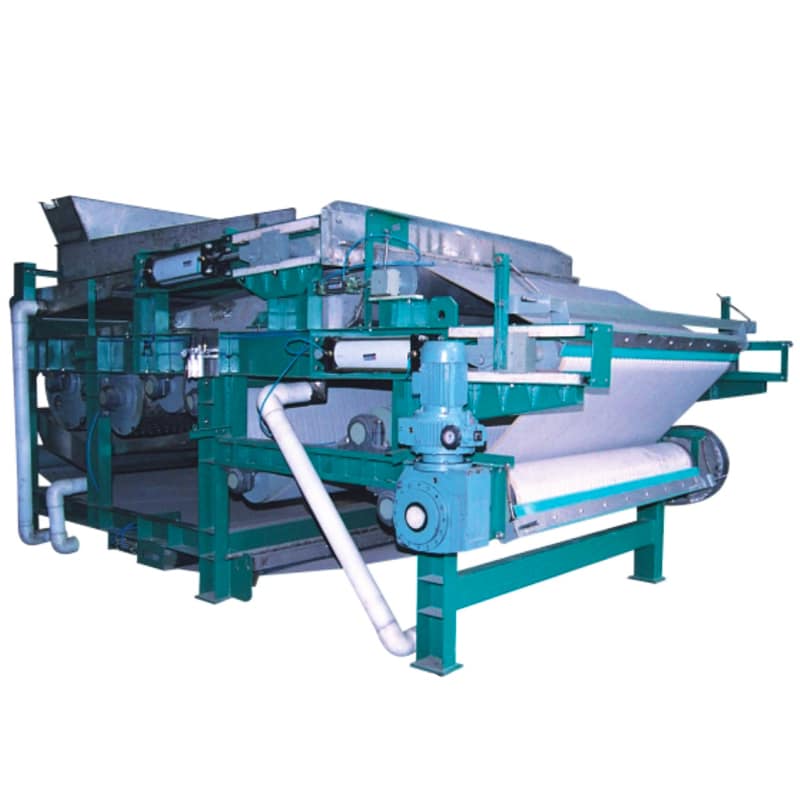

Belt Filter Presses and Centrifugal Dehydrators

Belt Filter Presses and Centrifugal Dewaterers are used for the treatment of sludge generated from solids removal processes. They remove water from sludge by compression or centrifugal force, reducing the volume of sludge. Belt filter presses are suitable for low concentration sludge, while centrifugal dewaterers are commonly used to treat high concentration sludge.

Related equipment:

KUOSI Belt Filter Press: KUOSI’s belt filter presses compress sludge and reduce water efficiently, making them particularly suitable for treating large-scale sludge, which is widely used in municipal wastewater and industrial wastewater treatment. Through advanced filter press technology, belt filter presses can effectively reduce sludge volume and sludge disposal costs.

Membrane Technology

Membrane technology (e.g. microfiltration, ultrafiltration, nanofiltration, reverse osmosis) has become an important solids removal technology, especially in the field of high-precision water treatment. By means of semi-permeable membranes, membrane technology can effectively remove tiny particles, dissolved matter and bacteria from water. Membrane filters are increasingly used in water treatment, especially in drinking water purification and industrial wastewater treatment.

Solids Removal in Various Fields

Industrial Wastewater Treatment

Industrial wastewater often contains large amounts of suspended solids, grease and chemicals. Solids removal can effectively reduce solid pollutants in water and minimize the impact on the environment. For example, air flotation is commonly used in the food processing industry to remove oil and grease, while sedimentation and filtration are commonly used in the chemical industry to remove suspended solids.

Related equipment:

KUOSI Air Flotation Equipment: Through efficient bubble generation and suspended solids separation technology, KUOSI air flotation equipment can help industrial wastewater to meet the environmental discharge standards, widely used in the treatment of grease wastewater and wastewater containing solids.

KUOSI Belt Filter Presses: Suitable for sludge treatment and removal of suspended solids from wastewater, especially at high loads, they are effective in reducing the amount of sludge and suspended solids in the wastewater produced during the treatment process.

Municipal Wastewater Treatment

Solids removal in municipal wastewater treatment is generally categorized into primary, secondary and tertiary treatment. In primary treatment, sedimentation is used to remove large solids; in secondary treatment, biological treatment degrades dissolved organic matter, while solids removal relies on settling and filtration to remove remaining suspended solids. Tertiary treatment further purifies the water and removes fine particulate matter.

Drinking Water Purification

Drinking water purification is much more demanding and often utilizes multi-stage filtration systems and coagulation and flocculation to remove fine particles, bacteria and contaminants from the water. Through these methods, solid contaminants are effectively removed from the water source to ensure safe drinking water.

Solids Removal Challenges and Solutions

Solids removal technology also faces a number of challenges during implementation:

Treatment Efficiency

Although existing technologies can effectively remove most solids particles, traditional settling and filtration methods may not be effective for some smaller, fine solids particles. In recent years, the introduction of membrane technology has effectively improved the accuracy of solids removal, but has also resulted in higher equipment and maintenance costs.

Sludge Treatment

The solids removal process generates a large amount of sludge, which needs to be treated and disposed of. How to effectively reduce the volume of sludge and make it safe for disposal is an important issue in water treatment. Through sludge dewatering and resource utilization technologies, it is possible to reduce the volume of sludge discharged and convert it into a useful resource.

Cost and Energy Efficiency

Efficient solids removal technologies are often accompanied by high equipment investment and operating costs. With the increasing demand for energy saving and environmental protection, the development of more energy efficient and effective solids removal technologies has become a key research direction for the industry.

Summary

Solids removal is an integral part of the water treatment process. As technology continues to advance, methods and equipment for solids removal are evolving to address water pollution more efficiently and economically. However, as the types and concentrations of pollutants increase, it remains a great challenge for the water treatment industry to further improve treatment effectiveness and reduce environmental burdens.

KUOSI not only provides air flotation machines and filter presses, but also other sludge dewatering machines, sludge dryers, sludge conveyors, dosing systems, aeration blowers, disinfection systems, wastewater screens, grit removal equipment, scrapers and decanter centrifuges. Please contact us if you need.