Filter press pilot testing is a critical step in determining the feasibility and effectiveness of using a filter press in a given application, which allows engineers and operators to evaluate various parameters and optimize the filtration process before investing in a full-size system.

What’s filter press pilot testing?

Filter press pilot testing is a small-scale test or trial of a filter press prior to actual application. During filter press pilot testing, samples are typically tested using samples to evaluate the performance, efficiency and suitability of the filter press under specific conditions. The purpose of such pilot tests is to simulate actual operating conditions and to verify that the design and parameters of the filter press meet the expected requirements so that necessary adjustments and improvements can be made before it is put into large-scale production.

Why filter press pilot testing?

- Verification of design parameters: The pilot test can verify whether the design parameters of the filter press, such as the area of the filtration zone, filtration pressure, filtration time, etc., meet the requirements of actual production.

- Evaluate the processing capacity: The pilot test can evaluate the processing capacity of the filter press, including the flow rate of the processed liquid, the yield of solids, the humidity of the filter cake and so on.

- Optimize the operation process: By adjusting the operation parameters and process, the production efficiency can be improved, energy consumption can be reduced, and waste generation can be reduced.

- Identify problems and room for improvement: Pilot testing can help identify potential problems and room for improvement, such as uneven cake structure, clogged filter cloths, and leaks.

- Reduce risks and costs: By identifying and solving problems in small-scale trials, significant time and cost savings can be realized.

The main purpose of the filter press pilot test is to evaluate the performance, efficiency and suitability of the filter press in practical applications.

Filter Press Pilot Test Preparation

Recessed Chamber and Diaphragm Filter Press Configuration

There are two basic filter press configurations: Concave chamber and membrane. The chamber test requires a filter press, feed pump and mixing tank with mixer. Membrane testing requires all the equipment needed for the chamber test, plus a compressed gas source for membrane extrusion and the necessary equipment to control the membrane extrusion.

Filter Cloths

In process applications, the initial quality of the filtrate and the release of the filter cake are usually prioritized in the selection of the filter cloth. In this regard, if there is a need to improve the initial filtrate quality, a slightly poorer release of the filter cake may be accepted. Conversely, for waste applications, a slightly dirty initial filtrate may be acceptable to improve cake release. In addition to these considerations when selecting a filter fabric, the chemical compatibility of the fabric material with the slurry also needs to be taken into account. This means that filter fabric selection requires some experience and may involve some trial and error.

Chemicals And Filter Aids

Chemicals and filter aids play an important role in the filtration process by increasing filtration efficiency, improving the quality of filtration and protecting the equipment. Their selection usually depends on the nature of the material to be treated and the specific requirements of filtration.

Chemicals

- Acid-base regulator: Used to adjust the pH of the material to be treated to make it more suitable for solid-liquid separation processes.

- Surfactants: Can be used to improve the dispersion of solid particles in suspension and prevent agglomeration and deposition of solid particles.

- Inhibitors: Used to inhibit the formation of undesirable reactions or precipitates that may occur during the filtration process.

Filter aid

- Silica clay: is a common filter aid, which can increase the porosity of the filter medium and improve the filtration speed and efficiency.

- Activated carbon: it can adsorb impurities and organic matter in the material to be treated and improve the filtration quality.

- Polymer gel: it can help the solid particles in the solid-liquid separation process to settle quickly and improve the filtration efficiency.

- Filter media pretreatment agent: It is used to pre-treat the filter media and improve its performance, such as improving the anti-dirt performance and abrasion resistance of the filter cloth.

Testing process

To begin the pilot filter press test program, you will need to install the filter cloth on the filter plate and place the plate into the filter press frame. Turn off the press and pressurize the hydraulic cylinders to the appropriate pressure.

How to conduct filter press pilot test?

- Sample preparation: Prepare the sample to be treated, usually a suspension or slurry containing solid particles. Ensure that the composition and properties of the sample match the actual application scenario, and pre-treat the sample as needed, such as diluting, mixing, and adjusting the pH.

- Equipment setup: Set up the filter press, including installation of filter media (filter cloth, filter plate, etc.), adjustment of filter pressure, determination of filtration time and other operating parameters.

- Test run: Inject the sample into the filter press and start the filter press for test run. Operate according to the set operating parameters and ensure the normal operation of the filter press.

- Performance evaluation: Evaluate the performance and efficiency of the filter press based on the test results. Analyze the solid-liquid separation effect, filter cake quality, processing capacity and other indicators, and compare with the expected target.

- Data analysis and report: Analyze the test data and write a report on the pilot test of the filter press.

- Adjustment and Optimization: Recommend targeted improvements based on the test results, and adjust and optimize the design and operating parameters of the filter press.

- Implementation and validation: Make necessary adjustments and improvements to the filter press based on the results of the pilot test, progressively advance to the actual production stage, and monitor the performance and stability of the filter press.

Filter Presses Suitable For Pilot Testing

Plate and Frame Filter Press: Plate and frame filter press is one of the commonly used pilot equipment, of which the recessed chamber filter press has adjustable parameters such as filtration pressure, filtration time and filter cloth tension, which is suitable for simulating different operating conditions for pilot tests.

Membrane Filter Press : Membrane filter press in the ordinary plate and frame filter press based on the addition of membrane plate, can improve filtration efficiency and solid-liquid separation performance, suitable for high-efficiency, high-quality pilot test.

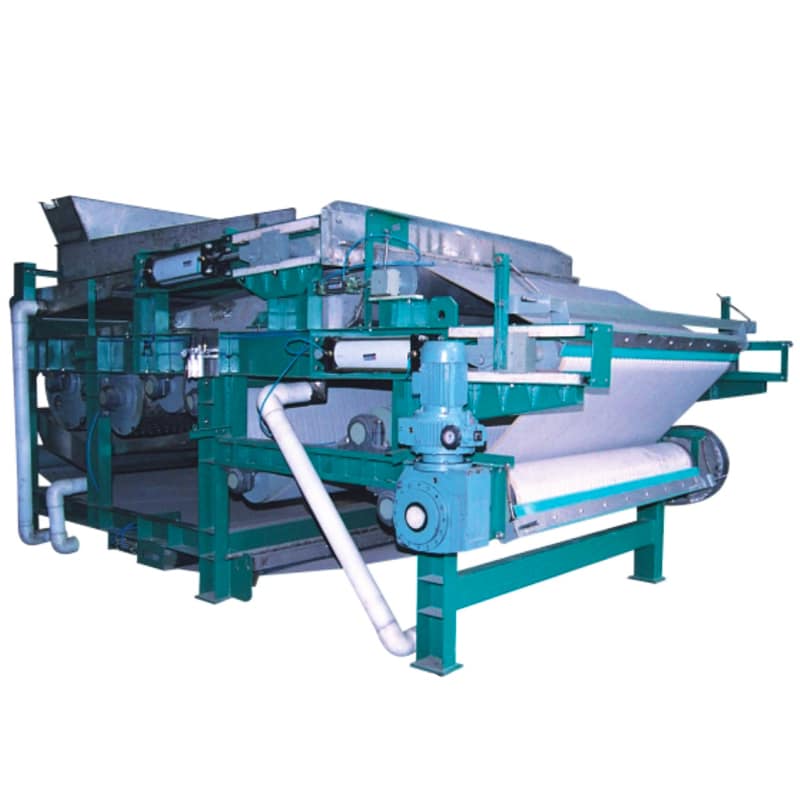

Belt Filter Press: Belt filter press utilizes filter cloth belt for continuous filtration, with stable operation performance and adjustable filtration parameters, suitable for continuous and large-scale pilot test.

Summary

The purpose of the filter press pilot test is to optimize the filter press process and improve production efficiency and product quality. Through repeated tests and data analysis, the operating parameters and equipment configuration can be continuously improved to meet the requirements of industrial production.

Kuosi is specialized in the manufacture of filter presses for sludge treatment, offering a range of filter presses, air flotation systems, aeration blower, disinfection systems and wastewater screens related to the sludge treatment process, contact us to develop an exclusive solution.